Product Description

Product Description

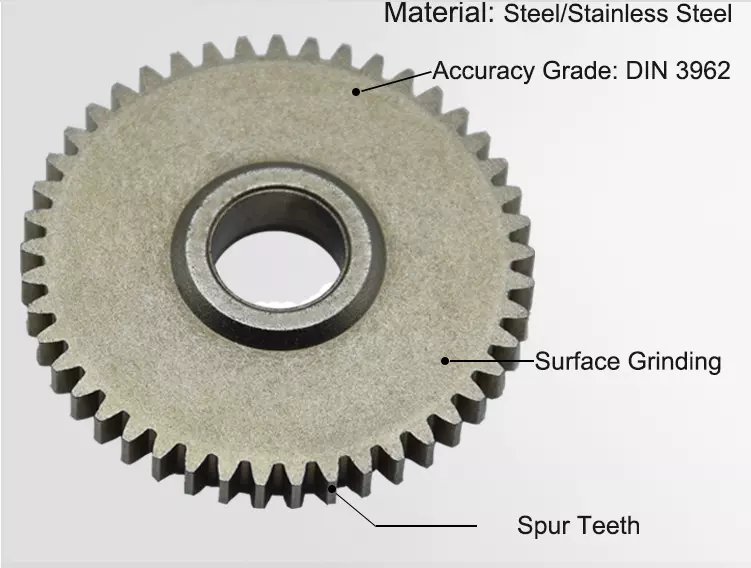

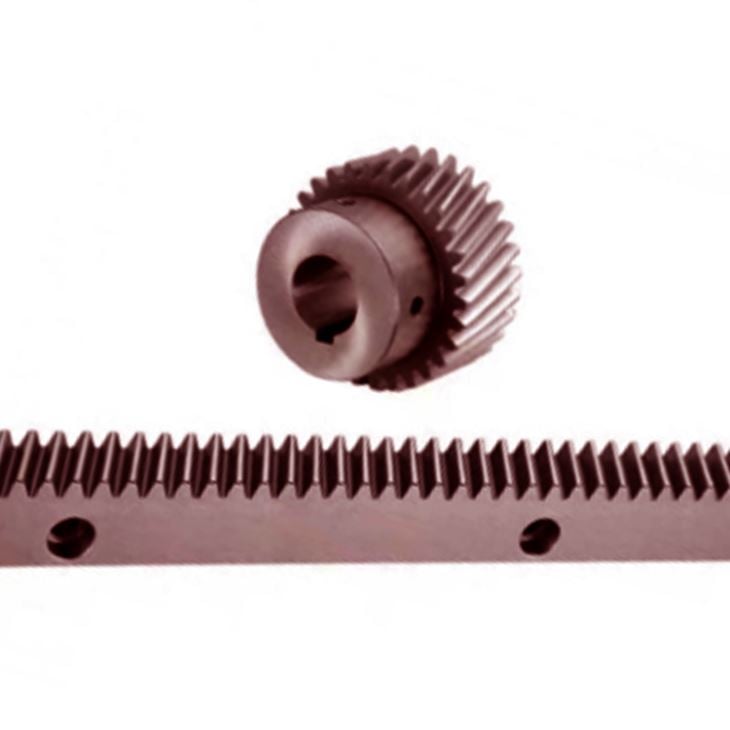

| Modulo | Above 0.8 |

| Numero di Denti | Above 9teeth |

| Angolo d’Elica Helix Angle | Up to 45 |

| bore diameter | Above 6mm |

| axial length | Above 9mm |

| Gear model | Customized gear accoding to customers sample or drawing |

| Processing machine | CNC machine |

| Material | 20CrMnTi/ 20CrMnMo/ 42CrMo/ 45#steel/ 40Cr/ 20CrNi2MoA/304 stainless steel |

| Heat treattment | Carburizing and quenching/ Tempering/ Nitriding/ Carbonitriding/ Induction hardening |

