Issue: New

Guarantee: 6 Months

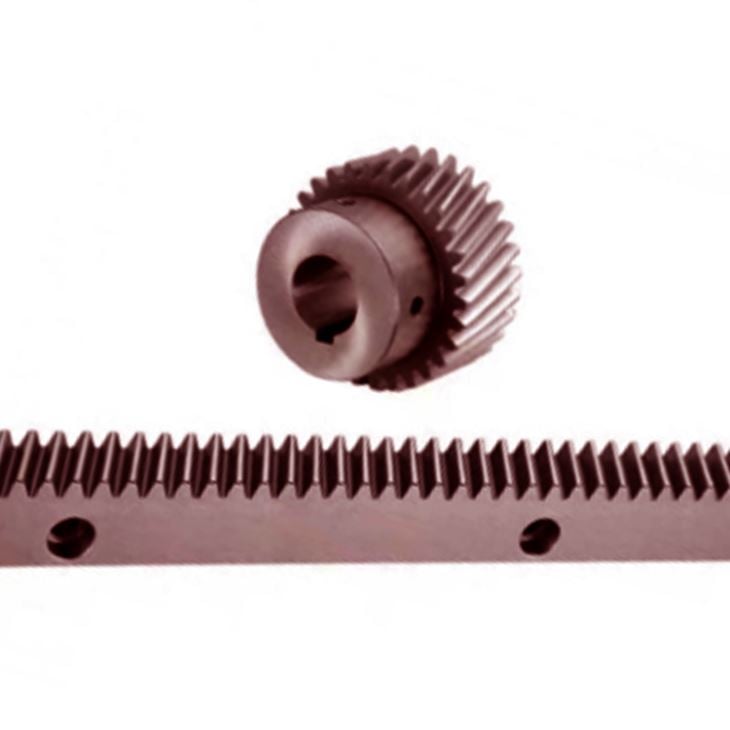

Form: Spur

Relevant Industries: Producing Plant, Equipment Mend Stores, Residence Use, Construction works , Other, Transmission Drive, Transmission Gearbox, Generate

Fat (KG): 1

Showroom Spot: None

Online video outgoing-inspection: Provided

Equipment Check Report: Presented

Marketing and advertising Kind: New Product 2571

Guarantee of main factors: 6 Months

Main Factors: PLC, Motor, Bearing, Gearbox, Motor, Strain vessel, Equipment, Industrial Heavy Duty Immediate 10HP 15HP 20HP hp 30HP 22KW 18.5KW 15KW 11KW 7.5KW Integrated Rotary Screw Air Compressor Pump, Equipment

Material: personalized

Tooth Profile: Straight Bevel, Straight Bevel

Quality: 5-ten

Machining Precision: .01mm

Processing: Hobbing

Warmth remedy: Tempering

Dimension: Tailored Size

Right after Warranty Service: Video clip Online Support

Port: HangZhou/ZheJiang

Packaging Particulars: box per Customized Cnc Machining Stainless Steel Pinion Gear Shaft Steel Spur Gear Brass Small Spiral Angular Straight Bevel Gears

Port: HangZhou

Customized Cnc Machining Stainless Metal Pinion Gear Shaft Metallic Spur Gear Brass Small Spiral Angular Straight Bevel Gears

Spur Gear

| Merchandise | Equipment |

| Module | M0.3-M10 |

| Precision quality | DIN6, DIN7, DIN8, DIN10 |

| Strain angle | fourteen.5 degree, 15 degree, 20 degree |

| Material | C45 steel,20CrMo,40Cr, brass, nylon, POM, 20CrMnTi, NMRV030 velocity reducer, handbook worm gearbox screw jack and so on |

| Warmth treatment method | Hardening and Tempering Substantial Frequency Quenching Carburization and many others. |

| Surface treatment method | Blacking, Sharpening, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

| Application | Precision slicing devices.Lathes machine Milling devices Grinders machine Automatic mechanical methods Automated warehousing techniques. |

| Machining method | CNC engine latheCNC milling equipment CNC drilling machine CNC grinding device Market Excavator Sprocket for DX225LCA with part variety 25718-00095A CNC slicing equipment Machining middle. |

| Module | No. of enamel | Bore (Ah7) | Hub dia.(B) | Pitch dia.(C) | Outside dia.(D) | Encounter width(E) | Hub width(F) | Whole Duration(G) |

| 1 | 18 | eight | 15 | 18 | 20 | 10 | 5 | fifteen |

| one | 55 | 15 | 40 | 55 | 57 | ten | 10 | twenty |

| 1.five | forty | sixteen | 35 | 60 | 63 | 15 | 10 | 25 |

| 2 | 50 | 22 | 50 | a hundred | 104 | twenty | 10 | 30 |

| 2.five | 60 | thirty | 70 | one hundred fifty | one hundred fifty five | 25 | 12 | 37 |

| three | 60 | 45 | eighty | one hundred eighty | 186 | 30 | 15 | 45 |

| four | 50 | fifty | 85 | two hundred | 208 | 40 | twenty | 60 |

OEM/ODM1. Associates supply drawings with 2d/3D data files.

two. Partners give samples, then our engineer will style the drawings.

