Product Description

We are professional best bevel gearbox hollow shaft 1:1, bevel gears drive hollow shaft speed increaser manufacturers and suppliers from China. All bevel gearbox hollow shaft 1:1, bevel gears drive hollow shaft speed increaser will be tested and inspection reports before products shipment.

JTP Series Cubic Bevel Gearbox

CZPT JTP series cubic bevel gearbox is also known as cubic right angle miter gearbox, cubic 90 degree bevel gearbox, cubic miter bevel gear box, or cubic spiral bevel gear reducers. JTP series cubic bevel gearbox is a right-angle shaft type gear box of spiral bevel gears for general applications with high transmission capacity, high performance and high efficiency. 1:1, 1.5:1, 2:1, 3:1, 4:1 and 5:1 gear ratios as standard. 2 way(one input 1 output), 3 way(one input 2 output, or 2 input 1 output), 4 way(two input 2 output) drive shafts as standard. CZPT shaft as standard, customize hollow shaft or motor flange to bolt an IEC motor flange. Maximum torque 1299N.m. Maximum input and output speed 1450RPM. There are 8 models: JTP65 mini cubic bevel gearbox, JTP90 cubic bevel gearbox, JTP110 cubic bevel gearbox, JTP140 cubic bevel gearbox, JTP170 cubic bevel gearbox, JTP210 cubic bevel gearbox, JTP240 cubic bevel gearbox and JTP280 cubic bevel gearbox.

| JTP65 Mini Cubic Bevel Gearbox 1. bevel gear ratio 1:1 2. CZPT drive shafts diameter12mm 3. CZPT input and output shaft shafts 4. 2 way, 3 way, 4 way gearbox 5. input power maximum 1.8Kw 6. drive torque maximum 13.5Nm 7. maximum input 156567X3, registered Capital 500000CNY) is a leading manufacturer and supplier in China for screw jacks (mechanical actuators), bevel gearboxes, lifting systems, linear actuators, gearmotors and speed reducers, and others linear motion and power transmission products. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CZPT Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications. Website 1: http://screw-jacks Website 2: /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do manufacturers ensure the compatibility of drive shafts with different equipment?Manufacturers employ various strategies and processes to ensure the compatibility of drive shafts with different equipment. Compatibility refers to the ability of a drive shaft to effectively integrate and function within a specific piece of equipment or machinery. Manufacturers take into account several factors to ensure compatibility, including dimensional requirements, torque capacity, operating conditions, and specific application needs. Here’s a detailed explanation of how manufacturers ensure the compatibility of drive shafts: 1. Application Analysis: Manufacturers begin by conducting a thorough analysis of the intended application and equipment requirements. This analysis involves understanding the specific torque and speed demands, operating conditions (such as temperature, vibration levels, and environmental factors), and any unique characteristics or constraints of the equipment. By gaining a comprehensive understanding of the application, manufacturers can tailor the design and specifications of the drive shaft to ensure compatibility. 2. Customization and Design: Manufacturers often offer customization options to adapt drive shafts to different equipment. This customization involves tailoring the dimensions, materials, joint configurations, and other parameters to match the specific requirements of the equipment. By working closely with the equipment manufacturer or end-user, manufacturers can design drive shafts that align with the equipment’s mechanical interfaces, mounting points, available space, and other constraints. Customization ensures that the drive shaft fits seamlessly into the equipment, promoting compatibility and optimal performance. 3. Torque and Power Capacity: Drive shaft manufacturers carefully determine the torque and power capacity of their products to ensure compatibility with different equipment. They consider factors such as the maximum torque requirements of the equipment, the expected operating conditions, and the safety margins necessary to withstand transient loads. By engineering drive shafts with appropriate torque ratings and power capacities, manufacturers ensure that the shaft can handle the demands of the equipment without experiencing premature failure or performance issues. 4. Material Selection: Manufacturers choose materials for drive shafts based on the specific needs of different equipment. Factors such as torque capacity, operating temperature, corrosion resistance, and weight requirements influence material selection. Drive shafts may be made from various materials, including steel, aluminum alloys, or specialized composites, to provide the necessary strength, durability, and performance characteristics. The selected materials ensure compatibility with the equipment’s operating conditions, load requirements, and other environmental factors. 5. Joint Configurations: Drive shafts incorporate joint configurations, such as universal joints (U-joints) or constant velocity (CV) joints, to accommodate different equipment needs. Manufacturers select and design the appropriate joint configuration based on factors such as operating angles, misalignment tolerances, and the desired level of smooth power transmission. The choice of joint configuration ensures that the drive shaft can effectively transmit power and accommodate the range of motion required by the equipment, promoting compatibility and reliable operation. 6. Quality Control and Testing: Manufacturers implement stringent quality control processes and testing procedures to verify the compatibility of drive shafts with different equipment. These processes involve conducting dimensional inspections, material testing, torque and stress analysis, and performance testing under simulated operating conditions. By subjecting drive shafts to rigorous quality control measures, manufacturers can ensure that they meet the required specifications and performance criteria, guaranteeing compatibility with the intended equipment. 7. Compliance with Standards: Manufacturers ensure that their drive shafts comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, provides assurance of quality, safety, and compatibility. Adhering to these standards helps manufacturers meet the expectations and requirements of equipment manufacturers and end-users, ensuring that the drive shafts are compatible and can be seamlessly integrated into different equipment. 8. Collaboration and Feedback: Manufacturers often collaborate closely with equipment manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft design and manufacturing processes. This collaborative approach ensures that the drive shafts are compatible with the intended equipment and meet the expectations of the end-users. By actively seeking input and feedback, manufacturers can continuously improve their products’ compatibility and performance. In summary, manufacturers ensure the compatibility of drive shafts with different equipment through a combination of application analysis, customization, torque and power capacity considerations, material selection, joint configurations, quality control and testing, compliance with standards, and collaboration with equipment manufacturers and end-users. These efforts enable manufacturers to design and produce drive shafts that seamlessly integrate with various equipment, ensuring optimal performance, reliability, and compatibility in different applications.

