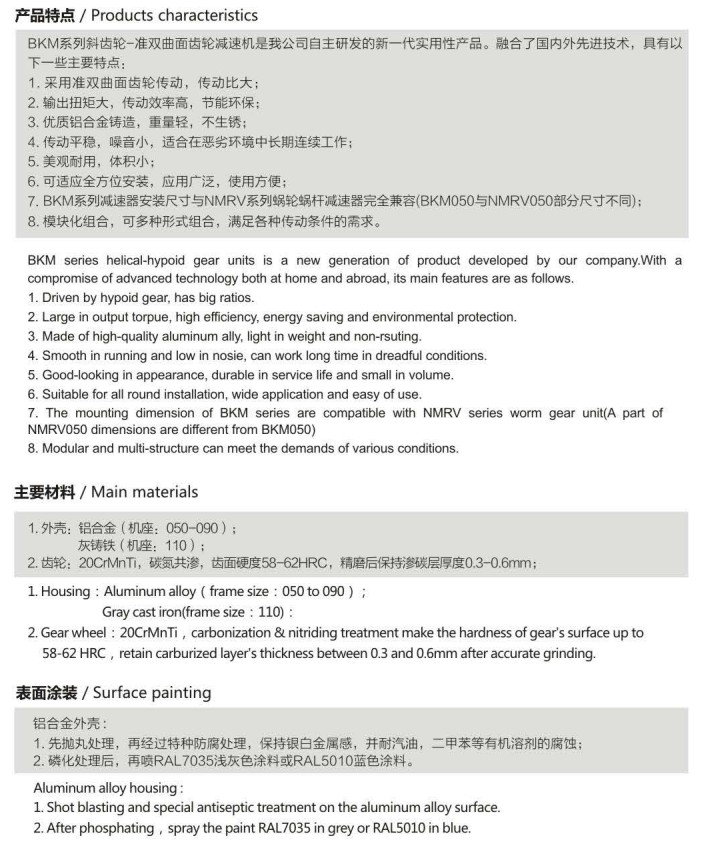

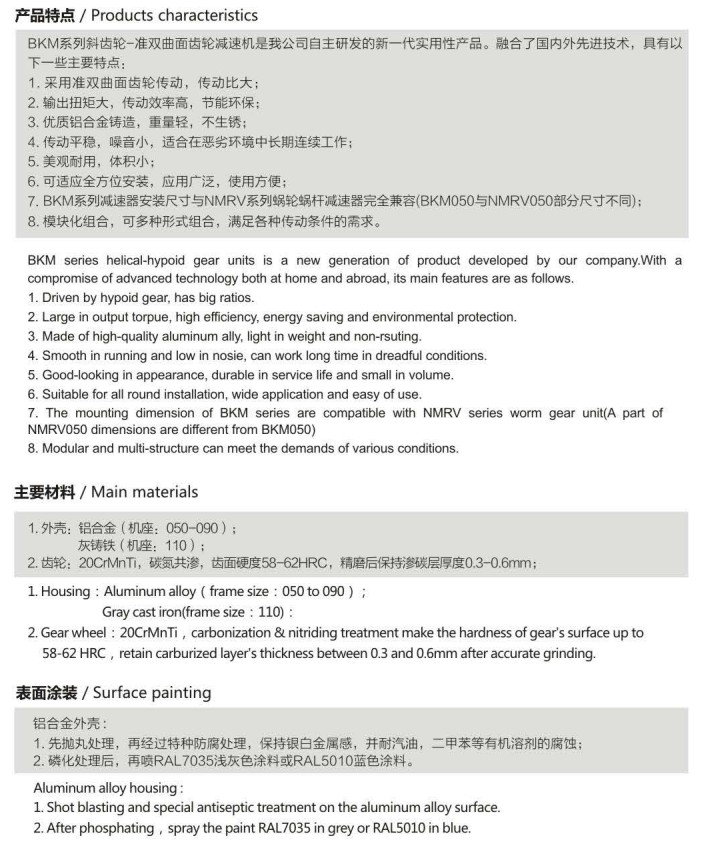

Product Description

Product Parameters

| Product Name | Gearbox Output Shaft Assembly |

| Model NO. | HW25716XA AMT |

| Certification | ISO9001 |

| Brake System Parts | Brake Control |

| Transmission System Parts | Gearbox |

| Steering System Parts | Steering Transmission Device |

| Measurement | 24*17*14cm |

| Transport Package | Exporting Standard |

| Specification | 18/24/32/38/41c*L530/535mm |

| Origin | China |

| Production Capacity | 10000 PCS/Month |

| Application | Shacman, Sinotruk, FAW,etc |

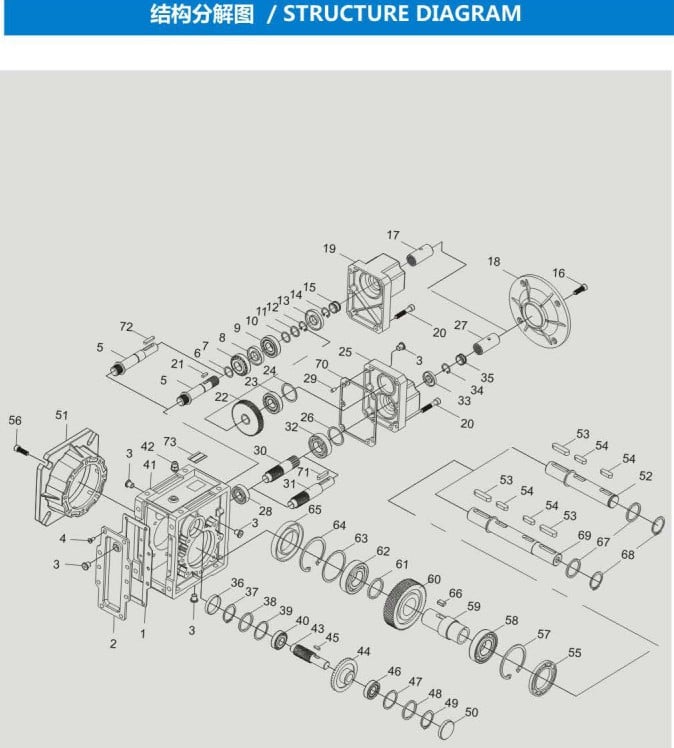

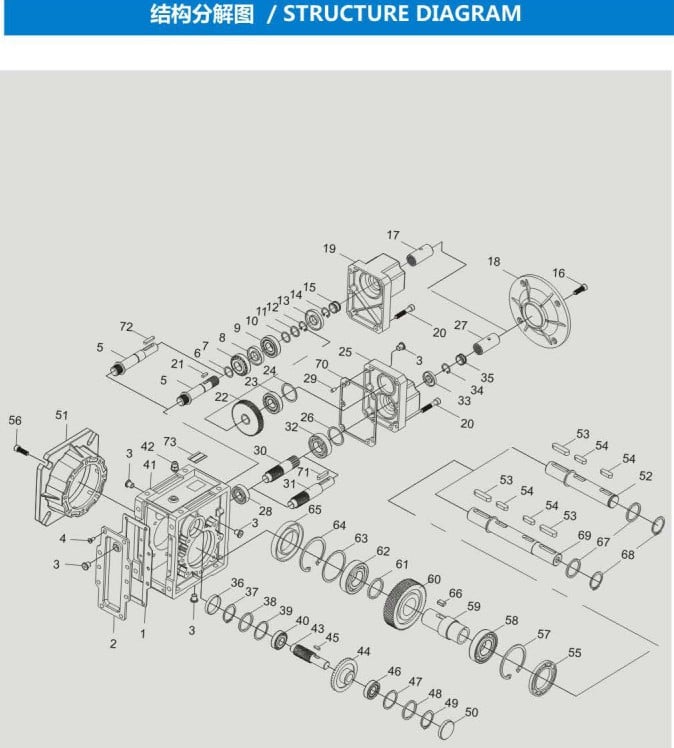

Detailed Photos

Our Advantages

1. We have been committed to the heavy truck accessories industry for more than 10 years. The company’s professional team can quickly match any products you need, saving you purchasing time;

2. Excellent product quality is the foundation of our company and the cornerstone on which our company has always relied for survival;

3.Our company has formed a complete supply chain, which can process customer orders within 2 hours, arrange production plans and ship goods as soon as possible;

4. Our company has complete after-sales guarantee, and excellent after-sales service is the main factor for us to reach follow-up cooperation with customers.

Company Profile

Certifications

Packaging & Shipping

Customer Visit

FAQ

1. About the condition of the truck:

Each product will have a test report.We guarantee that the product is in good condition.

2. About delivery:

Divided into flat frame container, bulk carrier, roll-on – roll ship

3.MOQ:

1 group

4. About OEM:

Welcome, you can send your own designed LOGO, we can open a new mold for you to print or emboss any LOGO.

5. Terms of payment:

For sample orders, you can use telegraphic transfer, sight L/C, Western Union, Paypal, MoneyGram, Alipay or credit card.

6. About delivery time:

The exact delivery time depends on the item you order and the quantity.

7. About Us:

We have a professional vehicle renewal team, 1 for every truck Test report.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Good |

|---|---|

| Warranty: | 12 Months |

| Type: | Gearbox |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What maintenance practices are crucial for prolonging the lifespan of drive shafts?

To prolong the lifespan of drive shafts and ensure their optimal performance, several maintenance practices are crucial. Regular maintenance helps identify and address potential issues before they escalate, reduces wear and tear, and ensures the drive shaft operates smoothly and efficiently. Here are some essential maintenance practices for prolonging the lifespan of drive shafts:

1. Regular Inspection:

Performing regular inspections is vital for detecting any signs of wear, damage, or misalignment. Inspect the drive shaft visually, looking for cracks, dents, or any signs of excessive wear on the shaft itself and its associated components such as joints, yokes, and splines. Check for any signs of lubrication leaks or contamination. Additionally, inspect the fasteners and mounting points to ensure they are secure. Early detection of any issues allows for timely repairs or replacements, preventing further damage to the drive shaft.