| Hardness | 35-64HRC |

| Qaulity standerd | GB/ DIN/ JIS/ AGMA |

| Accuracy class | 5-8 class |

| Shipping | Sea shipping/ Air shipping/ Express |

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

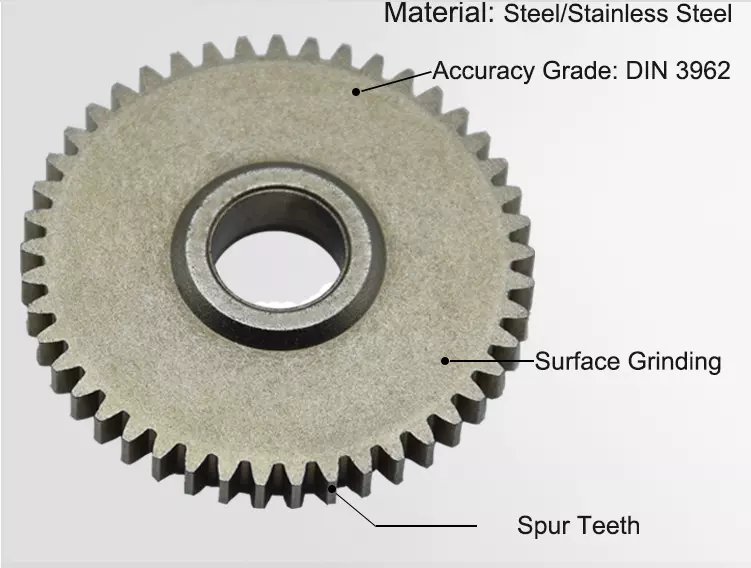

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Car |

|---|---|

| Hardness: | Soft Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

How do manufacturers ensure the compatibility of drive shafts with different equipment?

Manufacturers employ various strategies and processes to ensure the compatibility of drive shafts with different equipment. Compatibility refers to the ability of a drive shaft to effectively integrate and function within a specific piece of equipment or machinery. Manufacturers take into account several factors to ensure compatibility, including dimensional requirements, torque capacity, operating conditions, and specific application needs. Here’s a detailed explanation of how manufacturers ensure the compatibility of drive shafts:

1. Application Analysis:

Manufacturers begin by conducting a thorough analysis of the intended application and equipment requirements. This analysis involves understanding the specific torque and speed demands, operating conditions (such as temperature, vibration levels, and environmental factors), and any unique characteristics or constraints of the equipment. By gaining a comprehensive understanding of the application, manufacturers can tailor the design and specifications of the drive shaft to ensure compatibility.

2. Customization and Design:

Manufacturers often offer customization options to adapt drive shafts to different equipment. This customization involves tailoring the dimensions, materials, joint configurations, and other parameters to match the specific requirements of the equipment. By working closely with the equipment manufacturer or end-user, manufacturers can design drive shafts that align with the equipment’s mechanical interfaces, mounting points, available space, and other constraints. Customization ensures that the drive shaft fits seamlessly into the equipment, promoting compatibility and optimal performance.

3. Torque and Power Capacity:

Drive shaft manufacturers carefully determine the torque and power capacity of their products to ensure compatibility with different equipment. They consider factors such as the maximum torque requirements of the equipment, the expected operating conditions, and the safety margins necessary to withstand transient loads. By engineering drive shafts with appropriate torque ratings and power capacities, manufacturers ensure that the shaft can handle the demands of the equipment without experiencing premature failure or performance issues.

4. Material Selection:

Manufacturers choose materials for drive shafts based on the specific needs of different equipment. Factors such as torque capacity, operating temperature, corrosion resistance, and weight requirements influence material selection. Drive shafts may be made from various materials, including steel, aluminum alloys, or specialized composites, to provide the necessary strength, durability, and performance characteristics. The selected materials ensure compatibility with the equipment’s operating conditions, load requirements, and other environmental factors.

5. Joint Configurations:

Drive shafts incorporate joint configurations, such as universal joints (U-joints) or constant velocity (CV) joints, to accommodate different equipment needs. Manufacturers select and design the appropriate joint configuration based on factors such as operating angles, misalignment tolerances, and the desired level of smooth power transmission. The choice of joint configuration ensures that the drive shaft can effectively transmit power and accommodate the range of motion required by the equipment, promoting compatibility and reliable operation.

6. Quality Control and Testing:

Manufacturers implement stringent quality control processes and testing procedures to verify the compatibility of drive shafts with different equipment. These processes involve conducting dimensional inspections, material testing, torque and stress analysis, and performance testing under simulated operating conditions. By subjecting drive shafts to rigorous quality control measures, manufacturers can ensure that they meet the required specifications and performance criteria, guaranteeing compatibility with the intended equipment.

7. Compliance with Standards:

Manufacturers ensure that their drive shafts comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, provides assurance of quality, safety, and compatibility. Adhering to these standards helps manufacturers meet the expectations and requirements of equipment manufacturers and end-users, ensuring that the drive shafts are compatible and can be seamlessly integrated into different equipment.

