Product Description

|

Application |

|||||

|

• Agricultural equipment |

• Armament |

• Automobile industry |

• Computing equipment |

• Medical / dental instruments |

• Measuring instruments |

|

•Miscellaneous equipment |

•Pharmaceutical industry |

• Orthopedic implants |

• Safety equipment |

• Petrochemical industry |

• Industrial valves |

|

•Fixing and movable equipment |

• Sanitary fittings |

• General machinery |

• Pumps and general connections |

• Food and beverage processing |

• Instrumentation equipment |

|

Product Name: |

Metal Fabrication Precisely OEM Stainless Steel Gear Box Drive Shaft |

|

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ |

|

Machining Tolerance |

From 0.005mm-0.01mm-0.1mm |

|

Machined Surface Quality |

Ra 0.8-Ra3.2 according to customer requirement |

|

Applicable Heat Treatment |

T5~T6 |

|

MOQ for batch order |

For cnc machining metal parts: 50 pcs |

|

Lead Time |

7-20 days for precision drilled shaft |

|

Main Materials |

Steel: carbon steel, alloy steel, stainless steel, 4140,20#,45# ,40Cr,20Cr ,etc |

|

Aluminum: AL6061,AL6063,AL6082,AL7075,AL5052 etc. |

|

|

Stainless steel: 201SS,301SS,304SS,316SS etc. |

|

|

Brass: C37700,C28000, C11000,C36000 etc |

|

|

Surface Treatment |

Stainless Steel: Polishing, Passivating, Sandblasting, Laser engraving |

|

Steel: Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated |

|

|

Aluminum parts: Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing |

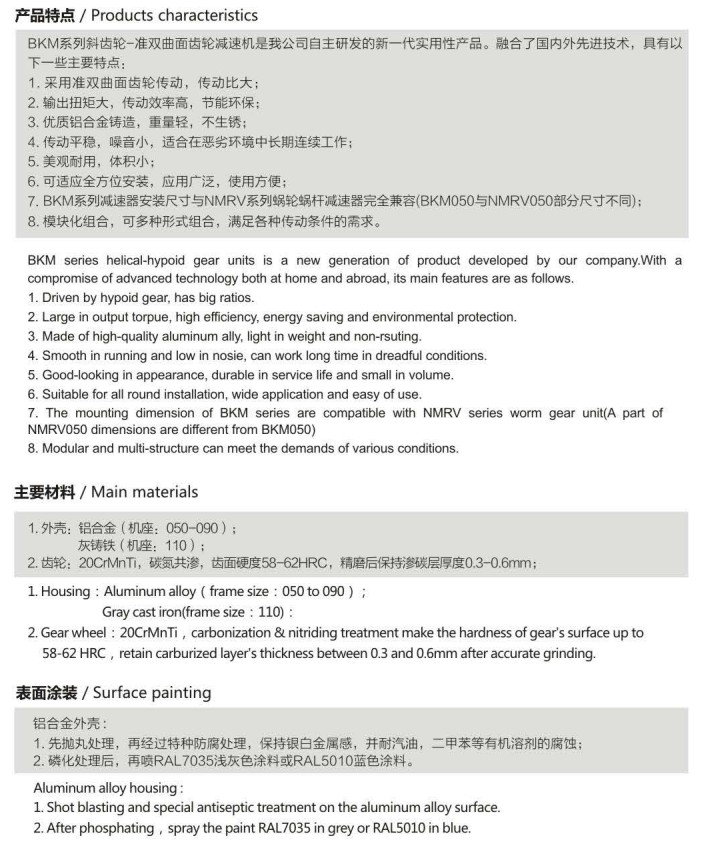

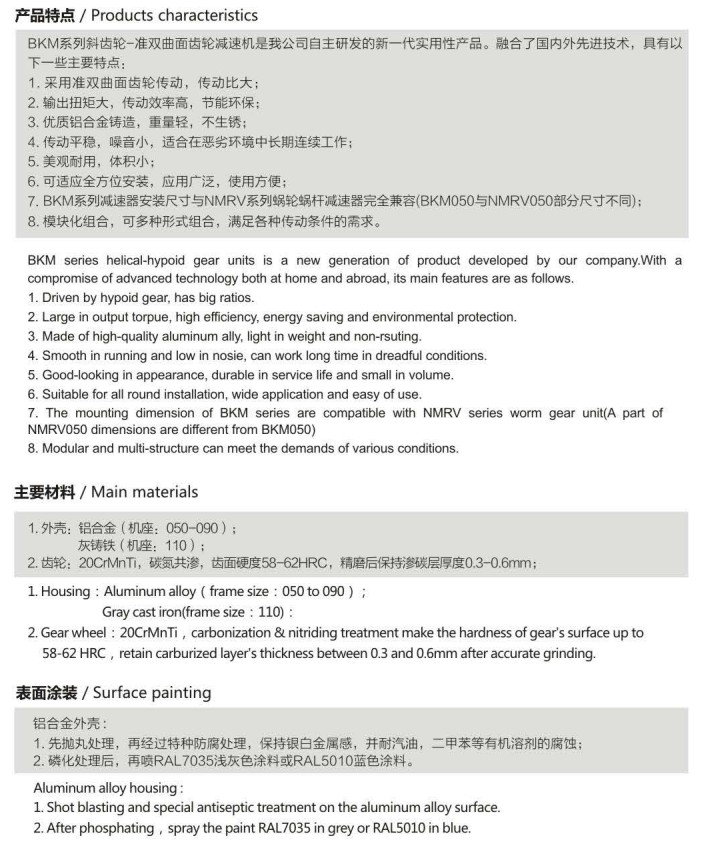

Technical Support:

ZheJiang Matech is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control:

1) Checking the raw material after they reach our factory——- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control(IPQC)

4) Checking the goods after they are finished—- Final quality control(FQC)

5) Checking the goods after they are finished—–Outgoing quality control(OQC)

Our Factory

ZheJiang CZPT Machinery Manufacture Co., Ltd.

–Branch of CZPT Industry Ltd.

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system.

With keeping manufacturing process design, quality plHangZhou, key manufacturing processes and final quality control in house.

We are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market.

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies.

These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer’s design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach.

You are welcome to contact us for technical enquiry and business cooperation.

Our Certificate

Our Customer

Our Team

Our Package

Inner Packing →Strong & waterproof plastic big is packed inside, to keep the product in safe condition.Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer’s requirements.

Related Products

FAQ

1Q: Are you trading company or manufacturer?

A: We are a factory, so we can provide competitive price and fast delivery for you.

2Q: What kind of service can you provide?

A: Our company can provide custom casting, CNC machining, surface treatment according to your requirements.

3Q: What’s kinds of information you need for a quote?

A: In order to quote for you earlier, please provide us the following information together with your inquiry.

1. Detailed drawings (STEP, CAD, CZPT Works, PROE, DXF and PDF)

2. Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, ETC.)

3. Surface treatment (powder coating, sand blasting, planting, polishing, oxidization, brushing, etc.)

4. Quantity (per order/ per month/ annual)

5. Any special demands or requirements, such as packing, labels, delivery, etc.

4Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

5Q: What makes you different from others?

A: 1. Our Excellent Service

We will submit the quotation in 48 hours if getting detailed information during working days.

2. Our quick manufacturing time

For Normal orders, we will promise to produce within 3 to 4 weeks.

As a factory, we can ensure the delivery time according to the formal contract.

6Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with photos or videos which show the machining progress.

7Q: Can I have a trial order or samples only for several pieces?

A: As the product is customized and need to be produced, we will charge sample cost, but if the sample is not more expensive, we will refund the sample cost after you placed mass orders.

8Q: Why there is tooling cost?

A: It’s mold cost. Indispensable production process. Only need to pay for first order, and we will bear maintenance cost of mold damage.

9Q: What is your terms of payment?

A: Payment of sample order ≤ 1000USD, 100% T/T full payment.

Payment of tooling or batch order ≥ 5000USD, 70% T/T in advance, balance before shipment.

10Q: What’s your after-sale service?

A: If there is quality problem, please provide photos or test report, we will replace defective goods or return funds.

If you have any other questions please find us online, or send messages via email, WhatsApp for better communication! /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Customized Shafts |

| Stiffness & Flexibility: | Flexible Shaft |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do drive shafts ensure efficient power transfer while maintaining balance?

Drive shafts employ various mechanisms to ensure efficient power transfer while maintaining balance. Efficient power transfer refers to the ability of the drive shaft to transmit rotational power from the source (such as an engine) to the driven components (such as wheels or machinery) with minimal energy loss. Balancing, on the other hand, involves minimizing vibrations and eliminating any uneven distribution of mass that can cause disturbances during operation. Here’s an explanation of how drive shafts achieve both efficient power transfer and balance:

1. Material Selection:

The material selection for drive shafts is crucial for maintaining balance and ensuring efficient power transfer. Drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, stiffness, and durability. These materials have excellent dimensional stability and can withstand the torque loads encountered during operation. By using high-quality materials, drive shafts can minimize deformation, flexing, and imbalances that could compromise power transmission and generate vibrations.

2. Design Considerations:

The design of the drive shaft plays a significant role in both power transfer efficiency and balance. Drive shafts are engineered to have appropriate dimensions, including diameter and wall thickness, to handle the anticipated torque loads without excessive deflection or vibration. The design also considers factors such as the length of the drive shaft, the number and type of joints (such as universal joints or constant velocity joints), and the use of balancing weights. By carefully designing the drive shaft, manufacturers can achieve optimal power transfer efficiency while minimizing the potential for imbalance-induced vibrations.

3. Balancing Techniques:

Balance is crucial for drive shafts as any imbalance can cause vibrations, noise, and accelerated wear. To maintain balance, drive shafts undergo various balancing techniques during the manufacturing process. Static and dynamic balancing methods are employed to ensure that the mass distribution along the drive shaft is uniform. Static balancing involves adding counterweights at specific locations to offset any weight imbalances. Dynamic balancing is performed by spinning the drive shaft at high speeds and measuring any vibrations. If imbalances are detected, additional adjustments are made to achieve a balanced state. These balancing techniques help minimize vibrations and ensure smooth operation of the drive shaft.

4. Universal Joints and Constant Velocity Joints:

Drive shafts often incorporate universal joints (U-joints) or constant velocity (CV) joints to accommodate misalignment and maintain balance during operation. U-joints are flexible joints that allow for angular movement between shafts. They are typically used in applications where the drive shaft operates at varying angles. CV joints, on the other hand, are designed to maintain a constant velocity of rotation and are commonly used in front-wheel-drive vehicles. By incorporating these joints, drive shafts can compensate for misalignment, reduce stress on the shaft, and minimize vibrations that can negatively impact power transfer efficiency and balance.

5. Maintenance and Inspection:

Regular maintenance and inspection of drive shafts are essential for ensuring efficient power transfer and balance. Periodic checks for wear, damage, or misalignment can help identify any issues that may affect the drive shaft’s performance. Lubrication of the joints and proper tightening of fasteners are also critical for maintaining optimal operation. By adhering to recommended maintenance procedures, any imbalances or inefficiencies can be addressed promptly, ensuring continued efficient power transfer and balance.

In summary, drive shafts ensure efficient power transfer while maintaining balance through careful material selection, thoughtful design considerations, balancing techniques, and the incorporation of flexible joints. By optimizing these factors, drive shafts can transmit rotational power smoothly and reliably, minimizing energy losses and vibrations that can impact performance and longevity.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery:

Drive shafts are responsible for transferring power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transmitting power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer:

Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability:

Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability:

Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction:

Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency:

Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades:

Drive shaft upgrades can be a popular performance enhancement for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications:

Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability:

Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies:

Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency,and enabling compatibility with performance upgrades and advanced technologies. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

Are there variations in drive shaft designs for different types of machinery?

Yes, there are variations in drive shaft designs to cater to the specific requirements of different types of machinery. The design of a drive shaft is influenced by factors such as the application, power transmission needs, space limitations, operating conditions, and the type of driven components. Here’s an explanation of how drive shaft designs can vary for different types of machinery:

1. Automotive Applications:

In the automotive industry, drive shaft designs can vary depending on the vehicle’s configuration. Rear-wheel-drive vehicles typically use a single-piece or two-piece drive shaft, which connects the transmission or transfer case to the rear differential. Front-wheel-drive vehicles often use a different design, employing a drive shaft that combines with the constant velocity (CV) joints to transmit power to the front wheels. All-wheel-drive vehicles may have multiple drive shafts to distribute power to all wheels. The length, diameter, material, and joint types can differ based on the vehicle’s layout and torque requirements.

2. Industrial Machinery:

Drive shaft designs for industrial machinery depend on the specific application and power transmission requirements. In manufacturing machinery, such as conveyors, presses, and rotating equipment, drive shafts are designed to transfer power efficiently within the machine. They may incorporate flexible joints or use a splined or keyed connection to accommodate misalignment or allow for easy disassembly. The dimensions, materials, and reinforcement of the drive shaft are selected based on the torque, speed, and operating conditions of the machinery.

3. Agriculture and Farming:

Agricultural machinery, such as tractors, combines, and harvesters, often requires drive shafts that can handle high torque loads and varying operating angles. These drive shafts are designed to transmit power from the engine to attachments and implements, such as mowers, balers, tillers, and harvesters. They may incorporate telescopic sections to accommodate adjustable lengths, flexible joints to compensate for misalignment during operation, and protective shielding to prevent entanglement with crops or debris.

4. Construction and Heavy Equipment:

Construction and heavy equipment, including excavators, loaders, bulldozers, and cranes, require robust drive shaft designs capable of transmitting power in demanding conditions. These drive shafts often have larger diameters and thicker walls to handle high torque loads. They may incorporate universal joints or CV joints to accommodate operating angles and absorb shocks and vibrations. Drive shafts in this category may also have additional reinforcements to withstand the harsh environments and heavy-duty applications associated with construction and excavation.

5. Marine and Maritime Applications:

Drive shaft designs for marine applications are specifically engineered to withstand the corrosive effects of seawater and the high torque loads encountered in marine propulsion systems. Marine drive shafts are typically made from stainless steel or other corrosion-resistant materials. They may incorporate flexible couplings or dampening devices to reduce vibration and mitigate the effects of misalignment. The design of marine drive shafts also considers factors such as shaft length, diameter, and support bearings to ensure reliable power transmission in marine vessels.

6. Mining and Extraction Equipment:

In the mining industry, drive shafts are used in heavy machinery and equipment such as mining trucks, excavators, and drilling rigs. These drive shafts need to withstand extremely high torque loads and harsh operating conditions. Drive shaft designs for mining applications often feature larger diameters, thicker walls, and specialized materials such as alloy steel or composite materials. They may incorporate universal joints or CV joints to handle operating angles, and they are designed to be resistant to abrasion and wear.