2. Lubrication:

Proper lubrication is essential for the smooth operation and longevity of drive shafts. Lubricate the joints, such as universal joints or constant velocity joints, as recommended by the manufacturer. Lubrication reduces friction, minimizes wear, and helps dissipate heat generated during operation. Use the appropriate lubricant specified for the specific drive shaft and application, considering factors such as temperature, load, and operating conditions. Regularly check the lubrication levels and replenish as necessary to ensure optimal performance and prevent premature failure.

3. Balancing and Alignment:

Maintaining proper balancing and alignment is crucial for the lifespan of drive shafts. Imbalances or misalignments can lead to vibrations, accelerated wear, and potential failure. If vibrations or unusual noises are detected during operation, it is important to address them promptly. Perform balancing procedures as necessary, including dynamic balancing, to ensure even weight distribution along the drive shaft. Additionally, verify that the drive shaft is correctly aligned with the engine or power source and the driven components. Misalignment can cause excessive stress on the drive shaft, leading to premature failure.

4. Protective Coatings:

Applying protective coatings can help prolong the lifespan of drive shafts, particularly in applications exposed to harsh environments or corrosive substances. Consider using coatings such as zinc plating, powder coating, or specialized corrosion-resistant coatings to enhance the drive shaft’s resistance to corrosion, rust, and chemical damage. Regularly inspect the coating for any signs of degradation or damage, and reapply or repair as necessary to maintain the protective barrier.

5. Torque and Fastener Checks:

Ensure that the drive shaft’s fasteners, such as bolts, nuts, or clamps, are properly torqued and secured according to the manufacturer’s specifications. Loose or improperly tightened fasteners can lead to excessive vibrations, misalignment, or even detachment of the drive shaft. Periodically check and retighten the fasteners as recommended or after any maintenance or repair procedures. Additionally, monitor the torque levels during operation to ensure they remain within the specified range, as excessive torque can strain the drive shaft and lead to premature failure.

6. Environmental Protection:

Protecting the drive shaft from environmental factors can significantly extend its lifespan. In applications exposed to extreme temperatures, moisture, chemicals, or abrasive substances, take appropriate measures to shield the drive shaft. This may include using protective covers, seals, or guards to prevent contaminants from entering and causing damage. Regular cleaning of the drive shaft, especially in dirty or corrosive environments, can also help remove debris and prevent buildup that could compromise its performance and longevity.

7. Manufacturer Guidelines:

Follow the manufacturer’s guidelines and recommendations for maintenance practices specific to the drive shaft model and application. The manufacturer’s instructions may include specific intervals for inspections, lubrication, balancing, or other maintenance tasks. Adhering to these guidelines ensures that the drive shaft is properly maintained and serviced, maximizing its lifespan and minimizing the risk of unexpected failures.

By implementing these maintenance practices, drive shafts can operate reliably, maintain efficient power transmission, and have an extended service life, ultimately reducing downtime and ensuring optimal performance in various applications.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

Can you explain the different types of drive shafts and their specific applications?

Drive shafts come in various types, each designed to suit specific applications and requirements. The choice of drive shaft depends on factors such as the type of vehicle or equipment, power transmission needs, space limitations, and operating conditions. Here’s an explanation of the different types of drive shafts and their specific applications:

1. Solid Shaft:

A solid shaft, also known as a one-piece or solid-steel drive shaft, is a single, uninterrupted shaft that runs from the engine or power source to the driven components. It is a simple and robust design used in many applications. Solid shafts are commonly found in rear-wheel-drive vehicles, where they transmit power from the transmission to the rear axle. They are also used in industrial machinery, such as pumps, generators, and conveyors, where a straight and rigid power transmission is required.

2. Tubular Shaft:

Tubular shafts, also called hollow shafts, are drive shafts with a cylindrical tube-like structure. They are constructed with a hollow core and are typically lighter than solid shafts. Tubular shafts offer benefits such as reduced weight, improved torsional stiffness, and better damping of vibrations. They find applications in various vehicles, including cars, trucks, and motorcycles, as well as in industrial equipment and machinery. Tubular drive shafts are commonly used in front-wheel-drive vehicles, where they connect the transmission to the front wheels.

3. Constant Velocity (CV) Shaft:

Constant Velocity (CV) shafts are specifically designed to handle angular movement and maintain a constant velocity between the engine/transmission and the driven components. They incorporate CV joints at both ends, which allow flexibility and compensation for changes in angle. CV shafts are commonly used in front-wheel-drive and all-wheel-drive vehicles, as well as in off-road vehicles and certain heavy machinery. The CV joints enable smooth power transmission even when the wheels are turned or the suspension moves, reducing vibrations and improving overall performance.

4. Slip Joint Shaft:

Slip joint shafts, also known as telescopic shafts, consist of two or more tubular sections that can slide in and out of each other. This design allows for length adjustment, accommodating changes in distance between the engine/transmission and the driven components. Slip joint shafts are commonly used in vehicles with long wheelbases or adjustable suspension systems, such as some trucks, buses, and recreational vehicles. By providing flexibility in length, slip joint shafts ensure a constant power transfer, even when the vehicle chassis experiences movement or changes in suspension geometry.

5. Double Cardan Shaft:

A double Cardan shaft, also referred to as a double universal joint shaft, is a type of drive shaft that incorporates two universal joints. This configuration helps to reduce vibrations and minimize the operating angles of the joints, resulting in smoother power transmission. Double Cardan shafts are commonly used in heavy-duty applications, such as trucks, off-road vehicles, and agricultural machinery. They are particularly suitable for applications with high torque requirements and large operating angles, providing enhanced durability and performance.

6. Composite Shaft:

Composite shafts are made from composite materials such as carbon fiber or fiberglass, offering advantages such as reduced weight, improved strength, and resistance to corrosion. Composite drive shafts are increasingly being used in high-performance vehicles, sports cars, and racing applications, where weight reduction and enhanced power-to-weight ratio are critical. The composite construction allows for precise tuning of stiffness and damping characteristics, resulting in improved vehicle dynamics and drivetrain efficiency.

7. PTO Shaft:

Power Take-Off (PTO) shafts are specialized drive shafts used in agricultural machinery and certain industrial equipment. They are designed to transfer power from the engine or power source to various attachments, such as mowers, balers, or pumps. PTO shafts typically have a splined connection at one end to connect to the power source and a universal joint at the other end to accommodate angular movement. They are characterized by their ability to transmit high torque levels and their compatibility with a range of driven implements.

8. Marine Shaft:

Marine shafts, also known as propeller shafts or tail shafts, are specifically designed for marine vessels. They transmit power from the engine to the propeller, enabling propulsion. Marine shafts are usually long and operate in a harsh environment, exposed to water, corrosion, and high torque loads. They are typically made of stainless steel or other corrosion-resistant materials and are designed to withstand the challenging conditions encountered in marine applications.

It’simportant to note that the specific applications of drive shafts may vary depending on the vehicle or equipment manufacturer, as well as the specific design and engineering requirements. The examples provided above highlight common applications for each type of drive shaft, but there may be additional variations and specialized designs based on specific industry needs and technological advancements.

editor by CX 2024-02-07

China wholesaler Large Helical Gear Shaft for Feed Machinery Big Gearbox drive shaft ends

Product Description

Our Feature

1) In-house capability: OEM service as per customers’ requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer’s requirement

5) Just-in-time delivery capability

Primary Competitive Advantages

1. Professional bull helical gear manufacturer

2. Experience in Cooperate with Fortune 500 Companies

3. Professional Engineering Capability

4. Stable Quality

5. Reasonable Price

6. Small Orders Accepted

7. Continuous Improvements

8. High Product Performance

9. Prompt Delivery

10. Professional Service

Our Main Product

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. Gear Wheel

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Gear

9. Spline Shaft

Company Profile

1.21 years experience in high quality Gear Shaft’s production, sales and R&D

2. Our product, the Gear Shaft is certificated by ISO9001: 2008 and ISO14001: 2004.

3. CZPT has more than 50 patents in high quality Gear Shaft manufacturing and R&D fieles.

4. CZPT products are exported to America, Europe.

Q&A:

Service and quality information:

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don’t have drawing, what can you do for me?

A: If you don’t have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there’s any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| AGMA/ DIN Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Custom Made Parts Examples:

| Material: | 17CrNiMo6 |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Gear Shaft |

| Appearance Shape: | Round |

| Customization: |

Available

| Customized Request |

|---|

How to tell if your driveshaft needs replacing

What is the cause of the unbalanced drive shaft? Unstable U-joint? Your car may make clicking noises while driving. If you can hear it from both sides, it might be time to hand it over to the mechanic. If you’re not sure, read on to learn more. Fortunately, there are many ways to tell if your driveshaft needs replacing.

unbalanced

An unbalanced driveshaft can be the source of strange noises and vibrations in your vehicle. To fix this problem, you should contact a professional. You can try a number of things to fix it, including welding and adjusting the weight. The following are the most common methods. In addition to the methods above, you can use standardized weights to balance the driveshaft. These standardized weights are attached to the shaft by welders.

An unbalanced drive shaft typically produces lateral vibrations per revolution. This type of vibration is usually caused by a damaged shaft, missing counterweights, or a foreign object stuck on the drive shaft. On the other hand, torsional vibrations occur twice per revolution, and they are caused by shaft phase shifts. Finally, critical speed vibration occurs when the RPM of the drive shaft exceeds its rated capacity. If you suspect a driveshaft problem, check the following:

Manually adjusting the imbalance of a drive shaft is not the easiest task. To avoid the difficulty of manual balancing, you can choose to use standardized weights. These weights are fixed on the outer circumference of the drive shaft. The operator can manually position the weight on the shaft with special tools, or use a robot. However, manual balancers have many disadvantages.

unstable

When the angular velocity of the output shaft is not constant, it is unstable. The angular velocity of the output shaft is 0.004 at ph = 29.5 and 1.9 at t = 1.9. The angular velocity of the intermediate shaft is not a problem. But when it’s unstable, the torque applied to it is too much for the machine. It might be a good idea to check the tension on the shaft.