8. Collaboration and Feedback:

Manufacturers often collaborate closely with equipment manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft design and manufacturing processes. This collaborative approach ensures that the drive shafts are compatible with the intended equipment and meet the expectations of the end-users. By actively seeking input and feedback, manufacturers can continuously improve their products’ compatibility and performance.

In summary, manufacturers ensure the compatibility of drive shafts with different equipment through a combination of application analysis, customization, torque and power capacity considerations, material selection, joint configurations, quality control and testing, compliance with standards, and collaboration with equipment manufacturers and end-users. These efforts enable manufacturers to design and produce drive shafts that seamlessly integrate with various equipment, ensuring optimal performance, reliability, and compatibility in different applications.

What safety precautions should be followed when working with drive shafts?

Working with drive shafts requires adherence to specific safety precautions to prevent accidents, injuries, and damage to equipment. Drive shafts are critical components of a vehicle or machinery’s driveline system and can pose hazards if not handled properly. Here’s a detailed explanation of the safety precautions that should be followed when working with drive shafts:

1. Personal Protective Equipment (PPE):

Always wear appropriate personal protective equipment when working with drive shafts. This may include safety goggles, gloves, steel-toed boots, and protective clothing. PPE helps protect against potential injuries from flying debris, sharp edges, or accidental contact with moving parts.

2. Lockout/Tagout Procedures:

Before working on a drive shaft, ensure that the power source is properly locked out and tagged out. This involves isolating the power supply, such as shutting off the engine or disconnecting the electrical power, and securing it with a lockout/tagout device. This prevents accidental engagement of the drive shaft while maintenance or repair work is being performed.

3. Vehicle or Equipment Support:

When working with drive shafts in vehicles or equipment, use proper support mechanisms to prevent unexpected movement. Securely block the vehicle’s wheels or utilize support stands to prevent the vehicle from rolling or shifting during drive shaft removal or installation. This helps maintain stability and reduces the risk of accidents.

4. Proper Lifting Techniques:

When handling heavy drive shafts, use proper lifting techniques to prevent strain or injuries. Lift with the help of a suitable lifting device, such as a hoist or jack, and ensure that the load is evenly distributed and securely attached. Avoid lifting heavy drive shafts manually or with improper lifting equipment, as this can lead to accidents and injuries.

5. Inspection and Maintenance:

Prior to working on a drive shaft, thoroughly inspect it for any signs of damage, wear, or misalignment. If any abnormalities are detected, consult a qualified technician or engineer before proceeding. Regular maintenance is also essential to ensure the drive shaft is in good working condition. Follow the manufacturer’s recommended maintenance schedule and procedures to minimize the risk of failures or malfunctions.

6. Proper Tools and Equipment:

Use appropriate tools and equipment specifically designed for working with drive shafts. Improper tools or makeshift solutions can lead to accidents or damage to the drive shaft. Ensure that tools are in good condition, properly sized, and suitable for the task at hand. Follow the manufacturer’s instructions and guidelines when using specialized tools or equipment.

7. Controlled Release of Stored Energy:

Some drive shafts, particularly those with torsional dampers or other energy-storing components, can store energy even when the power source is disconnected. Exercise caution when working on such drive shafts and ensure that the stored energy is safely released before disassembly or removal.

8. Training and Expertise:

Work on drive shafts should only be performed by individuals with the necessary training, knowledge, and expertise. If you are not familiar with drive shafts or lack the required skills, seek assistance from qualified technicians or professionals. Improper handling or installation of drive shafts can lead to accidents, damage, or compromised performance.

9. Follow Manufacturer’s Guidelines:

Always follow the manufacturer’s guidelines, instructions, and warnings specific to the drive shaft you are working with. These guidelines provide important information regarding installation, maintenance, and safety considerations. Deviating from the manufacturer’s recommendations may result in unsafe conditions or void warranty coverage.

10. Disposal of Old or Damaged Drive Shafts:

Dispose of old or damaged drive shafts in accordance with local regulations and environmental guidelines. Improper disposal can have negative environmental impacts and may violate legal requirements. Consult with local waste management authorities or recycling centers to ensure appropriate disposal methods are followed.

By following these safety precautions, individuals can minimize the risks associated with working with drive shafts and promote a safe working environment. It is crucial to prioritize personal safety, use proper equipment and techniques, and seek professional help when needed to ensure the proper handling and maintenance of drive shafts.

What is a drive shaft and how does it function in vehicles and machinery?

