Product Description

We are professional best bevel gearbox hollow shaft 1:1, bevel gears drive hollow shaft speed increaser manufacturers and suppliers from China. All bevel gearbox hollow shaft 1:1, bevel gears drive hollow shaft speed increaser will be tested and inspection reports before products shipment.

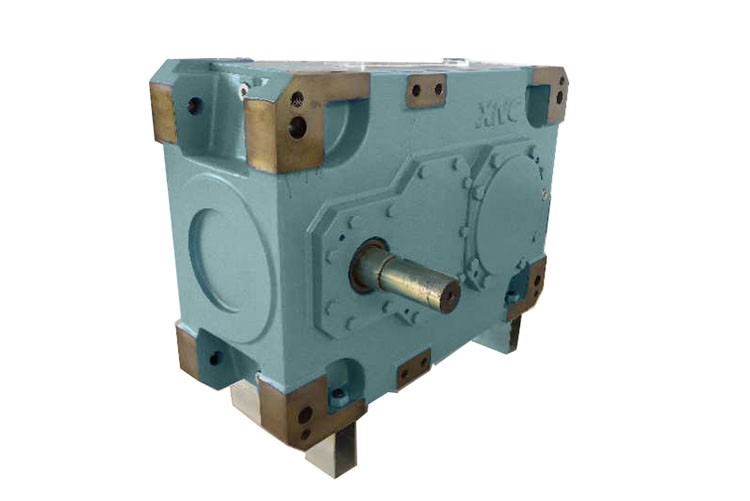

JTP Series Cubic Bevel Gearbox

CZPT JTP series cubic bevel gearbox is also known as cubic right angle miter gearbox, cubic 90 degree bevel gearbox, cubic miter bevel gear box, or cubic spiral bevel gear reducers. JTP series cubic bevel gearbox is a right-angle shaft type gear box of spiral bevel gears for general applications with high transmission capacity, high performance and high efficiency. 1:1, 1.5:1, 2:1, 3:1, 4:1 and 5:1 gear ratios as standard. 2 way(one input 1 output), 3 way(one input 2 output, or 2 input 1 output), 4 way(two input 2 output) drive shafts as standard. CZPT shaft as standard, customize hollow shaft or motor flange to bolt an IEC motor flange. Maximum torque 1299N.m. Maximum input and output speed 1450RPM. There are 8 models: JTP65 mini cubic bevel gearbox, JTP90 cubic bevel gearbox, JTP110 cubic bevel gearbox, JTP140 cubic bevel gearbox, JTP170 cubic bevel gearbox, JTP210 cubic bevel gearbox, JTP240 cubic bevel gearbox and JTP280 cubic bevel gearbox.