An unstable drive shaft can cause a lot of noise and mechanical vibration. It can lead to premature shaft fatigue failure. CZPT studies the effect of shaft vibration on the rotor bearing system. They investigated the effect of flex coupling misalignment on the vibration of the rotor bearing system. They assume that the vibrational response has two components: x and y. However, this approach has limited application in many situations.

Experimental results show that the presence of cracks in the output shaft may mask the unbalanced excitation characteristics. For example, the presence of superharmonic peaks on the spectrum is characteristic of cracks. The presence of cracks in the output shaft masks unbalanced excitation characteristics that cannot be detected in the transient response of the input shaft. Figure 8 shows that the frequency of the rotor increases at critical speed and decreases as the shaft passes the natural frequency.

Unreliable

If you’re having trouble driving your car, chances are you’ve run into an unreliable driveshaft. This type of drivetrain can cause the wheels to stick or not turn at all, and also limit the overall control of the car. Whatever the reason, these issues should be resolved as soon as possible. Here are some symptoms to look for when diagnosing a driveshaft fault. Let’s take a closer look.

The first symptom you may notice is an unreliable drive shaft. You may feel vibrations, or hear noises under the vehicle. Depending on the cause, it could be a broken joint or a broken shaft. The good news is that driveshaft repairs are generally relatively inexpensive and take less time than a complete drivetrain replacement. If you’re not sure what to do, CZPT has a guide to replacing the U-connector.

One of the most common signs of an unreliable driveshaft is clanging and vibration. These sounds can be caused by worn bushings, loose U-joints, or damaged center bearings. This can cause severe vibration and noise. You can also feel these vibrations through the steering wheel or the floor. An unreliable driveshaft is a symptom of a bigger problem.

Unreliable U-joints

A car with an unreliable U-joint on the drive shaft can be dangerous. A bad u-joint can prevent the vehicle from driving properly and may even cause you trouble. Unreliable u-joints are cheap to replace and you should try getting parts from quality manufacturers. Unreliable U-joints can cause the car to vibrate in the chassis or gear lever. This is a sure sign that your car has been neglected in maintenance.

Replacing a U-joint is not a complicated task, but it requires special tools and a lot of elbow grease. If you don’t have the right tools, or you’re unfamiliar with mechanical terminology, it’s best to seek the help of a mechanic. A professional mechanic will be able to accurately assess the problem and propose an appropriate solution. But if you don’t feel confident enough, you can replace your own U-connector by following a few simple steps.

To ensure the vehicle’s driveshaft is not damaged, check the U-joint for wear and lubrication. If the U-joint is worn, the metal parts are likely to rub against each other, causing wear. The sooner a problem is diagnosed, the faster it can be resolved. Also, the longer you wait, the more you lose on repairs.

damaged drive shaft

The driveshaft is the part of the vehicle that connects the wheels. If the driveshaft is damaged, the wheels may stop turning and the vehicle may slow down or stop moving completely. It bears the weight of the car itself as well as the load on the road. So even a slight bend or break in the drive shaft can have dire consequences. Even a piece of loose metal can become a lethal missile if dropped from a vehicle.

If you hear a screeching noise or growl from your vehicle when shifting gears, your driveshaft may be damaged. When this happens, damage to the u-joint and excessive slack in the drive shaft can result. These conditions can further damage the drivetrain, including the front half. You should replace the driveshaft as soon as you notice any symptoms. After replacing the driveshaft, you can start looking for signs of wear.

A knocking sound is a sign of damage to the drive shaft. If you hear this sound while driving, it may be due to worn couplings, damaged propshaft bearings, or damaged U-joints. In some cases, the knocking noise can even be caused by a damaged U-joint. When this happens, you may need to replace the entire driveshaft, requiring a new one.

Maintenance fees

The cost of repairing a driveshaft varies widely, depending on the type and cause of the problem. A new driveshaft costs between $300 and $1,300, including labor. Repairing a damaged driveshaft can cost anywhere from $200 to $300, depending on the time required and the type of parts required. Symptoms of a damaged driveshaft include unresponsiveness, vibration, chassis noise and a stationary car.

The first thing to consider when estimating the cost of repairing a driveshaft is the type of vehicle you have. Some vehicles have more than one, and the parts used to make them may not be compatible with other cars. Even if the same car has two driveshafts, the damaged ones will cost more. Fortunately, many auto repair shops offer free quotes to repair damaged driveshafts, but be aware that such work can be complicated and expensive.

editor by CX 2023-04-21

China Custom 12V 24V Mini Gearbox Right Angle Gear Motors Worm Shaft Option Threaded Shaft Worm Gear Motor near me shop

itemvalueBrand NameKSTONEMOTORModel NumberKS-40W31ZYCertificationsCE, ROHSContinuous Current(A)0.2~5 AEfficiencyIE 3Torque3~50 kg.cmVoltage6V 12V 24VRated Speed10~160 rpmPower7~20 W Specification Related Products Company Profile HangZhoug Kstone Motor is a professional micro gear box manufacturer. The gear box included spur gear box, Planetary gear box, worm gears, Wheelchair motor. Kstone Motor has always been an excellent DC Gear Motors manufacturer.The motors are widely used for Automotive, Home appliances, Personal care, Powertools, Electric Actuator Motor Drive Gearbox Ball Valve DN15 3way Upscale Custom Made Actuator Plastic Valve Body Brass Water Junzhou Industry, and Intelligent products which provide healthy and convenient ways in life. Kstone Motor has a large number of production equipment, test equipment, gear processing equipment imported from Japan and Switzerland. Buyer Comments Packing & Delivery 1. 40PCS/Carton 2 Gross weight : 33 KG/Carton FAQ Q: Are you trading company or manufacturer?A: We are factory.Q: How to order?A: send us inquiry → receive our quotation → negotiate details → confirm the sample → Customized Timing Belt Pulley 8M Pulley S3M5M Transmission Synchronous Belt H Steel L Aluminum Xl Timing Belt Pulley sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperationQ: How about Sample order?A: Sample is available for you. please contact us for details.Q: Which shipping way is available?A: DHL, FedEx, By Sea are available. The other shipping ways are also available, please contact us if you need ship by the other shipping way. Q: How long is the deliver, NMRV series worm gearbox for tiller worm gearbox 47rpm output 25mm size 50 2 ac gearbox motor producing and shipping?A: Deliver time depends on the quantity you order. usually it takes 15-25 working days.Q: How to confirm the payment?A: We accept payment by T/T, PayPal, the other payment ways also could be accepted, Please contact us before you pay by the other payment ways. Also 50% deposit is available, the balance money should be paid before shipping.Q: What is your terms of payment?A: Payment=20000USD, Weili 114 remote control car 144001 metal upgrade accessories gear + drive shaft + gear middle drive shaft kit 50% T/T in advance ,balance before shipment.If you have another question, please feel free to contact us.

What Are Worm Gears and Worm Shafts?

If you’re looking for a fishing reel with a worm gear system, you’ve probably come across the term ‘worm gear’. But what are worm gears and worm shafts? And what are the advantages and disadvantages of worm gears? Let’s take a closer look! Read on to learn more about worm gears and shafts! Then you’ll be well on your way to purchasing a reel with a worm gear system.

worm gear reducers

Worm shaft reducers have a number of advantages over conventional gear reduction mechanisms. First, they’re highly efficient. While single stage worm reducers have a maximum reduction ratio of about five to sixty, hypoid gears can typically go up to a maximum of one hundred and twenty times. A worm shaft reducer is only as efficient as the gearing it utilizes. This article will discuss some of the advantages of using a hypoid gear set, and how it can benefit your business.

To assemble a worm shaft reducer, first remove the flange from the motor. Then, remove the output bearing carrier and output gear assembly. Lastly, install the intermediate worm assembly through the bore opposite to the attachment housing. Once installed, you should carefully remove the bearing carrier and the gear assembly from the motor. Don’t forget to remove the oil seal from the housing and motor flange. During this process, you must use a small hammer to tap around the face of the plug near the outside diameter of the housing.

Worm gears are often used in reversing prevention systems. The backlash of a worm gear can increase with wear. However, a duplex worm gear was designed to address this problem. This type of gear requires a smaller backlash but is still highly precise. It uses different leads for the opposing tooth face, which continuously alters its tooth thickness. Worm gears can also be adjusted axially.

worm gears

There are a couple of different types of lubricants that are used in worm gears. The first, polyalkylene glycols, are used in cases where high temperature is not a concern. This type of lubricant does not contain any waxes, which makes it an excellent choice in low-temperature applications. However, these lubricants are not compatible with mineral oils or some types of paints and seals. Worm gears typically feature a steel worm and a brass wheel. The brass wheel is much easier to remodel than steel and is generally modeled as a sacrificial component.

The worm gear is most effective when it is used in small and compact applications. Worm gears can greatly increase torque or reduce speed, and they are often used where space is an issue. Worm gears are among the smoothest and quietest gear systems on the market, and their meshing effectiveness is excellent. However, the worm gear requires high-quality manufacturing to perform at its highest levels. If you’re considering a worm gear for a project, it’s important to make sure that you find a manufacturer with a long and high quality reputation.

The pitch diameters of both worm and pinion gears must match. The two worm cylinders in a worm wheel have the same pitch diameter. The worm wheel shaft has two pitch cylinders and two threads. They are similar in pitch diameter, but have different advancing angles. A self-locking worm gear, also known as a wormwheel, is usually self-locking. Moreover, self-locking worm gears are easy to install.

worm shafts

The deflection of worm shafts varies with toothing parameters. In addition to toothing length, worm gear size and pressure angle, worm gear size and number of helical threads are all influencing factors. These variations are modeled in the standard ISO/TS 14521 reference gear. This table shows the variations in each parameter. The ID indicates the worm shaft’s center distance. In addition, a new calculation method is presented for determining the equivalent bending diameter of the worm.