These examples highlight the variations in drive shaft designs for different types of machinery. The design considerations take into account factors such as power requirements, operating conditions, space constraints, alignment needs, and the specific demands of the machinery or industry. By tailoring the drive shaft design to the unique requirements of each application, optimal power transmission efficiency and reliability can be achieved.

editor by CX 2024-03-10

in San Miguel de Tucuman Argentina sales price shop near me near me shop factory supplier Ara Type Gear Box Reducer manufacturer best Cost Custom Cheap wholesaler

Owing to our sincerity in providing very best services to our clientele, comprehending of your wants and overriding sense of responsibility towards filling purchasing specifications, The team has taken portion in the generating and revising of ISO/TC100 intercontinental chain standard many a long time in good results and hosted the 16th ISO/TC100 Worldwide annual conference in 2004. There is a technological middle of province degree, EPG academician operating station, experiment station for EPG put up doctors, and national 863 software set up in EPG team. With these platforms and strong technical capacity, the more than 400 professionals have developed all range of unique higher exact and substantial strength items, performed mould packages for crucial components in the auto and national market revitalizing plan, resulting a lot more than 5000 developed in excess of, between which 33 items are autonomous patent engineering with four patent accepted . ARA EPT EPT

High performance

Competitive cost

Extensive assortment of ratio

ARA collection helical EPTl EPT straigEPT EPTl EPT

90 RigEPT Angle EPTl Gear EPT

ARA series helical EPTl EPT straigEPT EPTl EPT

hollow shaft EPTl EPT

EPT EPTl EPT

Ratio colon 1 colon1 comma1 period5 colon1 comma2 colon1 comma 2 period5 colon1 comma3 colon1 comma4 colon1 comma five colon1

Helical Equipment EPT colon 20crmntih and 17crnimo6

Shaft EPT colon 40cr Solid Steel

Helical Gear Hardness colon Hrc58-62

Equipment EPT colon Forged Iron lparEPT250 or Qt450 rpar

Weight colon two-488KG

Product Attributes colon

1 comma chassis colon substantial rigidity forged iron FC-25 semi

two comma EPT colon higher-quality high-EPT alloy quenched 50CrMnT processing by carburizing and grinding jointly semi

three comma the spindle colon high top quality alloy steel 40Cr quenched high EPT processing comma with hanging load ability time period

four comma bearing colon with a heavy load potential EPTred roller bearings semi

five comma Seal colon EPTed oil seal lips comma with a large dust and anti-spill period

Features colon

ARA collection of spiral EPTl EPTes qualities colon small comma complete set up comma mild excess weight comma EPT alloy shell comma shaft requires the use of corrosion-resistant metal when buying interval Lubricant has been included at the manufacturing facility time period

ARA Collection modular steering box using EPT design and style comma features substantial EPT gear sector is an indispensable item period of time ARA series steering box excellent overall performance comma gentle bodyweight comma tiny measurement comma conXiHu (West Lake) Dis.Hu (West Lake) Dis. material semi rugged comma high high quality EPT alloy die casting semi appearance comma affordable design comma reverse procedure comma input and output using multi-dimensional composition comma and the output varied methods period For a wide variety of torque comma minimal sounds comma EPT daily life time period

EPT parameters colon

EPT colon period018KW ~ four period94KW

Torque colon 6 period95 ~ forty six period8Nm

EPT ratio colon 1 colon1 comma two colon1

As a leaEPTmanufacturer of EPT motors comma velocity EPTs comma EPTs and so on in EPT comma our firm has alwaEPTbeen adhering to the quot top EPT innovation comma attaining excellent quality quot concept comma the main products are colon Micro EPT motors comma medium-dimension EPT motors comma Brake pace regulating motors comma torque motors comma DC motors comma NMRV worm motor comma helical EPTl EPT motors comma WP RV series worm EPT comma rigid tooth flank helical EPT units comma Helical worm EPT units comma PXiHu (West Lake) Dis.Hu (West Lake) Dis.lel shaft helical EPT models comma Spiral EPTl EPT models comma SWL amp JW Worm screw jack comma Rigid tooth flank EPT units comma Planetary EPT units and so on EPT products comma which are extensively used in various EPT production traces comma This kind of as transportation EPTry comma food EPTry comma healthcare EPTry comma printing EPTry comma textile EPTry comma EPT EPTry comma business office products comma instrumentation and other fields comma is the desired supporting goods for EPT equipments period

| ration | 1 colon1 comma1 period5 colon1 comma2 colon1 comma two period5 colon1 comma3 colon1 comma4 colon1 comma five colon1 |

in Diwaniyah Iraq sales price shop near me near me shop factory supplier Nmrv 063 Gear Motor Actuator Reducer Chain Drive Gear Box 1 1 Ratio 90 Degree Gear Box Hitachi Excavator Slewing Gearbox manufacturer best Cost Custom Cheap wholesaler

“We are constantly serving our customers with our ideal merchandise.” EPG has established up a total set of high quality administration technique which is supplied with superior inspection and examination gear. we have received the have confidence in of consumers throughout the world.

Minimal EPT NMRV collection worm EPT used maritime EPT for sale,low cost worm EPT box rates for textile EPTs

Product Description

NMRV Utilized Maritime EPT

1. Mad of high-high quality EPT alloy,ligEPT weigEPT and non-rusting

2. Massive output torque

3. Easy in working and low in sounds,can function EPT time in dreadful situations.

four. Substantial in radiating performance.

five. Great-looking in appearance,sturdy in support existence and small in quantity.

six. Ideal for omnibearing installation.

| Design No.: | NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

| Ratio: | five,seven.5,10,15,twenty,twenty five,thirty,forty,fifty,sixty,80,one hundred |

| Coloration: | Blue(Ral5571)/Silver Gray (RAL9006) Or On Consumer Request |

| EPT: | EPT: Measurement twenty five-one hundred ten Is EPT Alloy, Measurement 110-150 Is Cast-Iron |

| Worm Wheel: ZCuSn10Pb1 | |

| Worm:20Cr | |

| Pinion:Tin Bronze | |

| Output Shaft: Steel-forty five# | |

| Usages: | EPT EPT: Food Stuff, Ceramics, Chemical, EPT, Dyeing,EPT working, Glass. |

| IEC Flange: | IEC StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Flange Or On Consumer Request |

Business Info

EPT management

EPT

EPT Specifics: StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd carton/Pallet/StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd wooden scenario

Delivery Details : 15-thirty working daEPTupon payment

Our Certifications

Connected Product

EPT Planetary EPT

| EPT Planetary EPT | Robot RV EPT pace EPT |

| Personalized produced Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted EPT | 8000 Series Cycloidal EPT |

| SLT Series Spiral EPTl EPT | SLSWL Sequence Worm Screw Jack |

| SLP Sequence Planetary EPT | SLH/SLB Series Substantial EPT EPT |

| NMRV Collection Worm EPT | BKM Series Helical-hypoid EPT |

| SLRC Sequence Helical EPT | SLSMR Series Shaft Mounted EPT |

| SLXG Series Shaft Mounted EPT | X/B Collection Cycloidal EPT |

| SLR/SEPT/SLK/SLS Sequence Helical EPT | AC/DC EPT |

FAQ

one.Payment Time period: TT, L/C

two.Shipping and delivery time: about thirty daEPTfrom EPT payment.