| JTP65 Mini Cubic Bevel Gearbox 1. bevel gear ratio 1:1 2. CZPT drive shafts diameter12mm 3. CZPT input and output shaft shafts 4. 2 way, 3 way, 4 way gearbox 5. input power maximum 1.8Kw 6. drive torque maximum 13.5Nm 7. maximum input 156567X3, registered Capital 500000CNY) is a leading manufacturer and supplier in China for screw jacks (mechanical actuators), bevel gearboxes, lifting systems, linear actuators, gearmotors and speed reducers, and others linear motion and power transmission products. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CZPT Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications. Website 1: http://screw-jacks Website 2: /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do manufacturers ensure the compatibility of drive shafts with different equipment?Manufacturers employ various strategies and processes to ensure the compatibility of drive shafts with different equipment. Compatibility refers to the ability of a drive shaft to effectively integrate and function within a specific piece of equipment or machinery. Manufacturers take into account several factors to ensure compatibility, including dimensional requirements, torque capacity, operating conditions, and specific application needs. Here’s a detailed explanation of how manufacturers ensure the compatibility of drive shafts: 1. Application Analysis: Manufacturers begin by conducting a thorough analysis of the intended application and equipment requirements. This analysis involves understanding the specific torque and speed demands, operating conditions (such as temperature, vibration levels, and environmental factors), and any unique characteristics or constraints of the equipment. By gaining a comprehensive understanding of the application, manufacturers can tailor the design and specifications of the drive shaft to ensure compatibility. 2. Customization and Design: Manufacturers often offer customization options to adapt drive shafts to different equipment. This customization involves tailoring the dimensions, materials, joint configurations, and other parameters to match the specific requirements of the equipment. By working closely with the equipment manufacturer or end-user, manufacturers can design drive shafts that align with the equipment’s mechanical interfaces, mounting points, available space, and other constraints. Customization ensures that the drive shaft fits seamlessly into the equipment, promoting compatibility and optimal performance. 3. Torque and Power Capacity: Drive shaft manufacturers carefully determine the torque and power capacity of their products to ensure compatibility with different equipment. They consider factors such as the maximum torque requirements of the equipment, the expected operating conditions, and the safety margins necessary to withstand transient loads. By engineering drive shafts with appropriate torque ratings and power capacities, manufacturers ensure that the shaft can handle the demands of the equipment without experiencing premature failure or performance issues. 4. Material Selection: Manufacturers choose materials for drive shafts based on the specific needs of different equipment. Factors such as torque capacity, operating temperature, corrosion resistance, and weight requirements influence material selection. Drive shafts may be made from various materials, including steel, aluminum alloys, or specialized composites, to provide the necessary strength, durability, and performance characteristics. The selected materials ensure compatibility with the equipment’s operating conditions, load requirements, and other environmental factors. 5. Joint Configurations: Drive shafts incorporate joint configurations, such as universal joints (U-joints) or constant velocity (CV) joints, to accommodate different equipment needs. Manufacturers select and design the appropriate joint configuration based on factors such as operating angles, misalignment tolerances, and the desired level of smooth power transmission. The choice of joint configuration ensures that the drive shaft can effectively transmit power and accommodate the range of motion required by the equipment, promoting compatibility and reliable operation. 6. Quality Control and Testing: Manufacturers implement stringent quality control processes and testing procedures to verify the compatibility of drive shafts with different equipment. These processes involve conducting dimensional inspections, material testing, torque and stress analysis, and performance testing under simulated operating conditions. By subjecting drive shafts to rigorous quality control measures, manufacturers can ensure that they meet the required specifications and performance criteria, guaranteeing compatibility with the intended equipment. 7. Compliance with Standards: Manufacturers ensure that their drive shafts comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, provides assurance of quality, safety, and compatibility. Adhering to these standards helps manufacturers meet the expectations and requirements of equipment manufacturers and end-users, ensuring that the drive shafts are compatible and can be seamlessly integrated into different equipment. 8. Collaboration and Feedback: Manufacturers often collaborate closely with equipment manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft design and manufacturing processes. This collaborative approach ensures that the drive shafts are compatible with the intended equipment and meet the expectations of the end-users. By actively seeking input and feedback, manufacturers can continuously improve their products’ compatibility and performance. In summary, manufacturers ensure the compatibility of drive shafts with different equipment through a combination of application analysis, customization, torque and power capacity considerations, material selection, joint configurations, quality control and testing, compliance with standards, and collaboration with equipment manufacturers and end-users. These efforts enable manufacturers to design and produce drive shafts that seamlessly integrate with various equipment, ensuring optimal performance, reliability, and compatibility in different applications.

How do drive shafts enhance the performance of automobiles and trucks?Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks: 1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently. 2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance. 3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling. 4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability. 5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance. 6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance. 7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics. 8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness. 9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime. 10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance. In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