The deflection of worm shafts is investigated using a four-stage process. First, the finite element method is used to compute the deflection of a worm shaft. Then, the worm shaft is experimentally tested, comparing the results with the corresponding simulations. The final stage of the simulation is to consider the toothing geometry of 15 different worm gear toothings. The results of this step confirm the modeled results.

The lead on the right and left tooth surfaces of worms is the same. However, the lead can be varied along the worm shaft. This is called dual lead worm gear, and is used to eliminate play in the main worm gear of hobbing machines. The pitch diameters of worm modules are equal. The same principle applies to their pitch diameters. Generally, the lead angle increases as the number of threads decreases. Hence, the larger the lead angle, the less self-locking it becomes.

worm gears in fishing reels

Fishing reels usually include worm shafts as a part of the construction. Worm shafts in fishing reels allow for uniform worm winding. The worm shaft is attached to a bearing on the rear wall of the reel unit through a hole. The worm shaft’s front end is supported by a concave hole in the front of the reel unit. A conventional fishing reel may also have a worm shaft attached to the sidewall.

The gear support portion 29 supports the rear end of the pinion gear 12. It is a thick rib that protrudes from the lid portion 2 b. It is mounted on a bushing 14 b, which has a through hole through which the worm shaft 20 passes. This worm gear supports the worm. There are two types of worm gears available for fishing reels. The two types of worm gears may have different number of teeth or they may be the same.

Typical worm shafts are made of stainless steel. Stainless steel worm shafts are especially corrosion-resistant and durable. Worm shafts are used on spinning reels, spin-casting reels, and in many electrical tools. A worm shaft can be reversible, but it is not entirely reliable. There are numerous benefits of worm shafts in fishing reels. These fishing reels also feature a line winder or level winder.

worm gears in electrical tools

Worms have different tooth shapes that can help increase the load carrying capacity of a worm gear. Different tooth shapes can be used with circular or secondary curve cross sections. The pitch point of the cross section is the boundary for this type of mesh. The mesh can be either positive or negative depending on the desired torque. Worm teeth can also be inspected by measuring them over pins. In many cases, the lead thickness of a worm can be adjusted using a gear tooth caliper.

The worm shaft is fixed to the lower case section 8 via a rubber bush 13. The worm wheel 3 is attached to the joint shaft 12. The worm 2 is coaxially attached to the shaft end section 12a. This joint shaft connects to a swing arm and rotates the worm wheel 3.

The backlash of a worm gear may be increased if the worm is not mounted properly. To fix the problem, manufacturers have developed duplex worm gears, which are suitable for small backlash applications. Duplex worm gears utilize different leads on each tooth face for continuous change in tooth thickness. In this way, the center distance of the worm gear can be adjusted without changing the worm’s design.

worm gears in engines

Using worm shafts in engines has a few benefits. First of all, worm gears are quiet. The gear and worm face move in opposite directions so the energy transferred is linear. Worm gears are popular in applications where torque is important, such as elevators and lifts. Worm gears also have the advantage of being made from soft materials, making them easy to lubricate and to use in applications where noise is a concern.

Lubricants are necessary for worm gears. The viscosity of lubricants determines whether the worm is able to touch the gear or wheel. Common lubricants are ISO 680 and 460, but higher viscosity oil is not uncommon. It is essential to use the right lubricants for worm gears, since they cannot be lubricated indefinitely.

Worm gears are not recommended for engines due to their limited performance. The worm gear’s spiral motion causes a significant reduction in space, but this requires a high amount of lubrication. Worm gears are susceptible to breaking down because of the stress placed on them. Moreover, their limited speed can cause significant damage to the gearbox, so careful maintenance is essential. To make sure worm gears remain in top condition, you should inspect and clean them regularly.

Methods for manufacturing worm shafts

A novel approach to manufacturing worm shafts and gearboxes is provided by the methods of the present invention. Aspects of the technique involve manufacturing the worm shaft from a common worm shaft blank having a defined outer diameter and axial pitch. The worm shaft blank is then adapted to the desired gear ratio, resulting in a gearbox family with multiple gear ratios. The preferred method for manufacturing worm shafts and gearboxes is outlined below.

A worm shaft assembly process may involve establishing an axial pitch for a given frame size and reduction ratio. A single worm shaft blank typically has an outer diameter of 100 millimeters, which is the measurement of the worm gear set’s center distance. Upon completion of the assembly process, the worm shaft has the desired axial pitch. Methods for manufacturing worm shafts include the following:

For the design of the worm gear, a high degree of conformity is required. Worm gears are classified as a screw pair in the lower pairs. Worm gears have high relative sliding, which is advantageous when comparing them to other types of gears. Worm gears require good surface finish and rigid positioning. Worm gear lubrication usually comprises surface active additives such as silica or phosphor-bronze. Worm gear lubricants are often mixed. The lubricant film that forms on the gear teeth has little impact on wear and is generally a good lubricant.

in Diwaniyah Iraq sales price shop near me near me shop factory supplier Nmrv 063 Gear Motor Actuator Reducer Chain Drive Gear Box 1 1 Ratio 90 Degree Gear Box Hitachi Excavator Slewing Gearbox manufacturer best Cost Custom Cheap wholesaler

“We are constantly serving our customers with our ideal merchandise.” EPG has established up a total set of high quality administration technique which is supplied with superior inspection and examination gear. we have received the have confidence in of consumers throughout the world.

Minimal EPT NMRV collection worm EPT used maritime EPT for sale,low cost worm EPT box rates for textile EPTs

Product Description

NMRV Utilized Maritime EPT

1. Mad of high-high quality EPT alloy,ligEPT weigEPT and non-rusting

2. Massive output torque

3. Easy in working and low in sounds,can function EPT time in dreadful situations.

four. Substantial in radiating performance.

five. Great-looking in appearance,sturdy in support existence and small in quantity.

six. Ideal for omnibearing installation.

| Design No.: | NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

| Ratio: | five,seven.5,10,15,twenty,twenty five,thirty,forty,fifty,sixty,80,one hundred |

| Coloration: | Blue(Ral5571)/Silver Gray (RAL9006) Or On Consumer Request |

| EPT: | EPT: Measurement twenty five-one hundred ten Is EPT Alloy, Measurement 110-150 Is Cast-Iron |

| Worm Wheel: ZCuSn10Pb1 | |

| Worm:20Cr | |

| Pinion:Tin Bronze | |

| Output Shaft: Steel-forty five# | |

| Usages: | EPT EPT: Food Stuff, Ceramics, Chemical, EPT, Dyeing,EPT working, Glass. |

| IEC Flange: | IEC StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Flange Or On Consumer Request |

Business Info

EPT management

EPT

EPT Specifics: StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd carton/Pallet/StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd wooden scenario

Delivery Details : 15-thirty working daEPTupon payment

Our Certifications

Connected Product

EPT Planetary EPT

| EPT Planetary EPT | Robot RV EPT pace EPT |

| Personalized produced Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted EPT | 8000 Series Cycloidal EPT |

| SLT Series Spiral EPTl EPT | SLSWL Sequence Worm Screw Jack |

| SLP Sequence Planetary EPT | SLH/SLB Series Substantial EPT EPT |

| NMRV Collection Worm EPT | BKM Series Helical-hypoid EPT |

| SLRC Sequence Helical EPT | SLSMR Series Shaft Mounted EPT |

| SLXG Series Shaft Mounted EPT | X/B Collection Cycloidal EPT |

| SLR/SEPT/SLK/SLS Sequence Helical EPT | AC/DC EPT |

FAQ

one.Payment Time period: TT, L/C

two.Shipping and delivery time: about thirty daEPTfrom EPT payment.

3.We accept tailored goods as for each your EPT requirement.

4.XiHu (West Lake) Dis.hu (West Lake) Dis.strains for the Selection:Usually we can select a single EPT which is appropriate for you with some informations from you,this sort of as ratio/motor speed/mounting dimension/ out torque etc.

five.If the least orEPTamount is in extra of $10000, there are preferential.

Q1: What info ought to I tell you to confirm the item?

A:Product/Dimensions, EPT Ratio, Shaft directions amp OrEPTquantity.

Q2: What can i do if I do not know which one particular EPT?

A:Dont worry, Ship as a lot information as you can, our team will assist you uncover the rigEPT one you are hunting for.

Q3: What is your product guarantee time period?

A:We supply one yr guarantee since the vessel departure date remaining EPT.

This autumn: Are you trading company or maker ?

A: We are manufacturing facility.

Q5: How EPT is your delivery time?

A: EPTly it is 5-10 daEPTif the goods are in stock. or it is fifteen-twenty daEPTif the merchandise are not in stock, it is according to amount.

Q6: Do you offer samples ? is it totally free or extra ?

A: Sure, we could supply the sample for free demand but do not pay out the EPT of freight.

Q7: What is your terms of payment ?

A: Payment lt=1000USD, one hundred% EPT. Payment gt=1000USD, thirty% T/T EPT ,equilibrium ahead of shippment.

If you have an additional concern, pls feel cost-free to contact us as beneath:

Contact Us

in Tlaxcala Mexico sales price shop near me near me shop factory supplier 12mm 3 Volt DC Spur Gear Motor with Micro Gearbox manufacturer best Cost Custom Cheap wholesaler

Our solution range also covers locking assemblies (clamping elements/locking gadget), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes. EPG is a expert manufacturer and exporter that is worried with the layout, advancement and manufacturing. We provide OEM support.