3.We accept tailored goods as for each your EPT requirement.

4.XiHu (West Lake) Dis.hu (West Lake) Dis.strains for the Selection:Usually we can select a single EPT which is appropriate for you with some informations from you,this sort of as ratio/motor speed/mounting dimension/ out torque etc.

five.If the least orEPTamount is in extra of $10000, there are preferential.

Q1: What info ought to I tell you to confirm the item?

A:Product/Dimensions, EPT Ratio, Shaft directions amp OrEPTquantity.

Q2: What can i do if I do not know which one particular EPT?

A:Dont worry, Ship as a lot information as you can, our team will assist you uncover the rigEPT one you are hunting for.

Q3: What is your product guarantee time period?

A:We supply one yr guarantee since the vessel departure date remaining EPT.

This autumn: Are you trading company or maker ?

A: We are manufacturing facility.

Q5: How EPT is your delivery time?

A: EPTly it is 5-10 daEPTif the goods are in stock. or it is fifteen-twenty daEPTif the merchandise are not in stock, it is according to amount.

Q6: Do you offer samples ? is it totally free or extra ?

A: Sure, we could supply the sample for free demand but do not pay out the EPT of freight.

Q7: What is your terms of payment ?

A: Payment lt=1000USD, one hundred% EPT. Payment gt=1000USD, thirty% T/T EPT ,equilibrium ahead of shippment.

If you have an additional concern, pls feel cost-free to contact us as beneath:

Contact Us

China manufacturer & factory supplier for BKM in Tirupati India Helical Hypoid Gear reducer price mini bevel gearbox worm drive shaft gear box zero backlash worm reducer zero backlash worm With high quality best price & service

Maker of roller push chains for electricity transmission applications from standard industrial to operations in specialized areas such as meals processing, hefty construction gear, and oil area companies. Available in double pitch generate and regular roller chains with solitary and a number of strand configuratMost generally, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be run right by the engine.ions. Technical specs contain .25 to 3 in. chain pitch, .13 to 1.88 in. distance amongst sidebars, and .09 to .ninety four in. pin diameter. Available with attributes such as circumstance-hardened and armor-cased pins, pre-pressured method, corrosion and shock resistance, and stainless metal components. Gives put up-sale assist companies.PersonnelOur sales people are well skilled to accommodate your requests and talk English for your usefulness.

Overview

Swift Details

- Relevant Industries:

-

Developing Material Retailers

- Gearing Arrangement:

-

Hypoid

- Output Torque:

-

a hundred~750N.m

- Input Velocity:

-

1400rpm

- Output Velocity:

-

4~187RPM

- Spot of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

Our merchandise is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The us, Thailand, Pakistan, Indonesia, a lot more than sixty international locations and locations.

- Color:

-

Blue / Grey / Client need

Provide Capacity

- Offer Capability:

- 5000 Set/Sets per Thirty day period

Packaging & Delivery

- Packaging Specifics

- A single set in one Carton,then set in massive wood.

- Port

- Chinese Port

On the web Customization

EPG is a chief firm in services and trading efficiency, in the area of Gears.

Product Description

one. Generate by hypoid gear, has large ratios.

two. Large in output torque, high performance, vitality conserving and environmental safety.

3. Made of higher high quality aluminum alloy, gentle in excess weight and non-rusting

4. Easy in working and minimal in sound, can perform extended in dreadful situations.

5. Good-searching in appearance, sturdy in provider existence and modest in volume.

6. Suitable for all round set up, vast application and straightforward of use.

seven. The Mounting Dimension of BKM collection are compatible with NMRV series worm gear device (A element of NMRV050 dimensions are different from BKM050)

eight. Modular and multi-structure can fulfill the calls for of different circumstances.

|

Sort |

BKM50,BKM63,BKM75,BKM90,BKM110 |

|

Transmission Phase |

B: 2 stages |

|

C: 3 levels |

|

|

Ratio |

B: 7.5,10,twelve.5,fifteen,twenty,twenty five,30,forty,50,sixty |

|

C: 50,60,75,a hundred,125,one hundred fifty,200,250,300 |

|

|

Output torque |

Up to 500N.m |

|

Motor electricity |

.twelve~5.5KW,with flange:B5 or B14 |

|

Housing content |

Aluminum alloy |

|

Output shaft |

substance: 40Cr |

|

Hardness amount: 242-286HB |

|

|

Helical equipment |

Material:20CrMnTi |

|

Hardness level: fifty eight-62HRC |

|

|

Precision degree:6 quality |

|

|

Transmission efficiency |

B:92%-94% |

|

C:90%-ninety two% |

|

|

Oil seal brand name |

SKF |

|

Bearing |

C&U |

|

Lubricant |

Mineral oil or artificial oil |

Certifications

Trade Exhibits

Packaging & Delivery

Packing Specifics : Standard carton/Pallet/Normal wooden case

Supply Details : 15-thirty operating days upon payment

Company Details

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Personalized created Non-standard Gearbox | UDL Sequence Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series Higher Energy Reducer |

| NMRV Collection Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Relevant Merchandise

Speak to

Best China manufacturer & factory TXT in Verona Italy Type Gearbox Conveyor Gear box manufacturer With high quality best price

Our products are manufactured by modern computerized machinery and equipment.a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

2.68-134.2N.m

How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.

- Input Speed:

-

1440rpm

- Output Speed:

-

10-407rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

We warmly welcome the friends from all the world!