Are there variations in drive shaft designs for different types of machinery?Yes, there are variations in drive shaft designs to cater to the specific requirements of different types of machinery. The design of a drive shaft is influenced by factors such as the application, power transmission needs, space limitations, operating conditions, and the type of driven components. Here’s an explanation of how drive shaft designs can vary for different types of machinery: 1. Automotive Applications: In the automotive industry, drive shaft designs can vary depending on the vehicle’s configuration. Rear-wheel-drive vehicles typically use a single-piece or two-piece drive shaft, which connects the transmission or transfer case to the rear differential. Front-wheel-drive vehicles often use a different design, employing a drive shaft that combines with the constant velocity (CV) joints to transmit power to the front wheels. All-wheel-drive vehicles may have multiple drive shafts to distribute power to all wheels. The length, diameter, material, and joint types can differ based on the vehicle’s layout and torque requirements. 2. Industrial Machinery: Drive shaft designs for industrial machinery depend on the specific application and power transmission requirements. In manufacturing machinery, such as conveyors, presses, and rotating equipment, drive shafts are designed to transfer power efficiently within the machine. They may incorporate flexible joints or use a splined or keyed connection to accommodate misalignment or allow for easy disassembly. The dimensions, materials, and reinforcement of the drive shaft are selected based on the torque, speed, and operating conditions of the machinery. 3. Agriculture and Farming: Agricultural machinery, such as tractors, combines, and harvesters, often requires drive shafts that can handle high torque loads and varying operating angles. These drive shafts are designed to transmit power from the engine to attachments and implements, such as mowers, balers, tillers, and harvesters. They may incorporate telescopic sections to accommodate adjustable lengths, flexible joints to compensate for misalignment during operation, and protective shielding to prevent entanglement with crops or debris. 4. Construction and Heavy Equipment: Construction and heavy equipment, including excavators, loaders, bulldozers, and cranes, require robust drive shaft designs capable of transmitting power in demanding conditions. These drive shafts often have larger diameters and thicker walls to handle high torque loads. They may incorporate universal joints or CV joints to accommodate operating angles and absorb shocks and vibrations. Drive shafts in this category may also have additional reinforcements to withstand the harsh environments and heavy-duty applications associated with construction and excavation. 5. Marine and Maritime Applications: Drive shaft designs for marine applications are specifically engineered to withstand the corrosive effects of seawater and the high torque loads encountered in marine propulsion systems. Marine drive shafts are typically made from stainless steel or other corrosion-resistant materials. They may incorporate flexible couplings or dampening devices to reduce vibration and mitigate the effects of misalignment. The design of marine drive shafts also considers factors such as shaft length, diameter, and support bearings to ensure reliable power transmission in marine vessels. 6. Mining and Extraction Equipment: In the mining industry, drive shafts are used in heavy machinery and equipment such as mining trucks, excavators, and drilling rigs. These drive shafts need to withstand extremely high torque loads and harsh operating conditions. Drive shaft designs for mining applications often feature larger diameters, thicker walls, and specialized materials such as alloy steel or composite materials. They may incorporate universal joints or CV joints to handle operating angles, and they are designed to be resistant to abrasion and wear. These examples highlight the variations in drive shaft designs for different types of machinery. The design considerations take into account factors such as power requirements, operating conditions, space constraints, alignment needs, and the specific demands of the machinery or industry. By tailoring the drive shaft design to the unique requirements of each application, optimal power transmission efficiency and reliability can be achieved.

China manufacturer & factory supplier for T in Barcelona-Puerto La Cruz Venezuela series 90 degree bevel gearbox With high quality best price & service

ISO 9001, ISO/TS 16949 and AS9100 certified. Producer of normal and personalized roller chains for use in a vast selection of programs. Roller chains are obtainable in solitary-pitch, double-pitch and precision versions. Meets or exceed ANSI specifications.Additionally, all our manufacturing methods are in compliance with ISO9002 expectations for a specialized provider of a complete variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Specifics

In our firm we are informed of the importance of the users’ protection. That is why our PTO’s are developed in accordance to authorized restrictions and European directives and bear the CE sign. A crucial issue for safety assurance is the accession in the products’ advancement stage. By all signifies, the users’ knowledge about the appropriate use of a PTO push shaft is essential. This implies, that each and every users’ obligation is to read through and follow the security directions.

Provide Capacity

Packaging & Delivery

On the web Customization

Product Description

Product ApplicationT series bevel gearbox is standardized with several versions. The deceleration ratio is 1:1, 1.5:1, 2:1, 2.5:1 and 3:1, which are all actual transmission ratios.Good and negative operation, low speed or higher velocity transmission smooth, minimal sounds, tiny vibration bearing capability.

Primary Functionsone.T series spiral bevel equipment steering box, standardized, multi assortment, pace ratio is all actual transmission ratio. The typical efficie EPG is specialised in design and style, producer and income of agricultural equipment and farm implements, which has an impartial import and export legal rights. ncy was 98%.

Our Provider

(1) With excellent top quality and Reasonable cost

Packing & Shipping and delivery

Associated Items

Products Identify with hyperlinkninety one.8% Reaction Price

Merchandise Title with website linkninety one.8% Reaction Rate

Goods Title with url91.8% Reaction Rate

China manufacturer & factory supplier for BKM in Tirupati India Helical Hypoid Gear reducer price mini bevel gearbox worm drive shaft gear box zero backlash worm reducer zero backlash worm With high quality best price & service

Maker of roller push chains for electricity transmission applications from standard industrial to operations in specialized areas such as meals processing, hefty construction gear, and oil area companies. Available in double pitch generate and regular roller chains with solitary and a number of strand configuratMost generally, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be run right by the engine.ions. Technical specs contain .25 to 3 in. chain pitch, .13 to 1.88 in. distance amongst sidebars, and .09 to .ninety four in. pin diameter. Available with attributes such as circumstance-hardened and armor-cased pins, pre-pressured method, corrosion and shock resistance, and stainless metal components. Gives put up-sale assist companies.PersonnelOur sales people are well skilled to accommodate your requests and talk English for your usefulness.