SAMPLES/MASS Manufacturingone. Associates need to shell out sample fee for personalized parts, aslo we return all sample price when it reachesthe specified quantity.

two. Normally we make samples 1st to companions to verify its top quality, when they go test then wefollow samples to mass generation.

3. Normally there is 3-7days for samples creation, and 15-25days for mass generation.

Deliveryone. For sample and modest quantity purchase: By means of DHL/UPS/TNT/FedEx/and many others

two. For mass quantity(morn than 300kgs): By sea, by air or specialline. (We have benefits to shipto Russia, South The usa, other distant countries and areas)

Q: What is your conditions of payment?A: Payment=1000USD, 30% T/T in advance, balance just before shippment.

If you have any other query, 100% Motorbike Carbon Fiber Cloth Fairing Kits Chain Sprocket Swingarm Parts For KTM DUKE 690 2008-2019 remember to truly feel free to get in touch with us.

Drive shaft type

The driveshaft transfers torque from the engine to the wheels and is responsible for the smooth running of the vehicle. Its design had to compensate for differences in length and angle. It must also ensure perfect synchronization between its joints. The drive shaft should be made of high-grade materials to achieve the best balance of stiffness and elasticity. There are three main types of drive shafts. These include: end yokes, tube yokes and tapered shafts.

tube yoke

Tube yokes are shaft assemblies that use metallic materials as the main structural component. The yoke includes a uniform, substantially uniform wall thickness, a first end and an axially extending second end. The first diameter of the drive shaft is greater than the second diameter, and the yoke further includes a pair of opposing lugs extending from the second end. These lugs have holes at the ends for attaching the axle to the vehicle.

By retrofitting the driveshaft tube end into a tube fork with seat. This valve seat transmits torque to the driveshaft tube. The fillet weld 28 enhances the torque transfer capability of the tube yoke. The yoke is usually made of aluminum alloy or metal material. It is also used to connect the drive shaft to the yoke. Various designs are possible.

The QU40866 tube yoke is used with an external snap ring type universal joint. It has a cup diameter of 1-3/16″ and an overall width of 4½”. U-bolt kits are another option. It has threaded legs and locks to help secure the yoke to the drive shaft. Some performance cars and off-road vehicles use U-bolts. Yokes must be machined to accept U-bolts, and U-bolt kits are often the preferred accessory.

The end yoke is the mechanical part that connects the drive shaft to the stub shaft. These yokes are usually designed for specific drivetrain components and can be customized to your needs. Pat’s drivetrain offers OEM replacement and custom flanged yokes.

If your tractor uses PTO components, the cross and bearing kit is the perfect tool to make the connection. Additionally, cross and bearing kits help you match the correct yoke to the shaft. When choosing a yoke, be sure to measure the outside diameter of the U-joint cap and the inside diameter of the yoke ears. After taking the measurements, consult the cross and bearing identification drawings to make sure they match.

While tube yokes are usually easy to replace, the best results come from a qualified machine shop. Dedicated driveshaft specialists can assemble and balance finished driveshafts. If you are unsure of a particular aspect, please refer to the TM3000 Driveshaft and Cardan Joint Service Manual for more information. You can also consult an excerpt from the TSB3510 manual for information on angle, vibration and runout.

The sliding fork is another important part of the drive shaft. It can bend over rough terrain, allowing the U-joint to keep spinning in tougher conditions. If the slip yoke fails, you will not be able to drive and will clang. You need to replace it as soon as possible to avoid any dangerous driving conditions. So if you notice any dings, be sure to check the yoke.

If you detect any vibrations, the drivetrain may need adjustment. It’s a simple process. First, rotate the driveshaft until you find the correct alignment between the tube yoke and the sliding yoke of the rear differential. If there is no noticeable vibration, you can wait for a while to resolve the problem. Keep in mind that it may be convenient to postpone repairs temporarily, but it may cause bigger problems later.

end yoke

If your driveshaft requires a new end yoke, CZPT has several drivetrain options. Our automotive end yoke inventory includes keyed and non-keyed options. If you need tapered or straight holes, we can also make them for you.

A U-bolt is an industrial fastener that has U-shaped threads on its legs. They are often used to join two heads back to back. These are convenient options to help keep drivetrain components in place when driving over rough terrain, and are generally compatible with a variety of models. U-bolts require a specially machined yoke to accept them, so be sure to order the correct size.

The sliding fork helps transfer power from the transfer case to the driveshaft. They slide in and out of the transfer case, allowing the u-joint to rotate. Sliding yokes or “slips” can be purchased separately. Whether you need a new one or just a few components to upgrade your driveshaft, 4 CZPT Parts will have the parts you need to repair your vehicle.

The end yoke is a necessary part of the drive shaft. It connects the drive train and the mating flange. They are also used in auxiliary power equipment. CZPT’s drivetrains are stocked with a variety of flanged yokes for OEM applications and custom builds. You can also find flanged yokes for constant velocity joints in our extensive inventory. If you don’t want to modify your existing drivetrain, we can even make a custom yoke for you.

editor by czh 2023-02-16