12mm three Volt DC Spur Gear EPT With Micro EPT

Solution Description

- Technical specs:

-

- Rated voltage: 3. V DC

- Rotation course: CW/CCW

- Reduction ratio: one hundred forty four/one

- Running temperature assortment: -10-50 ordmC

- Storage temperature assortment: -20-sixty ordmC

- General duration: 32.1mm

- EPT size: 17.1mm

- Rated torque of EPT: 600gf.cm

- Instant torque of EPT: 1,200gf.cm

- Output EPT: .01-.6W

- Output Shaft: EPT

- No load:

- Speed: seventy seven rpm

- Recent: 90mA

- On Load:

- Rated speed: 69rpm

- Rated current: 135mA

- Rated torque: 122gf.cm

| Product | Application Parameters | Rated Torque of Equipment Box | Quick Torque of Gear Box | Gear Ratio | Gear Box Length L1 |

|||||||

| Rated | At No Load | At Rated Load | Overall Duration L |

|||||||||

| Voltage | Speed | Present | Velocity | Recent | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWPD012012-sixteen | 3. | 717 | 90 | 625 | 130 | eighteen | one.8 | 28.three | 400 | 800 | 16 | 13.three |

| ZWPD012012-24 | three. | 478 | 90 | 417 | one hundred thirty | 27 | 2.six | 400 | 800 | 24 | ||

| ZWPD012012-36 | three. | 319 | 90 | 278 | a hundred thirty | 41 | 4. | 400 | 800 | 36 | ||

| ZWPD012012-64 | 3. | 174 | 90 | 156 | a hundred thirty five | 54 | 5.three | 32.one | 600 | 1200 | sixty four | 17.one |

| ZWPD012012-ninety six | three. | 116 | 90 | 104 | a hundred thirty five | eighty one | 7.nine | 600 | 1200 | ninety six | ||

| ZWPD012012-a hundred and forty four | three. | seventy seven | 90 | sixty nine | one hundred thirty five | 122 | eleven.9 | 600 | 1200 | one hundred forty four | ||

| ZWPD012012-216 | three. | 52 | ninety | forty six | one hundred thirty five | 182 | seventeen.9 | 600 | 1200 | 216 | ||

| ZWPD012012-256 | 3. | forty four | ninety five | 39 | one hundred thirty five | 162 | 15.9 | 35.9 | 850 | 1700 | 256 | 20.9 |

| ZWPD012012-384 | 3. | 29 | ninety five | 26 | a hundred thirty five | 243 | 23.eight | 850 | 1700 | 384 | ||

| ZWPD012012-576 | three. | 19 | 95 | 17 | 135 | 365 | 35.seven | 850 | 1700 | 576 | ||

| ZWPD012012-864 | 3. | thirteen | ninety five | twelve | a hundred thirty five | 547 | fifty three.six | 850 | 1700 | 864 | ||

| ZWPD012012-1296 | 3. | nine | ninety five | eight | one hundred thirty five | 820 | eighty.4 | 850 | 1700 | 1296 | ||

over requirements just for reference and customizable in accordance to requirements.

2d Drawing:

Merchandise details show

Software

|

Audio and visual equipments |

notebook Laptop, camcorder, auto DVD, kinescope DVD, automobile CD player, digital camera, EPT digicam, headphone stereo, cassette EPT recorder and etc. |

|

EPT application |

electric shaver, tooth brush, kitchen EPTs, hair clipper, sewing EPTs, massager, vibrator, hair dryer, rubdown EPT, corn popper, scissor hair EPT, EPT cleaner, XiHu (West Lake) Dis.Hu (West Lake) Dis.den resource, sanitary ware, window curtain, espresso EPT, whisk and etc. |

|

Place of work EPT equipments |

CD-ROM, OA equipments, scanners, printers, multifunction EPTs duplicate EPTs, fax, FAX paper cutter, laptop peripheral, financial institution EPT and and many others. |

|

EPTmotive products |

conditioning damper actuator, doorway lock actuator, retractable rearview mirror, meters, optic aXiHu (West Lake) Dis.s management device, head ligEPT beam degree adjuster, vehicle water pump, automobile antenna, lumbar assistance, computerized vending EPT and and so on. |

|

ToEPTand designs |

radio management design, automatic cruise control, ride-on toy and etc. |

|

Healthcare application |

blood pressure meter, breath EPT and etc. |

|

EPTs |

air freshener, show, flow manage valves and and so on. |

|

Electric EPT instruments |

electric drill, screwEPTr and etc. |

|

EPT devices |

keep track of, optics instruments and etc. |

Our Companies:

- ODM amp OEM

- EPT design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment

- Relevant EPT support

EPT amp EPT

1) EPT Specifics

packed in EPT firstly, then carton, and then strengthened with wooden circumstance for outer EPT.

Or according to client’s requirement.

2) EPT Specifics

samples will be transported in 10 days

batch orEPTleading time in accordance to the genuine situation.

Organization Info:

HangEPT EPT EPTry amp Electronics Co., Ltd was estabEPTd in 2001,We offer the overall EPT resolution for clients from layout, tooling fabrication, factors producing and assembly.

one) Competitive Benefits

- one) Aggressive Benefits

19 yr experience in production motor EPT

We provide technical support from r ampd, prototype, testing, assembly and serial generation , ODM ampOEM

Aggressive Value

Merchandise Efficiency: Reduced sounds, Large efficiency, EPT lifespan

Prompt Shipping and delivery: fifteen operating daEPTafter payment

Tiny Orders Accepted

two) Major EPT

-

EPT reduction EPT and its diameter:three.4mm-38mm,voltage:1.five-24V,EPT: .01-40W,output pace:five-2000rpm and output torque:one. gf.cm -50kgf.cm,

- Custom-made worm and EPT EPT EPTry

- Exact EPT motion module

- Precise part and assembly of plastic and steel powEPTEPT.

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and more…

FAQ

one. Can you make the EPT with custom specifications?

Sure. We have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment group, also a great phrase of engineers, each and every of them have

many work years expertise.

two.Do you offer the samples?

Sure. Our organization can provide the samples to you, and the shipping time is about five-15daEPTaccording to the specification of EPT you want.

three.What is your MOQ?

Our MOQ is 2000pcs. But at the commencing of our enterprise, we accept modest purchase.

four. Do you have the product in inventory?

I am sorry we donot have the product in stock, All items are manufactured with orders.

five. Do you give EPT assist?

Of course. Our business have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment crew, we can supply EPT assist if you

need.

6.How to ship to us?

We will ship the goods to you in accordance to the DHL or UPS or FEDEX and so forth account you provide.

seven.How to pay out the money?

We accept T/T EPT. Also we have various bank account for acquiring funds, like US dollors or RMB and so forth.

8. How can I know the merchandise is suitable for me?

Frist, you need to give us the much more details info about the item. We will advocate the item to you according to your necessity of specification. Right after you validate, we will get ready the samples to you. also we will offer you some excellent EPTs according to your item use.

nine. Can I come to your business to pay a visit to?

Indeed, you can occur to our business to pay a visit to at at any time, and welcome to pay a visit to our company.

ten. How do make contact with us ?

Remember to send out an inquiry

China manufacturer & factory supplier for BKM in Tirupati India Helical Hypoid Gear reducer price mini bevel gearbox worm drive shaft gear box zero backlash worm reducer zero backlash worm With high quality best price & service

Maker of roller push chains for electricity transmission applications from standard industrial to operations in specialized areas such as meals processing, hefty construction gear, and oil area companies. Available in double pitch generate and regular roller chains with solitary and a number of strand configuratMost generally, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be run right by the engine.ions. Technical specs contain .25 to 3 in. chain pitch, .13 to 1.88 in. distance amongst sidebars, and .09 to .ninety four in. pin diameter. Available with attributes such as circumstance-hardened and armor-cased pins, pre-pressured method, corrosion and shock resistance, and stainless metal components. Gives put up-sale assist companies.PersonnelOur sales people are well skilled to accommodate your requests and talk English for your usefulness.

Overview

Swift Details

- Relevant Industries:

-

Developing Material Retailers

- Gearing Arrangement:

-

Hypoid

- Output Torque:

-

a hundred~750N.m

- Input Velocity:

-

1400rpm

- Output Velocity:

-

4~187RPM

- Spot of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

Our merchandise is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The us, Thailand, Pakistan, Indonesia, a lot more than sixty international locations and locations.

- Color:

-

Blue / Grey / Client need

Provide Capacity

- Offer Capability:

- 5000 Set/Sets per Thirty day period

Packaging & Delivery

- Packaging Specifics

- A single set in one Carton,then set in massive wood.

- Port

- Chinese Port

On the web Customization

EPG is a chief firm in services and trading efficiency, in the area of Gears.