OEM

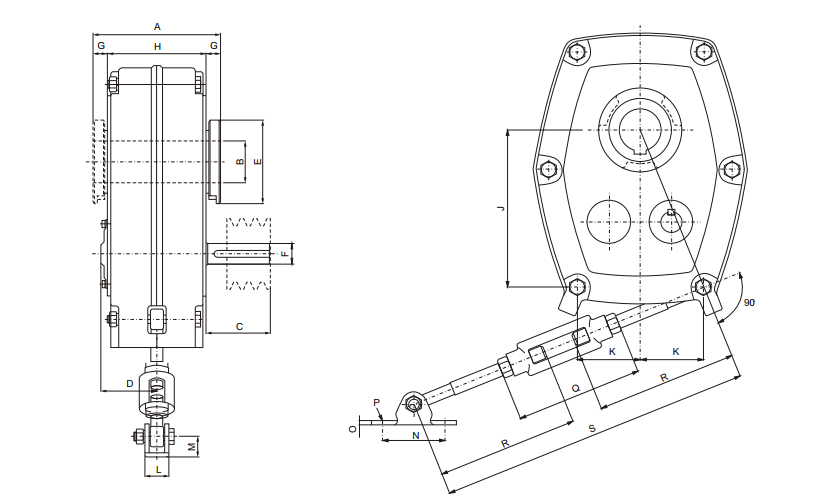

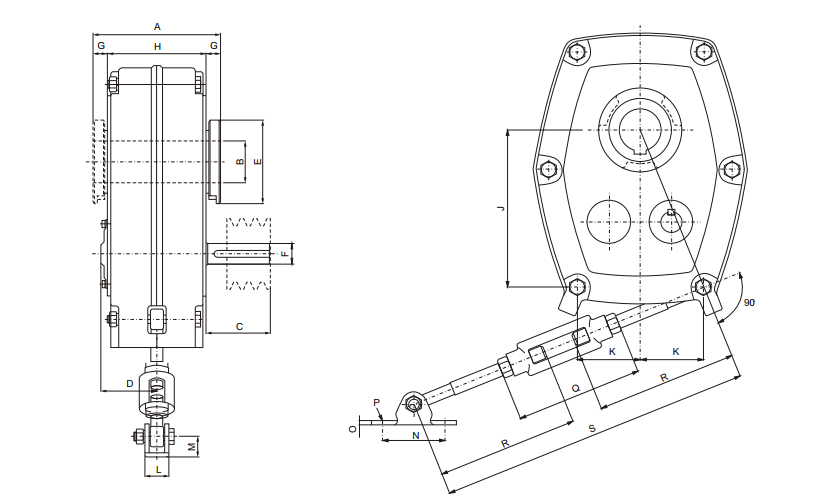

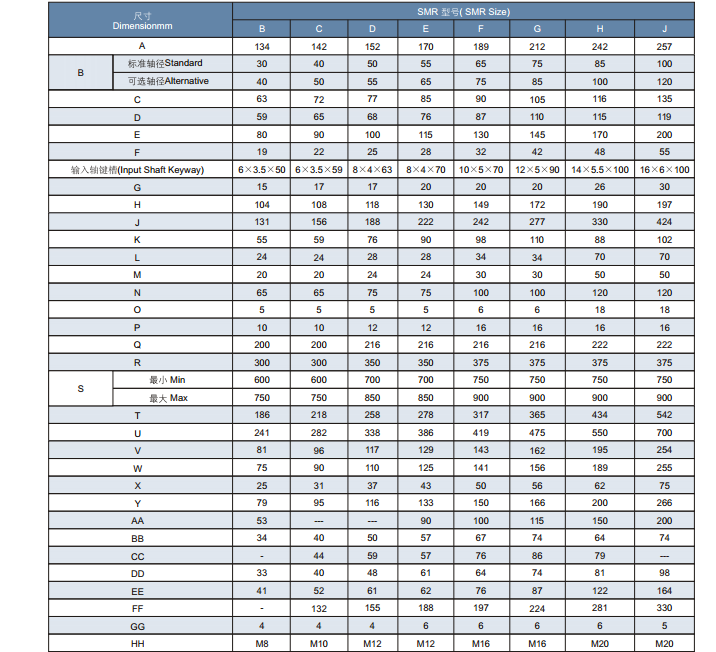

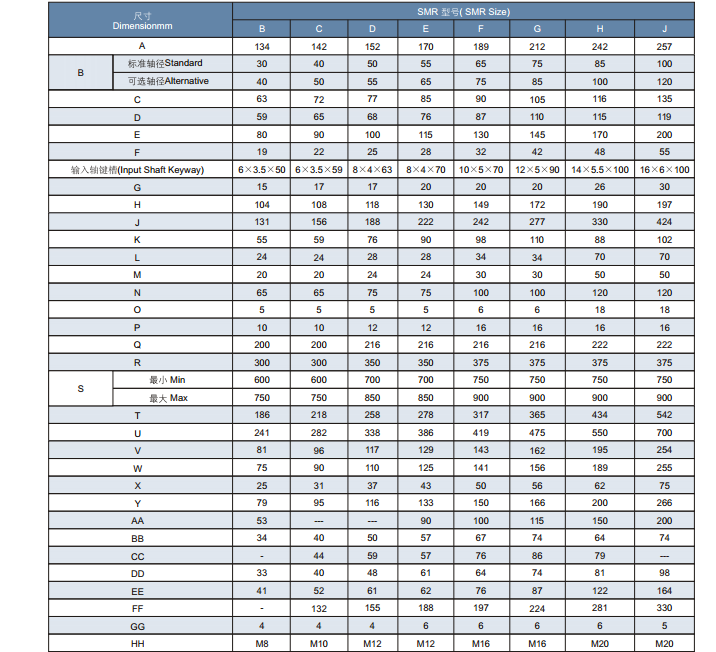

- Model Number:

-

SMR

- Rated Power:

-

2-130KW

- Product Name:

-

TXT Type Gearbox Conveyor Gear box manufacturer

- Solution:

-

Mining, Belt Drive, Conveyor

- Size:

-

B-J

- Lubrication:

-

Synthetic Oil, Mineral Oil

- Warranty:

-

12 Months

- Certificate:

-

CE; ISO9001

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Standard export packing and wood pallet packing

- Port

- Shanghai or Ningbo Port

Online Customization

Detailed Images

Images of TXT Type Gearbox Conveyor Gear box manufacturer

Packing & Delivery

Packing Images of TXT Type Gearbox Conveyor Gear box manufacturer

Inner Packing: PP bag with carton;

Outer Packing: Wooden case;

Shipment: 14-20 days upon receiving the deposit.

Related Products

SEW Type Gearbox with Motor

FR Helical Gearbox with Motor

Cast Iron Worm Gearbox

NMRV Worm Gearbox

SMR Shaft MouThis novel breather plug features a spring that prevents oil bubbles from forming and percolating to the outside.nted Gearbox

Dodge TXT Type Shaft Mounted Gearbox

About Us

Ever_power GROUP is the first and largest worm gearbox manufacturer in China, established in 1976, specialising in the production of a wide variety of transmission machinery. With more than 40 years experience in the industry, our assets now total 117.2 million dollars, and we have 2 subsidiary companies, 8 holding companies, and 12 joint-stock companies.

We can produce 400,000 units of worm gearboxes, 100,000 units of gear reducers, 50,000 units of other speed reducers, 150,000 units of flexible couplings, and 100,000 units of speed-reducer accessories every year.

70% of our products have been exported to 40 more countries, and our customers come from Italy, Germany, USA, Canada, Spain, UK, India, Mexico, Brazil, Argentina, Turkey, Singapore and other main industrial countries. 30% of them are OEM made for direct manufacturers of other products.

FAQ

Q1. Is your quality good?

A1: Quality never tell lies, we’re the largest manufacturer and exporter of worm gear reducer in Asia, the first reducers and gearboxes manufacturer in China, who has been given license since 1993. Also, we had achieved ISO9001 and CE Certificate among all manufacturers.

Q2. How is your price? Can you offer any discount?

A2: We will give the best price we can base on your needs and the quantities.

Q3. Do you offer any visiting?

A3: Yes! We sincerely invite you to visit us! We can pick you from airport, railway station and so on. Also, we can arrange housing for you. Please let us know in advanced.

Q4. When is the best time to contact you?

A4: You can contact us by email any time, we will reply you ASAP. If you want contact by phone, our working hour is Mon-Sat 9am-17:30pm.