Overview

Swift Details

Our merchandise is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The us, Thailand, Pakistan, Indonesia, a lot more than sixty international locations and locations.

Provide Capacity

Packaging & Delivery

On the web CustomizationEPG is a chief firm in services and trading efficiency, in the area of Gears.

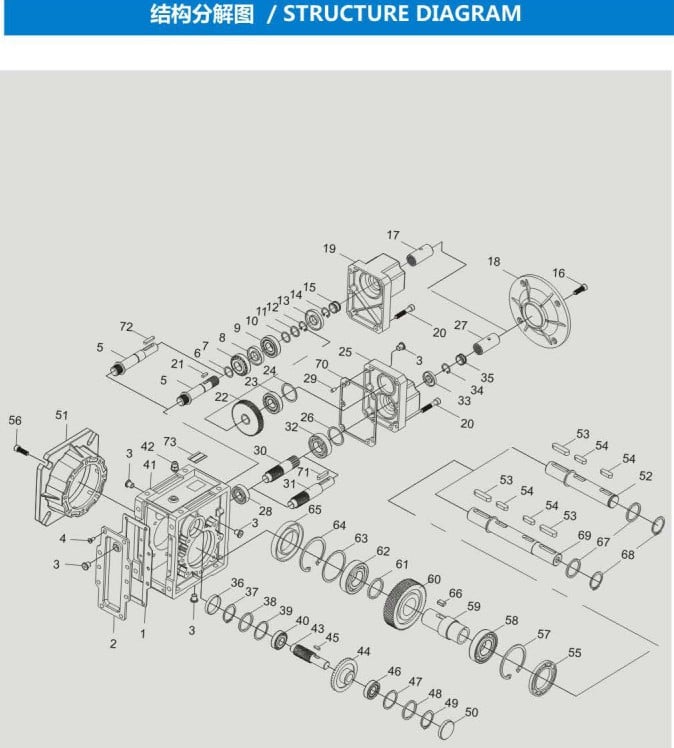

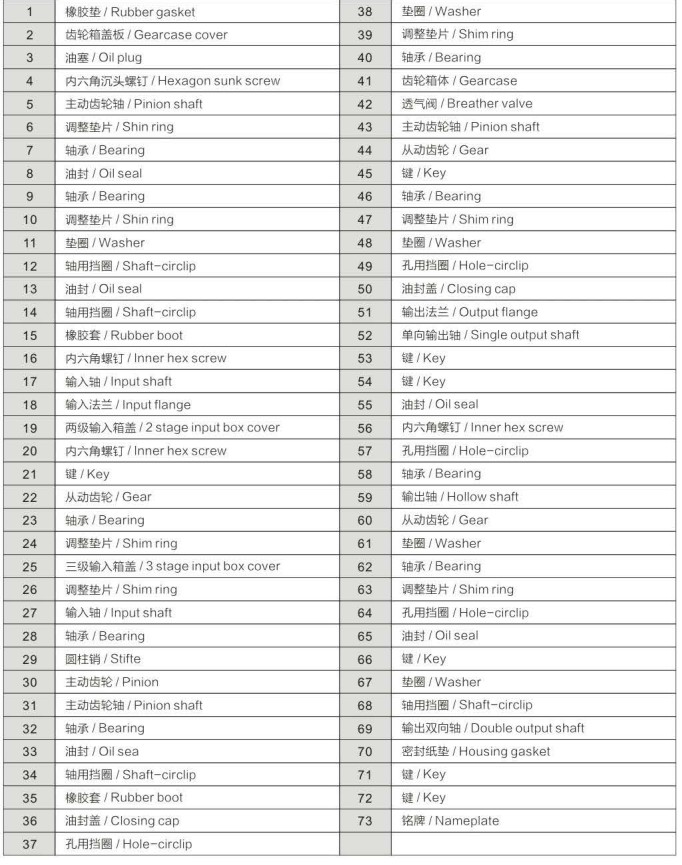

Product Description

one. Generate by hypoid gear, has large ratios. two. Large in output torque, high performance, vitality conserving and environmental safety. 3. Made of higher high quality aluminum alloy, gentle in excess weight and non-rusting 4. Easy in working and minimal in sound, can perform extended in dreadful situations. 5. Good-searching in appearance, sturdy in provider existence and modest in volume. 6. Suitable for all round set up, vast application and straightforward of use. seven. The Mounting Dimension of BKM collection are compatible with NMRV series worm gear device (A element of NMRV050 dimensions are different from BKM050) eight. Modular and multi-structure can fulfill the calls for of different circumstances.