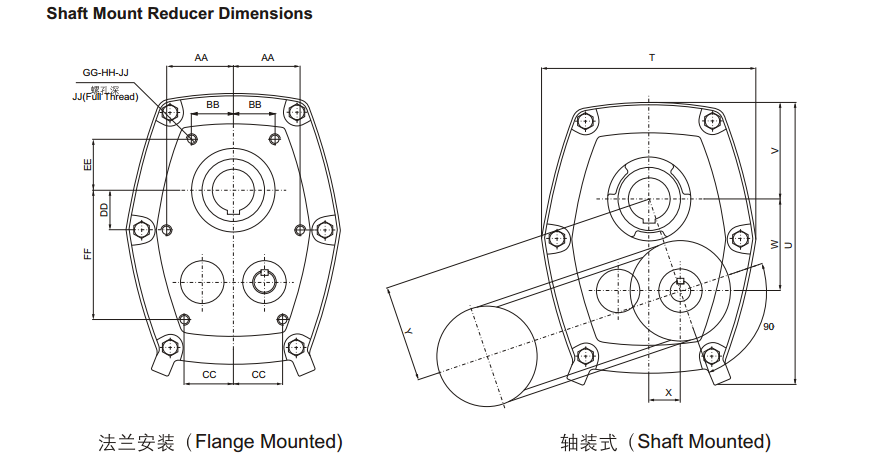

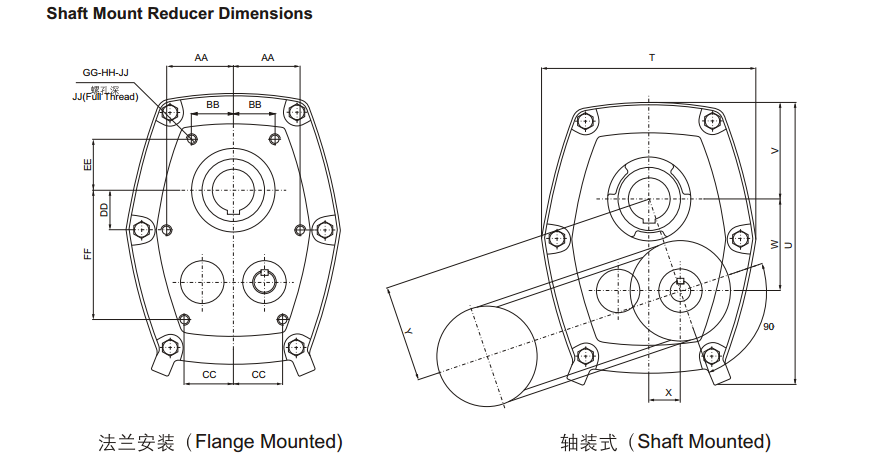

Product Description

one. Generate by hypoid gear, has large ratios.

two. Large in output torque, high performance, vitality conserving and environmental safety.

3. Made of higher high quality aluminum alloy, gentle in excess weight and non-rusting

4. Easy in working and minimal in sound, can perform extended in dreadful situations.

5. Good-searching in appearance, sturdy in provider existence and modest in volume.

6. Suitable for all round set up, vast application and straightforward of use.

seven. The Mounting Dimension of BKM collection are compatible with NMRV series worm gear device (A element of NMRV050 dimensions are different from BKM050)

eight. Modular and multi-structure can fulfill the calls for of different circumstances.

|

Sort |

BKM50,BKM63,BKM75,BKM90,BKM110 |

|

Transmission Phase |

B: 2 stages |

|

C: 3 levels |

|

|

Ratio |

B: 7.5,10,twelve.5,fifteen,twenty,twenty five,30,forty,50,sixty |

|

C: 50,60,75,a hundred,125,one hundred fifty,200,250,300 |

|

|

Output torque |

Up to 500N.m |

|

Motor electricity |

.twelve~5.5KW,with flange:B5 or B14 |

|

Housing content |

Aluminum alloy |

|

Output shaft |

substance: 40Cr |

|

Hardness amount: 242-286HB |

|

|

Helical equipment |

Material:20CrMnTi |

|

Hardness level: fifty eight-62HRC |

|

|

Precision degree:6 quality |

|

|

Transmission efficiency |

B:92%-94% |

|

C:90%-ninety two% |

|

|

Oil seal brand name |

SKF |

|

Bearing |

C&U |

|

Lubricant |

Mineral oil or artificial oil |

Certifications

Trade Exhibits

Packaging & Delivery

Packing Specifics : Standard carton/Pallet/Normal wooden case

Supply Details : 15-thirty operating days upon payment

Company Details

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Personalized created Non-standard Gearbox | UDL Sequence Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series Higher Energy Reducer |

| NMRV Collection Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Relevant Merchandise

Speak to

Best China manufacturer & factory TXT in Verona Italy Type Gearbox Conveyor Gear box manufacturer With high quality best price

Our products are manufactured by modern computerized machinery and equipment.a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

2.68-134.2N.m

How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.

- Input Speed:

-

1440rpm

- Output Speed:

-

10-407rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

We warmly welcome the friends from all the world!

OEM

- Model Number:

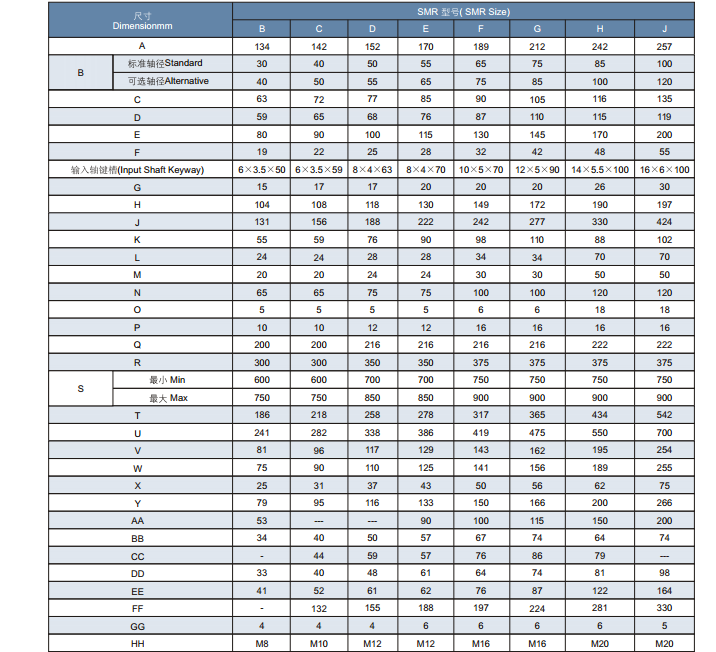

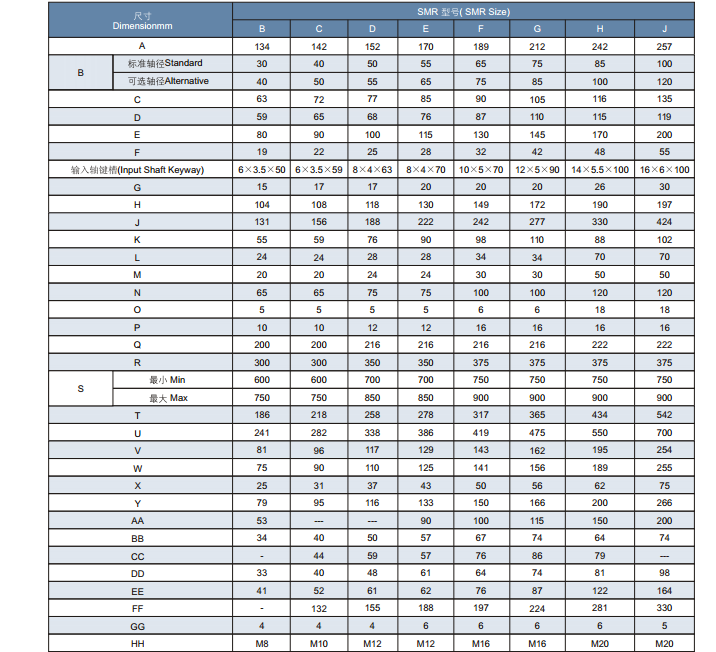

-

SMR

- Rated Power:

-

2-130KW

- Product Name:

-

TXT Type Gearbox Conveyor Gear box manufacturer

- Solution:

-

Mining, Belt Drive, Conveyor

- Size:

-

B-J

- Lubrication:

-

Synthetic Oil, Mineral Oil

- Warranty:

-

12 Months

- Certificate:

-

CE; ISO9001

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Standard export packing and wood pallet packing

- Port

- Shanghai or Ningbo Port

Online Customization

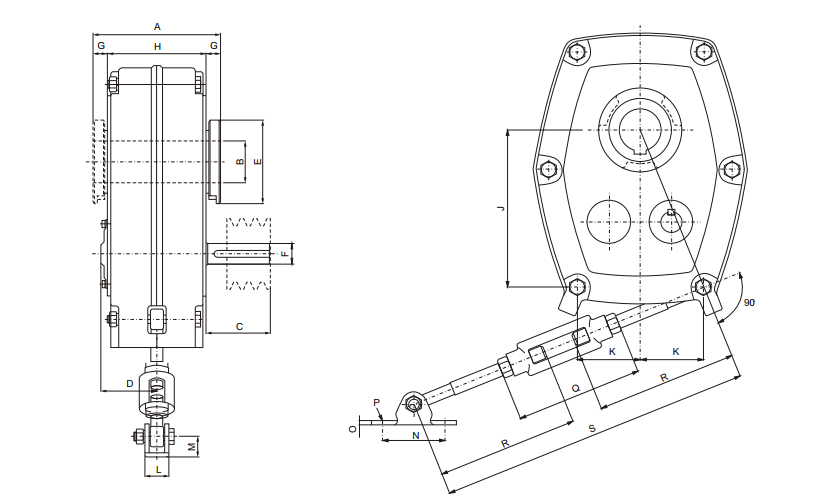

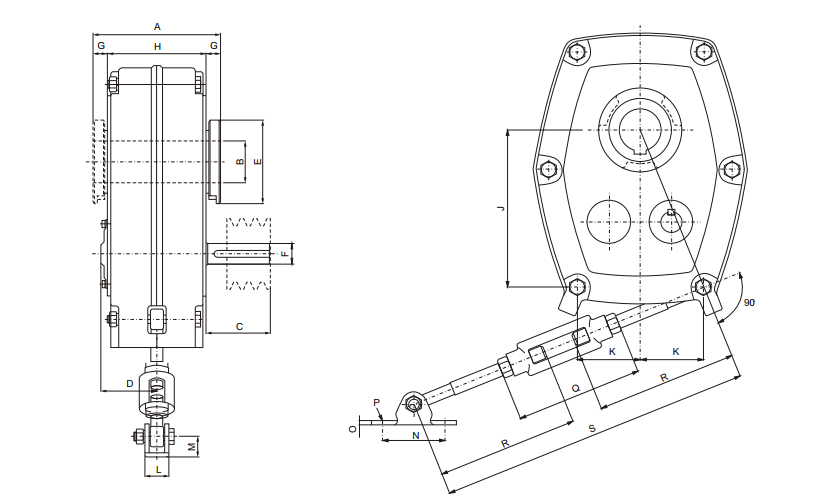

Detailed Images

Images of TXT Type Gearbox Conveyor Gear box manufacturer

Packing & Delivery

Packing Images of TXT Type Gearbox Conveyor Gear box manufacturer

Inner Packing: PP bag with carton;

Outer Packing: Wooden case;

Shipment: 14-20 days upon receiving the deposit.