How do drive shafts enhance the performance of automobiles and trucks?Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks: 1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently. 2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance. 3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling. 4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability. 5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance. 6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance. 7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics. 8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness. 9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime. 10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance. In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

Are there variations in drive shaft designs for different types of machinery?Yes, there are variations in drive shaft designs to cater to the specific requirements of different types of machinery. The design of a drive shaft is influenced by factors such as the application, power transmission needs, space limitations, operating conditions, and the type of driven components. Here’s an explanation of how drive shaft designs can vary for different types of machinery: 1. Automotive Applications: In the automotive industry, drive shaft designs can vary depending on the vehicle’s configuration. Rear-wheel-drive vehicles typically use a single-piece or two-piece drive shaft, which connects the transmission or transfer case to the rear differential. Front-wheel-drive vehicles often use a different design, employing a drive shaft that combines with the constant velocity (CV) joints to transmit power to the front wheels. All-wheel-drive vehicles may have multiple drive shafts to distribute power to all wheels. The length, diameter, material, and joint types can differ based on the vehicle’s layout and torque requirements. 2. Industrial Machinery: Drive shaft designs for industrial machinery depend on the specific application and power transmission requirements. In manufacturing machinery, such as conveyors, presses, and rotating equipment, drive shafts are designed to transfer power efficiently within the machine. They may incorporate flexible joints or use a splined or keyed connection to accommodate misalignment or allow for easy disassembly. The dimensions, materials, and reinforcement of the drive shaft are selected based on the torque, speed, and operating conditions of the machinery. 3. Agriculture and Farming: Agricultural machinery, such as tractors, combines, and harvesters, often requires drive shafts that can handle high torque loads and varying operating angles. These drive shafts are designed to transmit power from the engine to attachments and implements, such as mowers, balers, tillers, and harvesters. They may incorporate telescopic sections to accommodate adjustable lengths, flexible joints to compensate for misalignment during operation, and protective shielding to prevent entanglement with crops or debris. 4. Construction and Heavy Equipment: Construction and heavy equipment, including excavators, loaders, bulldozers, and cranes, require robust drive shaft designs capable of transmitting power in demanding conditions. These drive shafts often have larger diameters and thicker walls to handle high torque loads. They may incorporate universal joints or CV joints to accommodate operating angles and absorb shocks and vibrations. Drive shafts in this category may also have additional reinforcements to withstand the harsh environments and heavy-duty applications associated with construction and excavation. 5. Marine and Maritime Applications: Drive shaft designs for marine applications are specifically engineered to withstand the corrosive effects of seawater and the high torque loads encountered in marine propulsion systems. Marine drive shafts are typically made from stainless steel or other corrosion-resistant materials. They may incorporate flexible couplings or dampening devices to reduce vibration and mitigate the effects of misalignment. The design of marine drive shafts also considers factors such as shaft length, diameter, and support bearings to ensure reliable power transmission in marine vessels. 6. Mining and Extraction Equipment: In the mining industry, drive shafts are used in heavy machinery and equipment such as mining trucks, excavators, and drilling rigs. These drive shafts need to withstand extremely high torque loads and harsh operating conditions. Drive shaft designs for mining applications often feature larger diameters, thicker walls, and specialized materials such as alloy steel or composite materials. They may incorporate universal joints or CV joints to handle operating angles, and they are designed to be resistant to abrasion and wear. These examples highlight the variations in drive shaft designs for different types of machinery. The design considerations take into account factors such as power requirements, operating conditions, space constraints, alignment needs, and the specific demands of the machinery or industry. By tailoring the drive shaft design to the unique requirements of each application, optimal power transmission efficiency and reliability can be achieved.