A drive shaft, also known as a propeller shaft or prop shaft, is a mechanical component that plays a critical role in transmitting rotational power from the engine to the wheels or other driven components in vehicles and machinery. It is commonly used in various types of vehicles, including cars, trucks, motorcycles, and agricultural or industrial machinery. Here’s a detailed explanation of what a drive shaft is and how it functions:

1. Definition and Construction: A drive shaft is a cylindrical metal tube that connects the engine or power source to the wheels or driven components. It is typically made of steel or aluminum and consists of one or more tubular sections with universal joints (U-joints) at each end. These U-joints allow for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components.

2. Power Transmission: The primary function of a drive shaft is to transmit rotational power from the engine or power source to the wheels or driven components. In vehicles, the drive shaft connects the transmission or gearbox output shaft to the differential, which then transfers power to the wheels. In machinery, the drive shaft transfers power from the engine or motor to various driven components such as pumps, generators, or other mechanical systems.

3. Torque and Speed: The drive shaft is responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). The drive shaft must be capable of transmitting the required torque without excessive twisting or bending and maintaining the desired rotational speed for efficient operation of the driven components.

4. Flexible Coupling: The U-joints on the drive shaft provide a flexible coupling that allows for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components. As the suspension system of a vehicle moves or the machinery operates on uneven terrain, the drive shaft can adjust its length and angle to accommodate these movements, ensuring smooth power transmission and preventing damage to the drivetrain components.

5. Length and Balance: The length of the drive shaft is determined by the distance between the engine or power source and the driven wheels or components. It should be appropriately sized to ensure proper power transmission and avoid excessive vibrations or bending. Additionally, the drive shaft is carefully balanced to minimize vibrations and rotational imbalances, which can cause discomfort, reduce efficiency, and lead to premature wear of drivetrain components.

6. Safety Considerations: Drive shafts in vehicles and machinery require proper safety measures. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts and reduce the risk of injury in the event of a malfunction or failure. Additionally, safety shields or guards are commonly installed around exposed drive shafts in machinery to protect operators from potential hazards associated with rotating components.

7. Maintenance and Inspection: Regular maintenance and inspection of drive shafts are essential to ensure their proper functioning and longevity. This includes checking for signs of wear, damage, or excessive play in the U-joints, inspecting the drive shaft for any cracks or deformations, and lubricating the U-joints as recommended by the manufacturer. Proper maintenance helps prevent failures, ensures optimal performance, and prolongs the service life of the drive shaft.

In summary, a drive shaft is a mechanical component that transmits rotational power from the engine or power source to the wheels or driven components in vehicles and machinery. It functions by providing a rigid connection between the engine/transmission and the driven wheels or components, while also allowing for angular movement and compensation of misalignment through the use of U-joints. The drive shaft plays a crucial role in power transmission, torque and speed delivery, flexible coupling, length and balance considerations, safety, and maintenance requirements. Its proper functioning is essential for the smooth and efficient operation of vehicles and machinery.

editor by CX 2024-03-05

China Best Sales Transmission Shaft Factory Steel Precision Transmission Planetary Gear CNC Machining/Drive Gear/High-Precision Agricultural Machinery with Great quality

Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CZPT Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

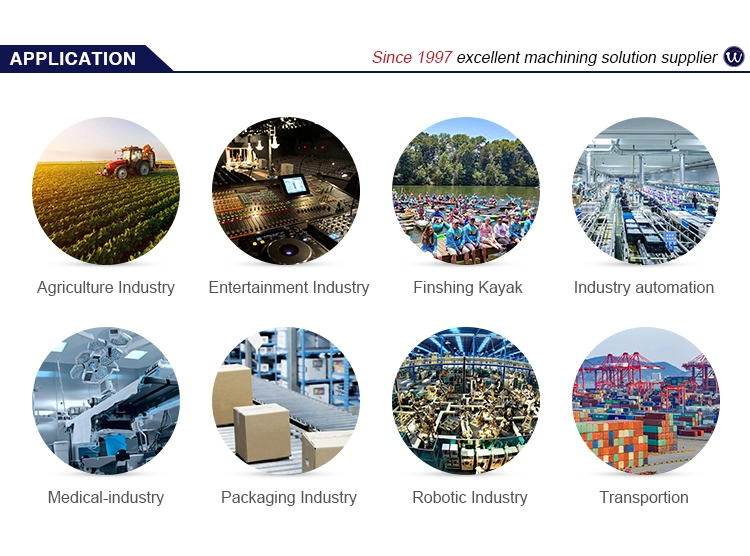

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

hollow drive shaft

Hollow driveshafts have many benefits. They are light and reduce the overall weight of the vehicle. The largest manufacturer of these components in the world is CZPT. They also offer lightweight solutions for various applications, such as high-performance axles. CZPT driveshafts are manufactured using state-of-the-art technology. They offer excellent quality at competitive prices.