Certifications

Trade Exhibits

Packaging & Delivery Packing Specifics : Standard carton/Pallet/Normal wooden case Supply Details : 15-thirty operating days upon payment

Company Details

other series product

Relevant Merchandise

Speak to

china China best quality China best supplier supplier right angle spiral bevel gearbox prices for lifting cranes

EPG will usually adhere to it business spirit of becoming sensible, modern, successful and exceptional to make the leading worldwide transmission travel.

Overview

Fast Information

Source Ability

Packaging & Delivery

On the internet Customization

Product Description

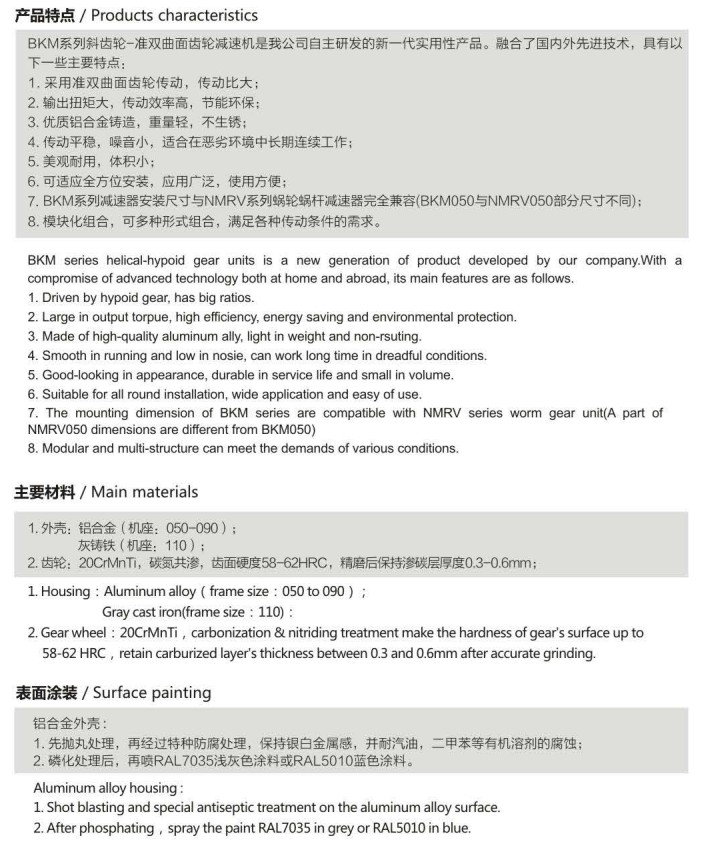

H B Series Industrial GearBox

Ever-Power Machinery —— Tianqi Model Industrial gearbox makers/Equipment Box Transmission Chinese electric powered motor speed reducer is widely utilised in mining machinery, chemical sector,metal metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food market and so on. Principal Series Product: R collection helical gear reducer, K collection spiral bevel gear reducer, NGW, P sequence planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone equipment reducer, cycloid reducer, and so forth. In the meantime, map sample processing organization can be carried out.

Specification

H B Series Gearbox Reducer: (please speak to us for much more kinds & product)

Mounting Diamensions: Design assortment for washing machine Equipment Box Transmission: Carefully employing the perfect reduction ratio. Reduction ratio = servo motor pace / reducer output shaft pace Torque calculation: Torque calculation is really critical for the life of reducer, and pay attention to regardless of whether the maximum torque price (TP) of acceleration exceeds the maximum load torque of the reducer. The relevant electrical power is usually the relevant electricity of the servo models on the marketplace, the applicability of the reducer is quite higher, the working coefficient can be taken care of above 1.2, but the choice can also be primarily based on their possess demands to decide.H B series common industrial gear box reducer.Industrial Right Angle Transmission Gearbox price tag.Gearbox Manufacturer helical equipment style gearbox with average price.HB Bevel helical gearbox for drinking water treatment.Chinese Gearbox Manufacturer H B Sequence Industrial Equipment Box Reducer.Higher Torque H B Helical gearbox for hauling winches.H B Sequence Helical gearbox for bucket elevators.H B Helical washing machine gear box price tag for hauling winches and conveyors.H B Helical Large rpm Reduction Gearbox cost for conveyors one:40 ratio.High precision H B sequence industrial heavy obligation gear gearbox velocity reducer.correct angle spiral bevel gearbox rates for lifting cranes.