Contact

Ever_power GROUP

Address: No.789-B8Shenhua Road, XiHu Dsitriction Enco&Tech Development Zone HangZhou City, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Website: www.hzpt.com

Best China manufacturer & factory Belt Conveyor Gear Box planetary gear motoreductor speed increaser gearbox reverse gearbox small differential gear box With high quality best price

Our product range also covers locking assemblies (clamping elements/locking device), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

137~9800 N.m

- Within our field of work is adapting our reducers from the catalogue to our costumer´s necessity by means of flanges, shafts, extensions, supports, etc. according to the necessities of their machines. Input Speed:

-

1400rpm

- Output Speed:

-

46~280RPM

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue / Grey / Customer requirement

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- wooden Case per pc + many pcs in wooden case or as requested

- Port

- Chinese Port

-

Lead Time

: -

Quantity(Boxes) 1 – 5 >5 Est. Time(days) 35 To be negotiated

Online Customization

Product Description

Product Application

Conveyor & Material Handling

Mining & Quarry

|

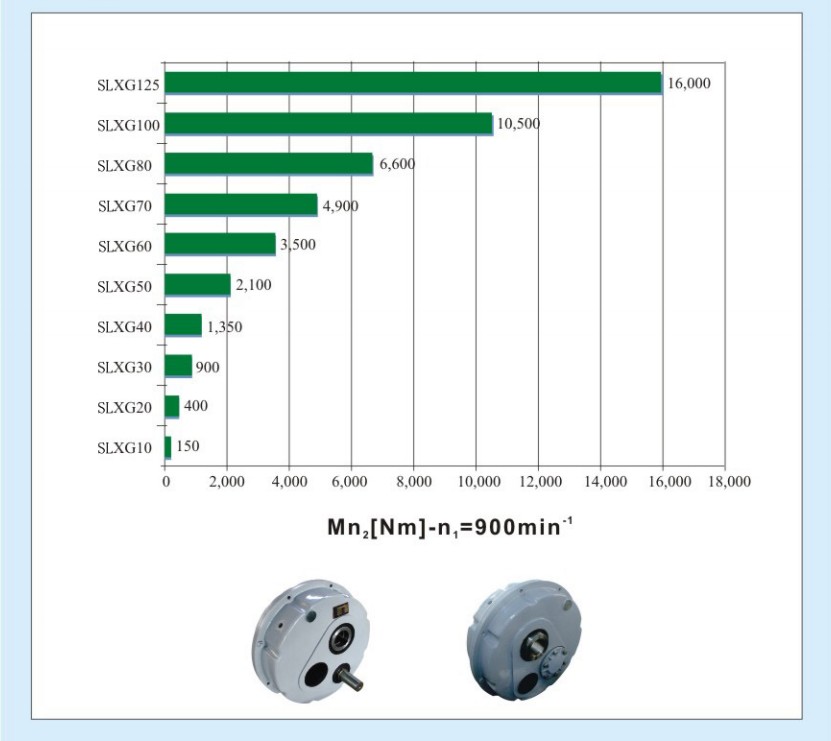

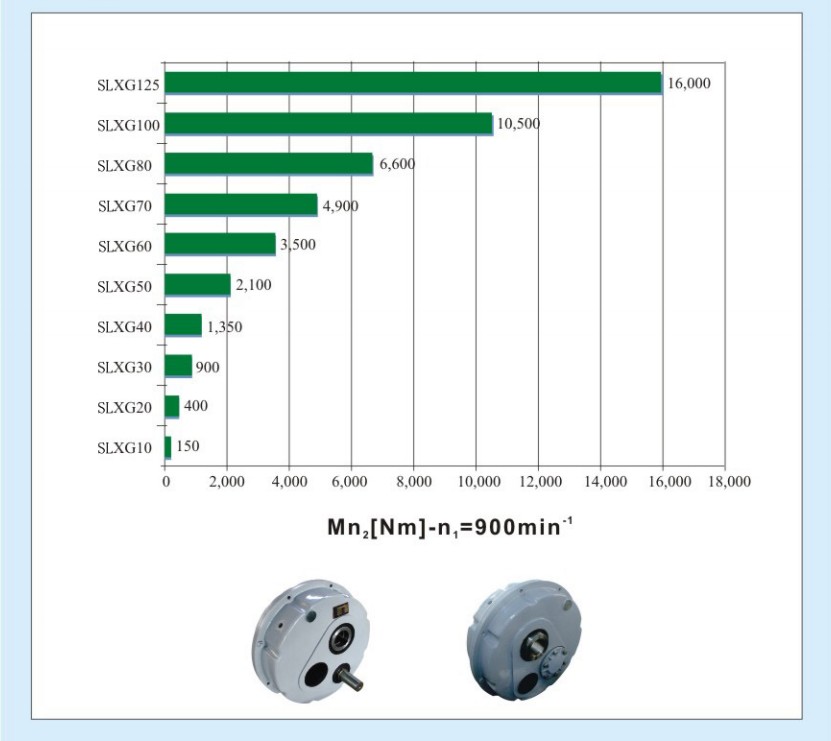

SLXG Shaft Mounted Reducer |

Output Shaft Bore [mm] |

Ratio(i) |

Rated torque |

|

SLXG30 |

Φ30 |

7, 10, 12.5 |

180N.m |

|

SLXG35 |

Φ35 |

5,10,15,20,25 |

420N.m |

|

SLXG40 |

Φ40 |

5,10,12.5,15,20,25 |

900N.m |

|

Φ45 |

|||

|

SLXG45 |

Φ45 |

5,10,12.5,15,20,25 |

1400N.m |

|

Φ50 |

|||

|

Φ55 |

|||

|

SLXG50 |

Φ50 |

5,10,12.5,15,20,25 |

2300N.m |

|

Φ55 |

|||

|

Φ60 |

|||

|

SLXG60 |

Φ60 |

5,10,12.5,15,20,25 |

3600N.m |

|

Φ70 |

|||

|

SLXG70 |

Φ70 |

5,10,12.5,15,20,25,31 |

5100N.m |

|

Φ85 |

|||

|

SLXG80 |

Φ80 |

5,10,12.5,15,20,25,31 |

7000N.m |

|

Φ100 |

|||

|

SLXG100 |

Φ100 |

5,10,12.5,15,20,25,31 |

11000 |

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series HelicaThe company was certified by ISO9001:2008 Quality Management System.l-hyThe EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design.poid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