China 100%new 150 ratio speed helical worm high torque 1400 rpm reduction gearbox cycloidal speed reducer for quarry a line drive shaftError:获取session失败,

How to Identify a Faulty Drive ShaftThe most common problems associated with automotive driveshafts include clicking and rubbing noises. While driving, the noise from the driver’s seat is often noticeable. An experienced auto mechanic can easily identify whether the sound is coming from both sides or from one side. If you notice any of these signs, it’s time to send your car in for a proper diagnosis. Here’s a guide to determining if your car’s driveshaft is faulty: Symptoms of Driveshaft FailureIf you’re having trouble turning your car, it’s time to check your vehicle’s driveshaft. A bad driveshaft can limit the overall control of your car, and you should fix it as soon as possible to avoid further problems. Other symptoms of a propshaft failure include strange noises from under the vehicle and difficulty shifting gears. Squeaking from under the vehicle is another sign of a faulty driveshaft. Drive shaft assemblyWhen designing a propshaft, the design should be based on the torque required to drive the vehicle. When this torque is too high, it can cause irreversible failure of the drive shaft. Therefore, a good drive shaft design should have a long service life. Here are some tips to help you design a good driveshaft. Some of the main components of the driveshaft are listed below. U-jointYour vehicle has a set of U-joints on the driveshaft. If your vehicle needs to be replaced, you can do it yourself. You will need a hammer, ratchet and socket. In order to remove the U-joint, you must first remove the bearing cup. In some cases you will need to use a hammer to remove the bearing cup, you should be careful as you don’t want to damage the drive shaft. If you cannot remove the bearing cup, you can also use a vise to press it out. tube yokeQU40866 Tube Yoke is a common replacement for damaged or damaged driveshaft tubes. They are desirably made of a metallic material, such as an aluminum alloy, and include a hollow portion with a lug structure at one end. Tube yokes can be manufactured using a variety of methods, including casting and forging. A common method involves drawing solid elements and machining them into the final shape. The resulting components are less expensive to produce, especially when compared to other forms. end yokeThe end yoke of the drive shaft is an integral part of the drive train. Choosing a high-quality end yoke will help ensure long-term operation and prevent premature failure. Pat’s Driveline offers a complete line of automotive end yokes for power take-offs, differentials and auxiliary equipment. They can also measure your existing parts and provide you with high quality replacements. bushingThe first step in repairing or replacing an automotive driveshaft is to replace worn or damaged bushings. These bushings are located inside the drive shaft to provide a smooth, safe ride. The shaft rotates in a rubber sleeve. If a bushing needs to be replaced, you should first check the manual for recommendations. Some of these components may also need to be replaced, such as the clutch or swingarm.

in Calgary Canada sales price shop near me near me shop factory supplier High Precision Quality Wpw Speed Worm Reducer Gearbox Speed Box Jack Excavators Slew Drive Planetary Gearboxes China Manufacturer manufacturer best Cost Custom Cheap wholesaler