Related Products

SEW Type Gearbox with Motor

FR Helical Gearbox with Motor

Cast Iron Worm Gearbox

NMRV Worm Gearbox

SMR Shaft MouThis novel breather plug features a spring that prevents oil bubbles from forming and percolating to the outside.nted Gearbox

Dodge TXT Type Shaft Mounted Gearbox

About Us

Ever_power GROUP is the first and largest worm gearbox manufacturer in China, established in 1976, specialising in the production of a wide variety of transmission machinery. With more than 40 years experience in the industry, our assets now total 117.2 million dollars, and we have 2 subsidiary companies, 8 holding companies, and 12 joint-stock companies.

We can produce 400,000 units of worm gearboxes, 100,000 units of gear reducers, 50,000 units of other speed reducers, 150,000 units of flexible couplings, and 100,000 units of speed-reducer accessories every year.

70% of our products have been exported to 40 more countries, and our customers come from Italy, Germany, USA, Canada, Spain, UK, India, Mexico, Brazil, Argentina, Turkey, Singapore and other main industrial countries. 30% of them are OEM made for direct manufacturers of other products.

FAQ

Q1. Is your quality good?

A1: Quality never tell lies, we’re the largest manufacturer and exporter of worm gear reducer in Asia, the first reducers and gearboxes manufacturer in China, who has been given license since 1993. Also, we had achieved ISO9001 and CE Certificate among all manufacturers.

Q2. How is your price? Can you offer any discount?

A2: We will give the best price we can base on your needs and the quantities.

Q3. Do you offer any visiting?

A3: Yes! We sincerely invite you to visit us! We can pick you from airport, railway station and so on. Also, we can arrange housing for you. Please let us know in advanced.

Q4. When is the best time to contact you?

A4: You can contact us by email any time, we will reply you ASAP. If you want contact by phone, our working hour is Mon-Sat 9am-17:30pm.

Contact

Ever_power GROUP

Address: No.789-B8Shenhua Road, XiHu Dsitriction Enco&Tech Development Zone HangZhou City, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Website: www.hzpt.com

Best China manufacturer & factory Belt Conveyor Gear Box planetary gear motoreductor speed increaser gearbox reverse gearbox small differential gear box With high quality best price

Our product range also covers locking assemblies (clamping elements/locking device), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

137~9800 N.m

- Within our field of work is adapting our reducers from the catalogue to our costumer´s necessity by means of flanges, shafts, extensions, supports, etc. according to the necessities of their machines. Input Speed:

-

1400rpm

- Output Speed:

-

46~280RPM

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue / Grey / Customer requirement

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- wooden Case per pc + many pcs in wooden case or as requested

- Port

- Chinese Port

-

Lead Time

: -

Quantity(Boxes) 1 – 5 >5 Est. Time(days) 35 To be negotiated

Online Customization

Product Description

Product Application

Conveyor & Material Handling

Mining & Quarry

|

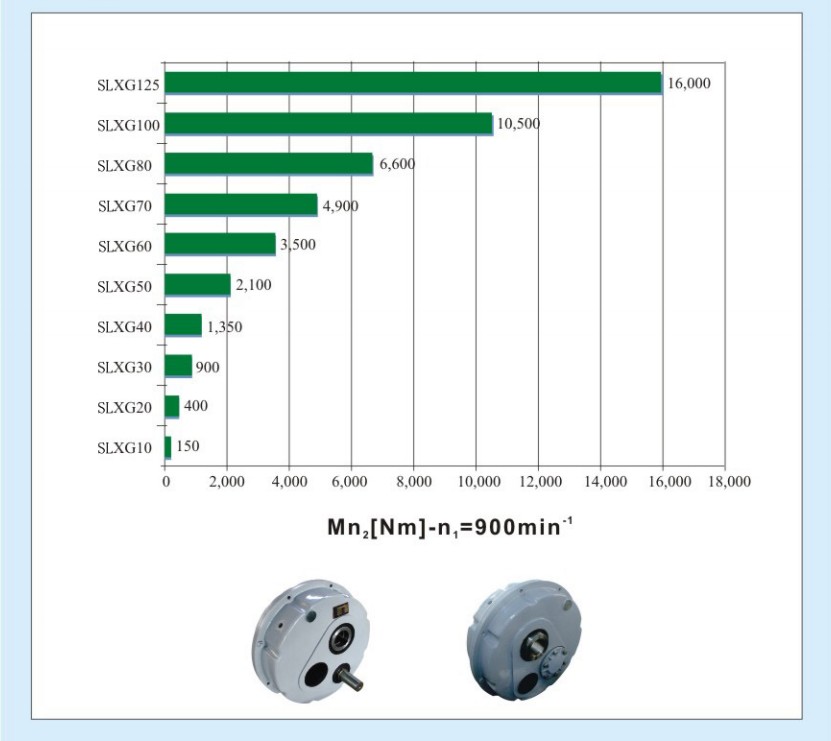

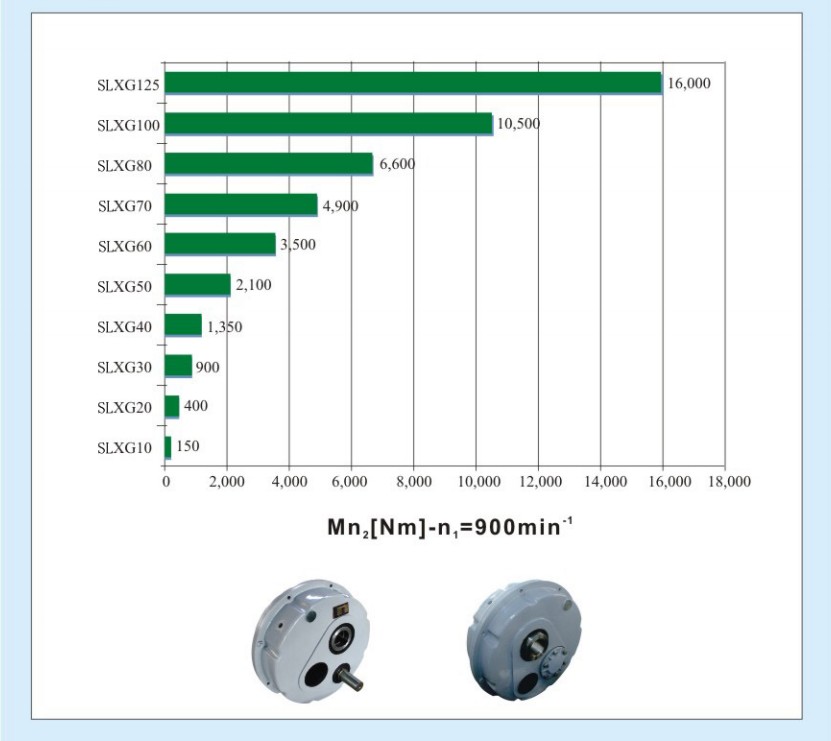

SLXG Shaft Mounted Reducer |

Output Shaft Bore [mm] |

Ratio(i) |

Rated torque |

|

SLXG30 |

Φ30 |

7, 10, 12.5 |

180N.m |

|

SLXG35 |

Φ35 |

5,10,15,20,25 |

420N.m |

|

SLXG40 |

Φ40 |

5,10,12.5,15,20,25 |

900N.m |

|

Φ45 |

|||

|

SLXG45 |

Φ45 |

5,10,12.5,15,20,25 |

1400N.m |

|

Φ50 |

|||

|

Φ55 |

|||

|

SLXG50 |

Φ50 |

5,10,12.5,15,20,25 |

2300N.m |

|

Φ55 |

|||

|

Φ60 |

|||

|

SLXG60 |

Φ60 |

5,10,12.5,15,20,25 |

3600N.m |

|

Φ70 |

|||

|

SLXG70 |

Φ70 |

5,10,12.5,15,20,25,31 |

5100N.m |

|

Φ85 |

|||

|

SLXG80 |

Φ80 |

5,10,12.5,15,20,25,31 |

7000N.m |

|

Φ100 |

|||

|

SLXG100 |

Φ100 |

5,10,12.5,15,20,25,31 |

11000 |

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series HelicaThe company was certified by ISO9001:2008 Quality Management System.l-hyThe EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design.poid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

Best China manufacturer & factory Good quality RC series helical gear box gearbox speed reducer high speed forward reverse gearbox With high quality best price

The new products include a series of high-tech and high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-speed tooth chains, timing chains, self-lubricatOur products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.ion chains, among which have type high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Details

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction The star tube is suitable for applications with high torque peaks that could be harmful to the other tube shapes. The star tube with 6 contact points is also the preferred choice when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG series with splined tube The splined tube is suggested for very short PTO shafts. The splined telescopic shaft allows bushing and splined couplings of only 100-120mm. The dimensions of the cross joints vary from 22mm diameter up to 48mm diameter and allow power transmission of up to 250HP.works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

3.5~500N.m

- Input Speed:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

3.77~50.4

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C&U,LYC, HRB,ZWZ,NSK

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

A worm gearbox consists of a cylinder with a spiral groove mounted on a shaft. A gear meshes with the spiral groove on the cylinder, and when the cylinder rotates, it causes the gear to rotate also.