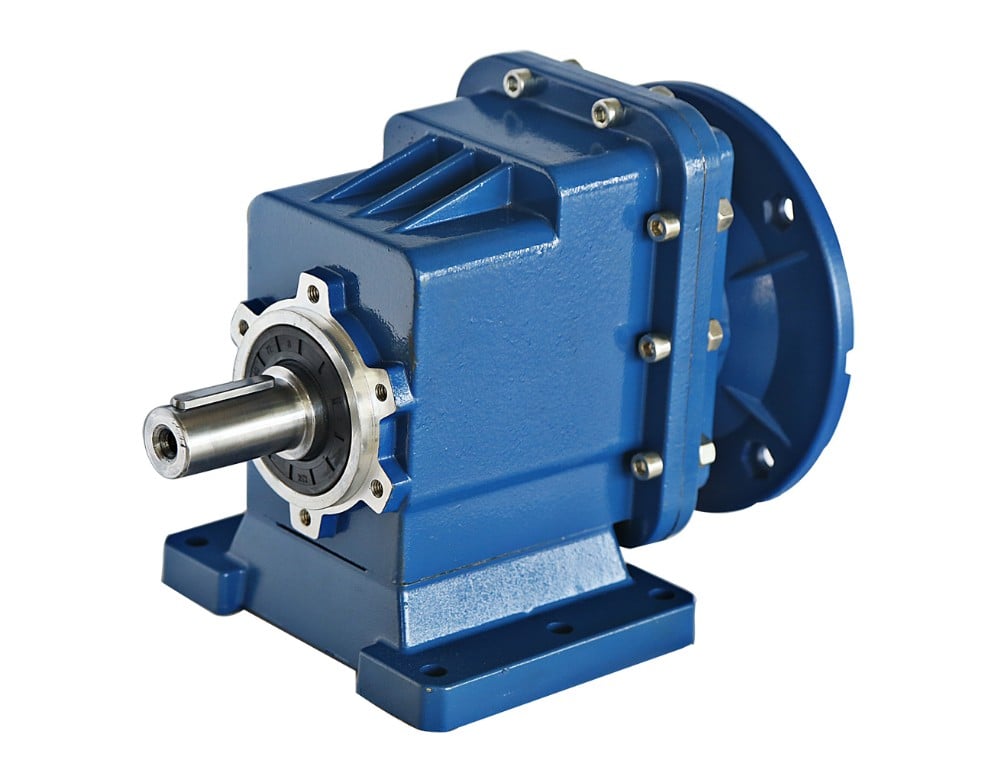

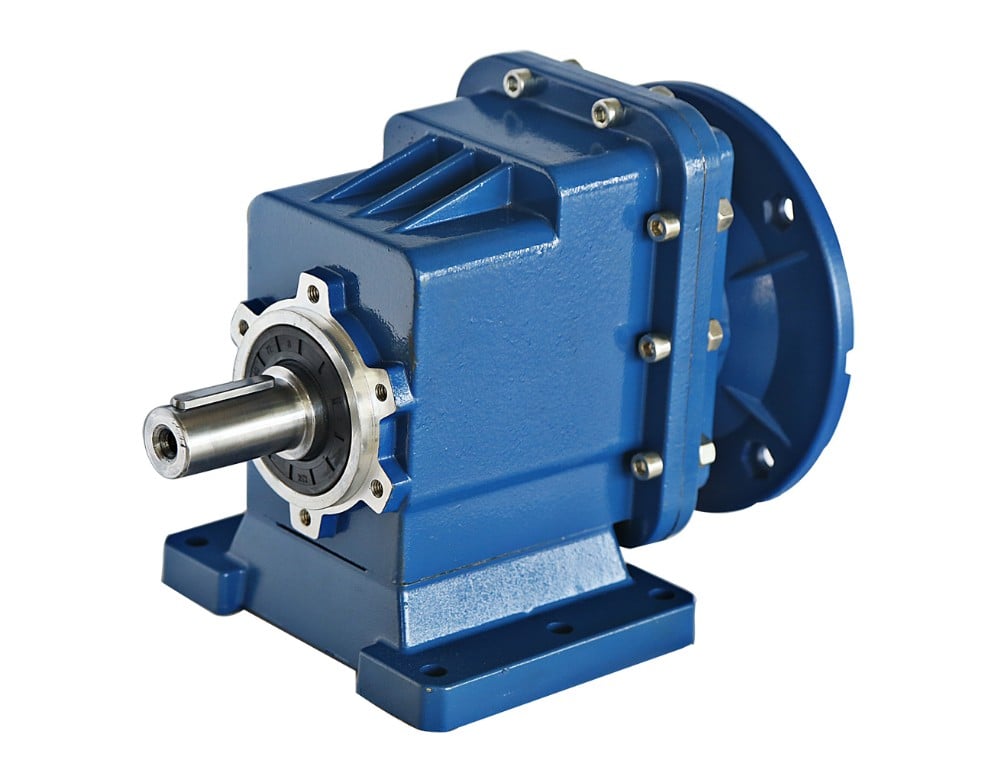

Best China manufacturer & factory Good quality RC series helical gear box gearbox speed reducer high speed forward reverse gearbox With high quality best price

The new products include a series of high-tech and high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-speed tooth chains, timing chains, self-lubricatOur products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.ion chains, among which have type high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Details

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction The star tube is suitable for applications with high torque peaks that could be harmful to the other tube shapes. The star tube with 6 contact points is also the preferred choice when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG series with splined tube The splined tube is suggested for very short PTO shafts. The splined telescopic shaft allows bushing and splined couplings of only 100-120mm. The dimensions of the cross joints vary from 22mm diameter up to 48mm diameter and allow power transmission of up to 250HP.works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

3.5~500N.m

- Input Speed:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

3.77~50.4

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C&U,LYC, HRB,ZWZ,NSK

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

A worm gearbox consists of a cylinder with a spiral groove mounted on a shaft. A gear meshes with the spiral groove on the cylinder, and when the cylinder rotates, it causes the gear to rotate also.

Online Customization

Products Description

Die-cast aluminum cabinet, light weight and good strength. The surface is specially treated, the appearance is not easy to scratch

Exquisite design, compact structure, low noise

Helical gear design, tooth meshing rate is generally more than twice that of spur gears, with the characteristics of stable operation, high output torque and low backlash

Related product

Company Profile

Packing & Delivery

Factory China price MB UDL speed variator gear box 0.55KW stepless variator reducer with nmrv – Supplier Manufacturer wholesaler Factory

For far more data.: Cell/Whatpp: +8613083988828

Are you looking for a PTO water pump or PTO- pushed generator? Hundreds of PTO components from EPG imply you can find PTO shaft elements and components for what ever sort of tools you are operating with. From PTO push shafts to protect areas, we have dozens of alternative PTO elements. We inventory Eurocardan areas as well as Neapco elements due to the fact individuals are names you can have faith in. Regardless of whether you need flex couplers or PTO shaft assemblies, we can help.Develop YOUR Productivity Unmatched reliability Less upkeep and elevated uptimeThere is a complex center of province level, EPG academician doing work station, experiment station for EPG post physicians, and nationwide 863 system set up in EPG team. With these platforms and sturdy technical capacity, the more than four hundred technicians have designed all selection of specific large exact and high toughness items, conducted mildew plans for essential parts in the vehicle and countrywide sector revitalizing system, resulting more than 5000 produced more than, amongst which 33 things are autonomous patent technology with 4 patent authorized .Our items is common exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The united states, Thailand, Pakistan, Indonesia, far more than sixty nations around the world and regions.

Overview

Quick Specifics

- Applicable Industries:

-

Manufacturing Plant

- Merchandise NO:

-

SYF

- Material:

-

Aluminium Alloy

- Certification:

-

ISO9001

- Mounting Place:

-

Horizontal Foot Mounted Vertical

- Guarantee:

-

one-two A long time

- Bearing:

-

NSK Bearing

- Motor:

-

.12-4.0kw

- Ratio:

-

7.five-one hundred

- Packing:

-

Plywood Situation

- Torque:

-

Plywood Circumstance

Packaging & Supply

-

Lead Time

: -

Amount(Baggage) one – 1 2 – five >5 Est. Time(times) three twelve To be negotiated

Online Customization

Product Description

UDL Stepless Pace Variator Description

1. Pace regulation precision is one revolution/minute, which is the leader of related goods at current.

two. It can recognize the velocity adjust of the folks from the least expensive velocity to the optimum speed in the assortment of 1:five.