EPG was awarded with “renowned item of Zhejiang Province” and “well-known manufacturer of Zhejiang Province”. We are seeking forward to developing successful company associations with new customers all around the globe in the potential. We can source a total-range of electrical power transmission items like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. High EPT EPT Wpw Speed Worm EPT EPT Pace Box Jack Excavators Slew Drive Planetary GearBoxes EPT Maker

in Agadir Morocco sales price shop near me near me shop factory supplier Harvester Speed up Planetary Gearbox manufacturer best Cost Custom Cheap wholesaler

Additionally, all our creation processes are in compliance with ISO9002 standards. It has proven stable cooperation with a lot of nicely recognized universities and institutes in china this kind of as, Zhejiang College, Jilin University, Complex committee of national chain push regular, Institute of nationwide chain drive, Zhejiang software engineering materials institute, Huhan substance defense institute and it cooperated to located China Very first Car chain institute with Countrywide chain drive institute. Meanwhile, our goods are produced according to substantial high quality standards, and complying with the international advanced normal requirements. EPTer pace up planetary EPT Other type EPT as underneath for reference EPT EPT EPT

HangEPT CCMS Inc. is a skilled exporter and company of a variety of precision EPTd castings and EPTd parts in EPT. Our EPTd castings incEPT investment casting (misplaced wax casting), sand casting, die casting. We have received prosperous encounter for casting machining manufacture and gathered a team of expert staff and seasoned engineers with superior engineering amount. Our once-a-year manufacturing capacity exceeds 4,000 metric tons. We strictly put into action the ISO9000 high quality technique during the production. All our goods are nicely accepted by our consumers. Relying on our very own manufacturing unit, we can offer competitive costs, technical assistance for good quality ensure and new solution deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment with our engineering crew. If some of our items desire you, please truly feel totally free to get in touch with us at any time. Benefits: one Rich knowledge for global business, FAQ: 1. Can I be your agent? Of course, welcome to deep cooperation. We have big promotion of THINKWELL brand name in the market now. For the details you should contact me. two. Is OEM obtainable? Yes, OEM is offered. We have expert designer to assist your brand name advertising. three. How can I get a sample to check your quality? Right after price tag affirmation, you can require for samples to examine our top quality. Cost-free for the samples, but you want to spend for the freight. 4. What’s your high quality promise? We have different types of merchandise which can meet diverse high quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. 5. How about the shipping and delivery time? The delivery time is depending on the items and the amount. But EPTly, the shipping time for a container is about one month. 6. What is actually benefit will you provide? You will be satisfied with our high quality. Welcome to our company. Contact: Tel: 574 87913612 Welcome to inquiry! If any issue, truly feel free of charge to go away message on the base of this page.

in Lahore Pakistan sales price shop near me near me shop factory supplier S97-Y180L4-22-17.05 Combined Speed Variator Worm Gearbox manufacturer best Cost Custom Cheap wholesaler

assures the stability and regularity of the essential function of parts. specialize in power transmission items, CATV merchandise, mechanical seal, hydraulic and Pheumatic, and marketing items. Our merchandise assortment also handles locking assemblies (clamping factors/locking device), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes. 1 periodProduct attributes 1 period1 periodJWB-X sequence large precision speed variator with foot mounted and flange mounted 2 period of time EPT parameters

Best supplier made in China – replacement parts – PTO shaft manufacturer & factory Gearbox split shaft pto manufacturers with Double Output Shaft Gearbox for Pto Speed Increase Industrial Gearbox Types Type Transmissions Screw Jacks with ce certificate top quality low priceWe – EPG Group the most significant agricultural gearbox and pto factory in China with 5 various branches. For much more details: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

2005 kia sorento travel shaft pto shaft shields EPG kubota g1900 pto shaft significant 2001 bmw 325i travel shaft generation pto generate generator is pto mounted hydraulic pump of slip clutch pto farming italian pto shaft measurements fifteen-five hundred mark williams driveshaft horsepower tractor pto shaft standards tractor supporting equipment, mechanical cultivation, harvesting equipment and add-ons. Lower expense NMRV series worm gear utilised maritime gearbox for sale,low-cost worm gear box costs for textile machinesSolution Description NMRV Utilised Maritime Gearbox one. Mad of higher-top quality aluminum alloy,light-weight bodyweight and non-rusting two. Large output torque 3. Sleek in running and minimal in noise,can perform prolonged time in dreadful circumstances. four. Large in radiating effectiveness. 5. Good-searching in appearance,tough in provider lifestyle and tiny in volume. six. Ideal for omnibearing set up.