Online Customization

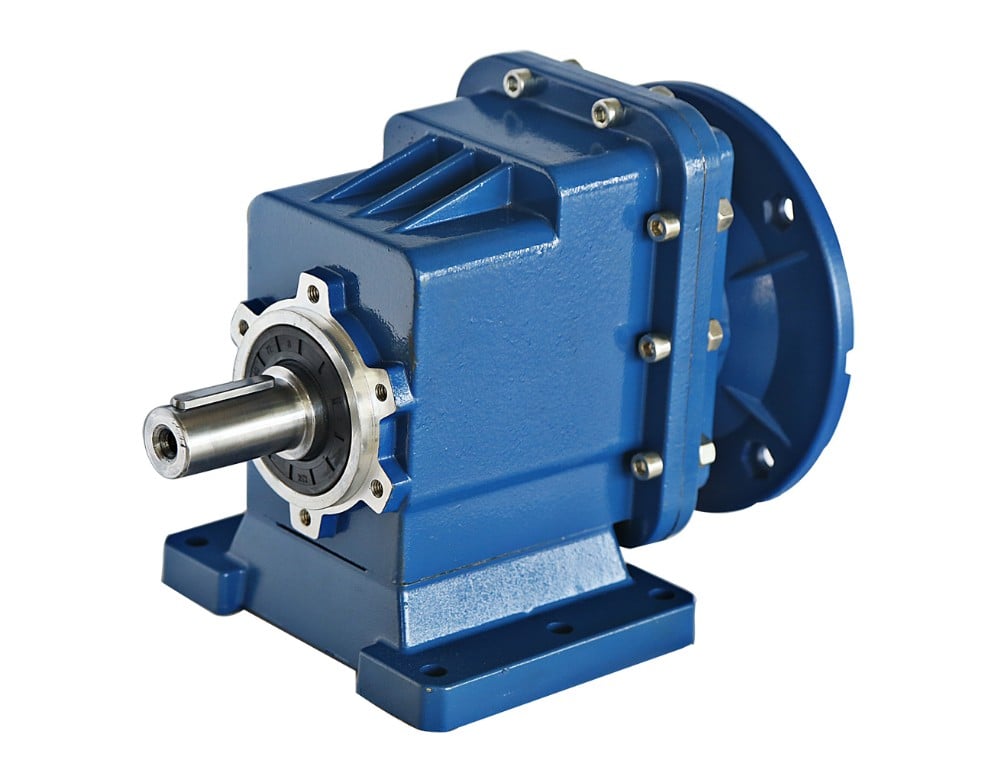

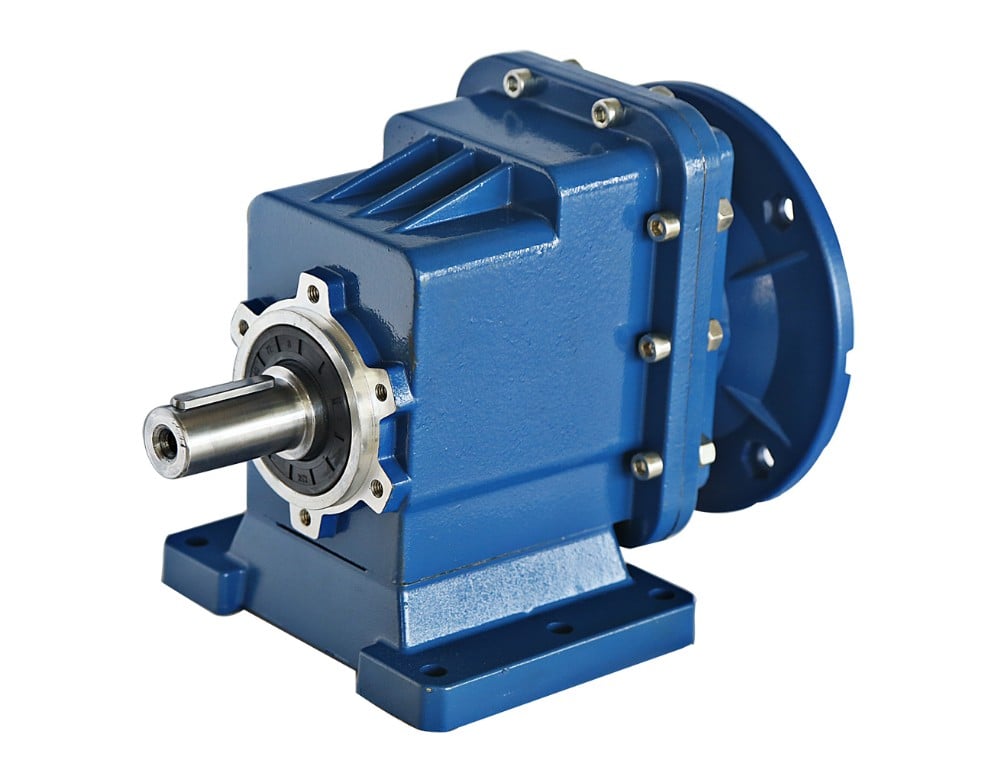

Products Description

Die-cast aluminum cabinet, light weight and good strength. The surface is specially treated, the appearance is not easy to scratch

Exquisite design, compact structure, low noise

Helical gear design, tooth meshing rate is generally more than twice that of spur gears, with the characteristics of stable operation, high output torque and low backlash

Related product

Company Profile

Packing & Delivery

Helical-worm China Motor Reducer S47 SF47 SA47 SAF47 SAT47 SAZ47 Helical Worm Gear Speed Reducer gearbox motor electric – Supplier Manufacturer wholesaler Factory

For a lot more information.: Cellular/Whatpp: +8613083988828

Our patented coupling mechanism C Line is the outcome of our information and growth. It permits effortless coupling and uncoupling of the PTO generate shaft. The include delivers the person more comfort because of its ergonomically and compact kind. The users’ safety is confident, simply because he can’t get entangled in protruding elements of the yoke. There is also less dust present at managing and there are fewer problems connected with it.The custom-made gearboxes developed by EPG are meant for use on a wide assortment of agricultural machinery. They have been engineered for use on products such as mowers, grain conveyors, rice harvesters, excavators, and so on.Trying to keep in head that good services is the important to cooperating with clientele, we try to satisfy higher high quality specifications, offer you competitive prices and guarantee prompt delivery. EPG main production is of farming fifteen-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Overview

Swift Particulars

- Relevant Industries:

-

Constructing Materials Stores

- Gearing Arrangement:

-

Worm

- Output Torque:

-

one hundred~62800N.m

- Enter Velocity:

-

1450 / 960rpm

- Output Velocity:

-

fourteen-280rpm

- Spot of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Usage:

-

Industrial Equipment

- Type:

-

Servo Motor

- Safeguard Function:

-

Waterproof

- Coloration:

-

silver or blue

- Mount Placement:

-

Foot Mounted

- Certification:

-

ISO9001-2008

Packaging & Shipping

-

Direct Time

: -

Quantity(Boxes) one – 1 >1 Est. Time(times) 15 To be negotiated

On the internet Customization

Product Description

Helical-worm Motor Reducer S47 SF47 SA47 SAF47 SAT47 SAZ47 Helical Worm Equipment Pace Reducer gearbox motor electric

Merchandise Software

S collection sound shaft helical worm 220v ac equipment motor gearbox is 1 type of Helical worm gearbox ,created as Modularization and higher-stainless cast iron situation . It is mix of helical gear and worm equipment ,which with larger efficiency and energy than basic aluminum worm gearbox . Due to their outstanding efficiency, these drives can be used in each industrial sector and personalized to individual torque and speed demands. The equipment ratios afforded by the helical-worm equipment phase and the reduced sounds ranges for the duration of procedure make these gearmotors perfect reduced-cost solutions for basic apps

1) Output pace: .6~one,028r/min

2) Output torque: up to 4530N.m

three) Motor electrical power: .twelve~22kW

four) Mounted sort: foot-mounted and flange-mounted mounting

| Equipment Material | 20CrMnTi |

| Circumstance Materia | HT250 |

| Shaft Substance | 20crmn |

| Gear Processing | Grinding complete by HOFLER Grinding Equipment |

| Color | Custom-made |

| Sounds Check | Bellow 65dB |

| Machining precision of gears | exact grinding, six Grade |

| Warmth treatment | tempering, Cementating, quenching, and so on |

| Brand of bearings | C&U HRB. LYCZWZ SKFNSK |

| Model of oil seal | NAK or other model |

| Sounds(MAX) | sixty five-70dB |

| Temp rise (MAX) | 40C |

| Temp increase(Oil)(MAX) | 50C |

Major Features

1) Basic construction in linear type ,effortless in set up and maintation.

two) Adopting innovative world renowned brand elements in pneumatic areas ,electric areas and procedure parts.

3) Substantial pressure double crank to handle the die opening and closing.

4) Operating in a substantial automatization and intellectualization,no pollution

5) Apply a linker to join with the air conveyor ,which can right inline with filling equipment .

Organization Information

Good quality management

Packing&Shipping and delivery

Packing Details: Common carton/Pallet/Normal wood case

Delivery Specifics : fifteen-thirty working times on payment

Our Certifications

Relevant Product

FAQ

1.Payment Phrase: TT, L/C

two.Shipping and delivery time: about 30 times from acquire payment.

3.We acknowledge custom-made merchandise as for each your particular need.

4.Guidelines for the Variety:Normally we can choose 1 equipment which is suitable for you with some informations from you,this sort of as ratio/motor speed/mounting dimension/ out torque etc.

five.If the minimum purchase quantity is in excess of $ten thousand, there are preferential.

Q1: What information should I tell you to confirm the product?

A:Model/Dimensions, Transmission Ratio, Shaft directions & Order quantity.

Q2: What can i do if I will not know which 1 I need?

A:Dont worry, Send out as considerably data as you can, our crew will assist you find the right 1 you are seeking for.

Q3: What is your solution warranty time period?

A:We offer a single year guarantee because the vessel departure day left China.

If you have one more query, pls come to feel free to speak to us.

Speak to Us

EPG – one of the largest transmission manufacturing facility in China, principal merchandise: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare areas and agricultural elements manunfacuter in China /For more info.: Mobile/Whatpp: +8613083988828