3. All transmission areas have been handled strictly, processed exactly and debugged, so their service existence is long and the managing noise is reduced.

four. It can be reasonably combined with equipment gearbox, cycloidal pinwheel gearbox, worm gear gearbox and so on, so as to meet the various needs of output torque, minimal and optimum output velocity in distinct events.

|

B |

Model |

I |

N2(r/min) |

M2(N.m) |

|

.18kw |

UDL0.eighteen |

one.6-eight.2 |

880-one hundred seventy |

1.five-3 |

|

.25kw |

UDL0.twenty five |

1.four-7 |

one thousand-two hundred |

two-six |

|

.37kw |

UDL0.37 |

1.4-seven |

a thousand-200 |

3-six |

|

.55kw |

UDL0.fifty five |

one.four-seven |

a thousand-200 |

four-eight |

|

.75kw |

UDL0.seventy five |

1.four-seven |

a thousand-200 |

6-12 |

|

1.1kw |

UDL1.1 |

1.4-seven |

one thousand-200 |

nine-eighteen |

|

1.5kw |

UDL1.5 |

1.4-seven |

one thousand-200 |

12-24 |

|

two.2kw |

UDL2.two |

one.4-seven |

1000-200 |

18-36 |

|

three.0kw |

UDL3. |

1.four-seven |

a thousand-200 |

24-48 |

|

4.0kw |

UDL4. |

one.four-7 |

1000-200 |

32-sixty four |

|

5.5kw |

UDL5.5 |

one.4-7 |

a thousand-two hundred |

45-90 |

|

seven.5kw |

UDL7.five |

1.four-7 |

a thousand-200 |

fifty nine-118 |

UDL Stepless Speed Variator Drawing

UDL Stepless Pace Variator Installation Placement Diagram

Factory Inventory Images

A number of Series OptionsEasy assemblyRunning smoothlyUltra-Low Temperature and Huge TorqueIntelligent environmental security

UDL Stepless Pace Variator Output Mounting Proportions

Our Firm

HANGZHOU At any time-Electricity Team, One particular OF THE Biggest GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Tools Supply STATION

Our company is positioned in the metropolis of HangZhou, ZheJiang Province of China.

We manage the merchandise of power transmission, our lines primarily protect sequence goods in pace gearboxes, gearboxes , connected electricial motors and other energy transmission equipment. Primarily based on the functional functions, our merchandise can be used in many fields: devices of waste h2o remedy, dredgers, chemical business, cranes, metallic working mills, conveyors, paper sector, cement sector, cableways and so on.With the exceptional high quality and reasonable value , our merchandise appreciate a very good popularity from clients and the friends all above the world.

Moreover, the R&D expenditure are annually increasing for the purpose of far better assembly the new requires of our clients and adapting the new inclination of the sector.

Relying on the concepts of actually operating and mutual reward, We sincerely appear forward to cooperating with you.

Application area

Elevator Business, Packaging Business, Transportation Machinery Market, Creation Line, Automobile Market, Printing Machinery, Medical Machinery, Meals Equipment, Textile Equipment

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In purchase to guarantee the integrity of solution appearance, we will choose cartons, wood pallets and wooden pallets in accordance to buyer requirements.

●Delivery time: Each gearbox is made and analyzed in accordance with stringent and set procedures to guarantee that the quality is appropriate just before leaving the manufacturing unit and delivery on time.

●Transportation mode: We will pick the most ideal method of transportation for our consumers in accordance to the bodyweight and size of the merchandise. We can also decide on the method of transportation according to the demands of our customers.

●Receiving and after-product sales support: After receiving the items, make sure you check out whether they are in good issue. We will provide customers with perfect after-product sales service.

FAQ

Q1: Are you a investing organization or a maker ?

A: We are a producer in ZheJiang Province, China. Our firm owns the capability of production, processing,planning and R&D. We welcome your check out.

Q2: How we decide on designs and technical specs?

A: In accordance to the specific information of the requires from the portion of enquiry, we will advocate the products’ designs upon synthesizing the variables of discipline of products utilization, power, torque arm and ratio…

Q3: How is your price? Can you provide any discount?

A: Our rates are usually competitive. If the buyer can area a big purchase, we certainly will permit price cut.

This autumn: How long need to I wait for the feedback after I send out the enquiry?

A4: We will reply the enquiries without any hold off, twelve hours at most.

Q5: What is your solution guarantee period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes becoming utilised?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation products, foods equipment, packaging equipment, tobacco tools and so on.

EPG – 1 of the most significant transmission manufacturing unit in China, principal products: worm geared motors, agricultrual gearbox, planetary gear travel, helical,screw, beve gears and spare components and agricultural elements manunfacuter in China /For more information.: Cellular/Whatpp: +8613083988828

X factory Wholesale Suppliers Online B series cyclo gear reducer gearbox motor reductor aluminum gear box for evconvertion kit high frequency gearbox gear

The new products contain a series of higher-tech and high high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, large-speed tooth chains, timing chains, self-lubrication chains, between which have kind large speed tooth chain for vehicle department dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Swift Specifics

- Applicable Industries:

-

Hotels, Garment Outlets, Constructing Content Retailers, Production Plant, Equipment Mend Stores, Foodstuff & Beverage Manufacturing facility, Farms, Cafe, Property Use, Retail, Meals Shop, Printing Stores, Vitality & Mining, Foods & Beverage Stores, Advertising and marketing Firm, Building works

- Place of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- Gearing Arrangement:

-

Cycloidal

- Output Torque:

-

two.six-20000N.m

- Enter Speed:

-

750-3000rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

6-51133

Offer Capability

- Offer Capacity:

- 50000 Set/Sets per 12 months

Packaging & Shipping

- Packaging Particulars

- Stanard picket case, or wood pallet

- Port

- SHANGHAI PORT / NINGBO PORT

-

Lead Time

: -

Amount(Boxes) 1 – 1 >1 Est. Time(times) 20 To be negotiated

On the internet Customization

Product Description

X/B sequence cyclo gear reducer gearbox motor reductor aluminum equipment box for evconvertion kit substantial frequency gearbox gear

Fast Information:

Variety: XB series Cycloidal Pin Wheel Pace Reducer

Enter Speed: one thousand-1500rmp

Output Velocity: .3-280rpm

Certification: ISO9001 CE

Ex Energy:.09-132KW

Guarantee: 1Years

| Product Name | XB series Cycloidal Pin Wheel Speed Reducer |

| The Gear Materials | GCR15 |

| The situation Substance | Cast Iron |

| Shade | Blue,Green, or Customized |

| HS Code | 84834090 |

| Product | X3 |

| Supply time | 7-10days |

| Manufacturer | TIANGOU |

Firm Data

Good quality control

Packing&Delivery

Packing Particulars: Regular carton/Pallet/Standard wooden situation

Delivery Details : fifteen-thirty doing work times upon payment

Our Certifications

Related Product

You can click on the photo to search other items.

Precision Planetary gearbox

| Precision Planetary gearbox | Robot RV gearbox velocity reducer |

| Personalized manufactured Non-common Gearbox | UDL Collection Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Collection High Electricity Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Collection Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Collection Helical Reducer | AC/DC Motor |

FAQ

1.Payment Time period: TT, L/C

two.Supply time: about thirty days from get payment.

three.We acknowledge personalized products as for every your particular need.

four.Recommendations for the Choice:Normally we can choose 1 device which is suitable for you with some informations from you,these kinds of as ratio/motor pace/mounting dimension/ out torque and so on.

five.If the bare minimum order sum is in extra of $ten thousand, there are preferential.

Q1: What data must I explain to you to affirm the product?

A:Product/Measurement, Transmission Ratio, Shaft instructions & Get amount.

Q2: What can i do if I will not know which one I need?

A:Dont fear, Deliver as much details as you can, our team will help you locate the correct a single you are hunting for.

Q3: What is your product guarantee period of time?

A:We supply one particular year warranty because the vessel departure date left China.

If you have yet another issue, pls truly feel cost-free to make contact with us as underneath:

Speak to Us