Firm Details

Good quality handle

Packing Packing Details: StHangZhourd carton/Pallet/StHangZhourd wood scenario Shipping and delivery Detai EPT : 15-30 doing work times on payment Our Certifications Relevant Merchandise Precision Planetary gearbox

FAQ

1.Payment Expression: TT, L/C two.Shipping time: about thirty times from obtain payment. three.We acknowledge custom-made products as for each your EPT requirement. four.Xihu (West Lake) Dis.traces for the Variety:Typically we can select 1 device which is suited for you with some informations from you,these kinds of as ratio/motor pace/mounting dimension/ out torque and so on. five.If the least get volume is in surplus of $ten thousand, there are preferential.

Q1: What data should I notify you to affirm the item? A:Product/Dimensions, Transmission Ratio, Shaft directions & Get amount. Q2: What can i do if I never know which one particular I need to have? A:Dont fear, Send out as a lot details as you can, our team will support you discover the right one particular you are searching for. Q3: What is your merchandise guarantee interval? A:We offer one year guarantee given that the vessel departure date remaining China.

Q4: Are you investing organization or maker ? A: We are factory.

Q5: How lengthy is your supply time? A: Generally it is 5-ten days if the goods are in stock. or it is fifteen-20 times if the items are not in stock, it is in accordance to quantity.

Q6: Do you offer samples ? is it cost-free or additional ? A: Indeed, we could supply the sample for cost-free demand but do not pay the expense of freight.

Q7: What is your conditions of payment ? A: Payment=1000USD, 30% T/T in EPT ,balance ahead of shippment.

If you have an additional question, p EPT really feel totally free to speak to us as under: Contact Us

Best China manufacturer & factory Belt Conveyor Gear Box planetary gear motoreductor speed increaser gearbox reverse gearbox small differential gear box With high quality best price

Our product range also covers locking assemblies (clamping elements/locking device), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

Overview

Quick Details

Supply Ability

Packaging & Delivery

Online Customization

Product Description

Product Application

Conveyor & Material Handling Mining & Quarry

Certifications

Trade Shows

Packaging & Shipping Packing Details : Standard carton/Pallet/Standard wooden case Delivery Details : 15-30 working days upon payment

Company Information

other series product

Related Products

Contact

Best China manufacturer & factory china supplier China manufacturer high torque low rpm planetary speed reducer increasing gearbox With high quality best price

More importantly, we make special parts according to supplied drawings/samples and warmly welcome OEM inquiries.

Overview

Quick Details

Supply Ability

Packaging & Delivery

Online Customization

Product Description NGW / P Series Planetary Gear Reducer Sun Gear, Planetary Gear,Internal GearRing,Staging Gear Chinese Speed Reducer widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on. NGW Series Planetary Gearbox for concrete mixer including one-stage,two-stage and three-stage, it is suitable for the required speed ratio≤1500r/min, working temperature around -40~45℃, two runs alternative in direction. P series Planetary Gearbox for concrete mixer including two-stage and three-stage, it is suitable for the required speed ratio 25-4000, the ratio will be larger in combination with R,K series reducer.

Feature:

Specification Mounting Diamensions: (please contact us for more types & model)

Model selection of right angle planetary gear box for slewing: Closely using the ideal reduction ratio. Reduction ratio = servo motor speed / reducer output shaft speed Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer. The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.planetary motor gearbox for concrete mixer.modular construction high torque planetary gearbox components.Gearbox Factory Coaxial planetary gear speed reducer for travelling gear.China gearbox manufacturer planetary speed reducer reducer gearbox.China gearbox manufacturer planetary high rpm increasing gearbox.China manufacturer high torque low rpm planetary speed reducer increasing gearbox.

Technology

China gearbox manufacturer planetary speed reducer gearbox Our Services

Chinese Speed Reducer is a mechanical transmission in many fields of theEPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools. national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. Mini Planetary Gearbox for concrete mixer. right angle planetary gear box for slewing.planetary motor gearbox for concrete mixer.modular construction high torque planetary gearbox components.China gearbox manufacturer planetary speed reducer reducer gearbox.China gearbox manufacturer planetary high rpm increasing gearbox.China manufacturer high torque low rpm planetary speed reducer increasing gearbox.