Attribute:

Company Data Started in 1995, HangZhou Ever-Energy Power machinery Co.,Ltd has 22 years of reducer creation experience and reliability. The firm has professional engineer team, advanced technology production and skilled personnel, with located in HangZhou of ZheJiang province which has solid industrial foundation and produced transportation. Chinese Speed Reducer is a mechanical transmission in several fields of the national economy. The product groups coated by the sector consist of all kinds of gear reducer, planetary gear reducer and worm gearbox, as effectively as numerous particular transmission devices such as speed escalating device, speed management Products, which includes a variety of sorts of adaptable transmission products, such as compound transmission. Goods and providers in the discipline of metallurgy, nonferrous metals, coal, constructing components, ships, water conservancy, electrical power, construction equipment and petrochemical industries. In all fields of national economic climate and countrywide protection sector, gearbox goods have a wide assortment of programs. Foods mild sector, electric powered equipment, construction equipment, metallurgy machinery, cement equipment, environmental defense equipment, digital appliances, street design equipment, h2o conservancy equipment, chemical equipment, mining equipment, conveyor equipment, creating resources machinery, rubber machinery, petroleum machinery and other industries have strong desire of Reducer merchandise.Industrial Proper Angle Transmission Gearbox price tag.Gearbox Company helical equipment design gearbox with average value.HB Bevel helical gearbox for h2o therapy.Chinese Gearbox Manufacturer H B Sequence Industrial Gear Box Reducer.High Torque H B Helical gearbox for hauling winches.H B Sequence Helical gearbox for bucket elevators.washing machine H B Helical equipment box price for hauling winches and conveyors.H B Helical Higher rpm Reduction Gearbox price tag for conveyors one:40 ratio.3: one ratio gearbox.one:thirty ratio gearbox.Substantial precision H B series industrial large duty gear gearbox pace reducer.appropriate angle spiral bevel gearbox prices for lifting cranes. Packaging & Shipping and delivery

FAQ 1.Q:Are you the manufacturing facility or investing firm? A:We are the skilled Factory with 22 many years of experience.

2.Q:Can you personalize according to our requirements? A:Yes, we can layout nonstandard items according to customer’s drawing and sample.

3.Q:How long is the shipping date? A:ten-20 operating times.

4.Q:In which is your factory? A:We are in HangZhou of ZheJiang Province, you can get listed here by large pace practice or fly to Jinan. Welcome to check out us!

K China series helical bevel gear motor right angle gearbox speed reducer drive power transmission gear reduction boxes – Supplier Manufacturer wholesaler Factory

For more information.: Cellular/Whatpp: +8613083988828 Maintaining in thoughts that great support is the key to cooperating with consumers, we attempt to fulfill substantial good quality expectations, provide competitive costs and guarantee prompt shipping and delivery. The company covering 88,000 square meters, has sophisticated gear and powerful specialized energy, this kind of as the numerical management equipment instruments and machining facilities, CAD/CAM system, industrial robot and many others.

Overview

Fast Particulars

Supply Potential

Packaging & Supply

On-line Customization

Specification

K sequence helical bevel gear motor right angle gearbox pace gearbox is one kind of Helical Bevel sort gearbox , High-stainless forged iron situation . ,it is designed dependent on modularization , which carry numerous difference varieties of combinations ,mounting types ,and composition designs .The detail classification of ratio can meet up with various of functioning condition .Large Transmission performance ,Minimal power usage, exceptional overall performance . The difficult tooth surface area equipment use the higher high quality alloy steel , the approach of carburizing and quenching, grinding ,which give it follow figures : Secure transmission , minimal noise and temperature ,large loading ,extended working life. which extensively use for industry products of metallurgy ,Creating Materials , Chemical , Mining , Oil, Transportation , Papermaking , Sugar generating , engineering Devices ,and so forth 1) Output pace: .six~1,028r/min 2) Output torque: up to 21700N.m

Certifications

trade display

Packing

Company information

High quality Management

Get in touch with us

EPG – one of the most significant transmission factory in China, main goods: worm geared motors, agricultrual gearbox, planetary gear generate, helical,screw, beve gears and spare elements and agricultural elements manunfacuter in ChinaFor a lot more info.: Cellular/Whatpp: +8613083988828

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||