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

China gearbox manufacturer planetary speed reducer reducer gearbox. Packaging & Shipping FAQ 1.Q:Are you the factory or trading company? A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements? A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date? A:10-20 working days.

4.Q:Where is your factory? A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan. Welcome to visit us!

PTO Adapters To avoid potential connectivity issues, you may want to consider a PTO Adapter for your tractor. The PTO adapter extends the connection to the implement, providing additional space for the PTO shaft to turn without touching the Arm Weldment or other parts of your tractor or the implement.

Best China manufacturer & factory Good quality RC series helical gear box gearbox speed reducer high speed forward reverse gearbox With high quality best price

The new products include a series of high-tech and high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-speed tooth chains, timing chains, self-lubricatOur products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.ion chains, among which have type high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Details

Supply Ability

Packaging & Delivery

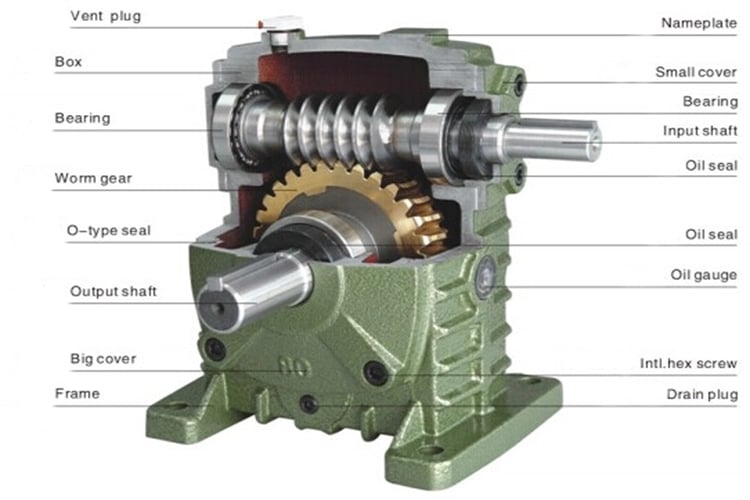

A worm gearbox consists of a cylinder with a spiral groove mounted on a shaft. A gear meshes with the spiral groove on the cylinder, and when the cylinder rotates, it causes the gear to rotate also. Online Customization

Products Description

Die-cast aluminum cabinet, light weight and good strength. The surface is specially treated, the appearance is not easy to scratch

Exquisite design, compact structure, low noise

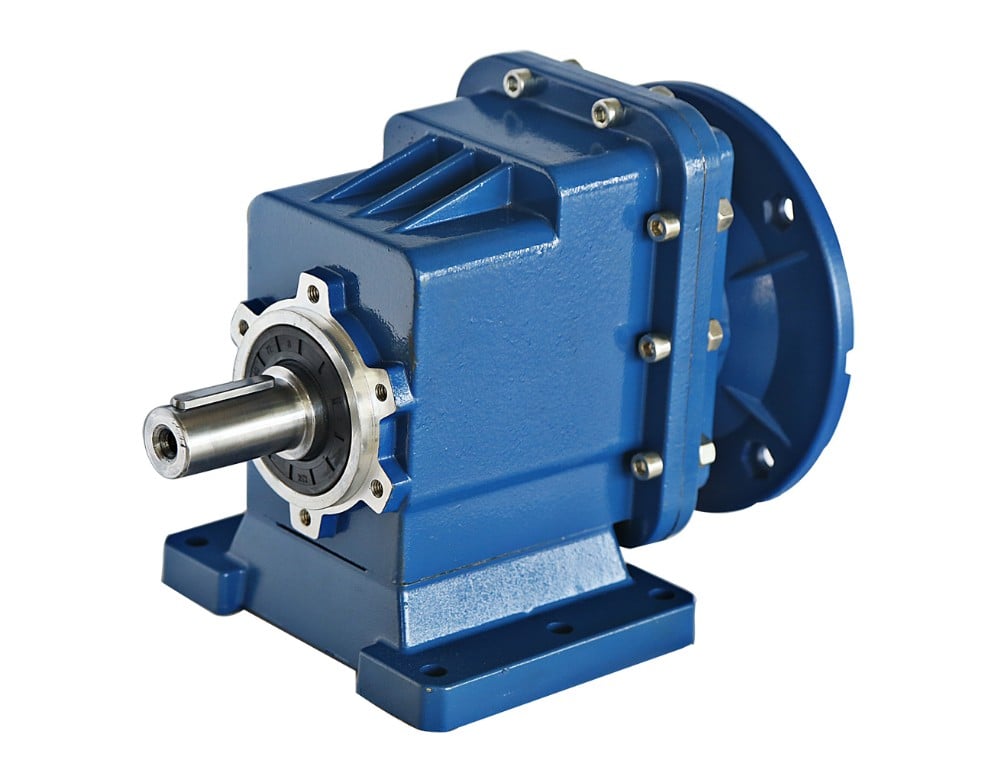

Helical gear design, tooth meshing rate is generally more than twice that of spur gears, with the characteristics of stable operation, high output torque and low backlash Related product

Company Profile

Packing & Delivery

Helical-worm China Motor Reducer S47 SF47 SA47 SAF47 SAT47 SAZ47 Helical Worm Gear Speed Reducer gearbox motor electric – Supplier Manufacturer wholesaler Factory

For a lot more information.: Cellular/Whatpp: +8613083988828 Our patented coupling mechanism C Line is the outcome of our information and growth. It permits effortless coupling and uncoupling of the PTO generate shaft. The include delivers the person more comfort because of its ergonomically and compact kind. The users’ safety is confident, simply because he can’t get entangled in protruding elements of the yoke. There is also less dust present at managing and there are fewer problems connected with it.The custom-made gearboxes developed by EPG are meant for use on a wide assortment of agricultural machinery. They have been engineered for use on products such as mowers, grain conveyors, rice harvesters, excavators, and so on.Trying to keep in head that good services is the important to cooperating with clientele, we try to satisfy higher high quality specifications, offer you competitive prices and guarantee prompt delivery. EPG main production is of farming fifteen-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Overview

Swift Particulars

Packaging & Shipping

On the internet Customization

Product Description Helical-worm Motor Reducer S47 SF47 SA47 SAF47 SAT47 SAZ47 Helical Worm Equipment Pace Reducer gearbox motor electric Merchandise SoftwareS collection sound shaft helical worm 220v ac equipment motor gearbox is 1 type of Helical worm gearbox ,created as Modularization and higher-stainless cast iron situation . It is mix of helical gear and worm equipment ,which with larger efficiency and energy than basic aluminum worm gearbox . Due to their outstanding efficiency, these drives can be used in each industrial sector and personalized to individual torque and speed demands. The equipment ratios afforded by the helical-worm equipment phase and the reduced sounds ranges for the duration of procedure make these gearmotors perfect reduced-cost solutions for basic apps

Major Features

1) Basic construction in linear type ,effortless in set up and maintation. two) Adopting innovative world renowned brand elements in pneumatic areas ,electric areas and procedure parts. 3) Substantial pressure double crank to handle the die opening and closing. 4) Operating in a substantial automatization and intellectualization,no pollution 5) Apply a linker to join with the air conveyor ,which can right inline with filling equipment .

Organization Information

Good quality management

Packing&Shipping and delivery Packing Details: Common carton/Pallet/Normal wood case Delivery Specifics : fifteen-thirty working times on payment

Our Certifications

Relevant Product

FAQ

1.Payment Phrase: TT, L/C

two.Shipping and delivery time: about 30 times from acquire payment.

3.We acknowledge custom-made merchandise as for each your particular need.

4.Guidelines for the Variety:Normally we can choose 1 equipment which is suitable for you with some informations from you,this sort of as ratio/motor speed/mounting dimension/ out torque etc.

five.If the minimum purchase quantity is in excess of $ten thousand, there are preferential.

Q1: What information should I tell you to confirm the product? A:Model/Dimensions, Transmission Ratio, Shaft directions & Order quantity.

Q2: What can i do if I will not know which 1 I need? A:Dont worry, Send out as considerably data as you can, our crew will assist you find the right 1 you are seeking for.

Q3: What is your solution warranty time period? A:We offer a single year guarantee because the vessel departure day left China.

If you have one more query, pls come to feel free to speak to us. Speak to Us

EPG – one of the largest transmission manufacturing facility in China, principal merchandise: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare areas and agricultural elements manunfacuter in China /For more info.: Mobile/Whatpp: +8613083988828

|