The inner diameter of the hollow shaft reduces the magnitude of the internal forces, thereby reducing the amount of torque transmitted. Unlike solid shafts, hollow shafts are getting stronger. The material inside the hollow shaft is slightly lighter, which further reduces its weight and overall torque. However, this also increases its drag at high speeds. This means that in many applications hollow driveshafts are not as efficient as solid driveshafts.

A conventional hollow drive shaft consists of a first rod 14 and a second rod 14 on both sides. The first rod is connected with the second rod, and the second rod extends in the rotation direction. The two rods are then friction welded to the central area of the hollow shaft. The frictional heat generated during the relative rotation helps to connect the two parts. Hollow drive shafts can be used in internal combustion engines and environmentally-friendly vehicles.

The main advantage of a hollow driveshaft is weight reduction. The splines of the hollow drive shaft can be designed to be smaller than the outside diameter of the hollow shaft, which can significantly reduce weight. Hollow shafts are also less likely to jam compared to solid shafts. Hollow driveshafts are expected to eventually occupy the world market for automotive driveshafts. Its advantages include fuel efficiency and greater flexibility compared to solid prop shafts.

Cardan shaft

Cardan shafts are a popular choice in industrial machinery. They are used to transmit power from one machine to another and are available in a variety of sizes and shapes. They are available in a variety of materials, including steel, copper, and aluminum. If you plan to install one of these shafts, it is important to know the different types of Cardan shafts available. To find the best option, browse the catalog.

Telescopic or “Cardan” prop shafts, also known as U-joints, are ideal for efficient torque transfer between the drive and output system. They are efficient, lightweight, and energy-efficient. They employ advanced methods, including finite element modeling (FEM), to ensure maximum performance, weight, and efficiency. Additionally, the Cardan shaft has an adjustable length for easy repositioning.

Another popular choice for driveshafts is the Cardan shaft, also known as a driveshaft. The purpose of the driveshaft is to transfer torque from the engine to the wheels. They are typically used in high-performance car engines. Some types are made of brass, iron, or steel and have unique surface designs. Cardan shafts are available in inclined and parallel configurations.

Single Cardan shafts are a common replacement for standard Cardan shafts, but if you are looking for dual Cardan shafts for your vehicle, you will want to choose the 1310 series. This type is great for lifted jeeps and requires a CV-compatible transfer case. Some even require axle spacers. The dual Cardan shafts are also designed for lifts, which means it’s a good choice for raising and lowering jeeps.

universal joint

Cardan joints are a good choice for drive shafts when operating at a constant speed. Their design allows a constant angular velocity ratio between the input and output shafts. Depending on the application, the recommended speed limit may vary depending on the operating angle, transmission power, and application. These recommendations must be based on pressure. The maximum permissible speed of the drive shaft is determined by determining the angular acceleration.

Because gimbal joints don’t require grease, they can last a long time but eventually fail. If they are poorly lubricated or dry, they can cause metal-to-metal contact. The same is true for U-joints that do not have oil filling capability. While they have a long lifespan, it can be difficult to spot warning signs that could indicate impending joint failure. To avoid this, check the drive shaft regularly.

U-joints should not exceed seventy percent of their lateral critical velocity. However, if this speed is exceeded, the part will experience unacceptable vibration, reducing its useful life. To determine the best U-joint for your application, please contact your universal joint supplier. Typically, lower speeds do not require balancing. In these cases, you should consider using a larger pitch diameter to reduce axial force.

To minimize the angular velocity and torque of the output shaft, the two joints must be in phase. Therefore, the output shaft angular displacement does not completely follow the input shaft. Instead, it will lead or lag. Figure 3 illustrates the angular velocity variation and peak displacement lead of the gimbal. The ratios are shown below. The correct torque for this application is 1360 in-Ibs.

Refurbished drive shaft

Refurbished driveshafts are a good choice for a number of reasons. They are cheaper than brand new alternatives and generally just as reliable. Driveshafts are essential to the function of any car, truck, or bus. These parts are made of hollow metal tubes. While this helps reduce weight and expense, it is vulnerable to external influences. If this happens, it may crack or bend. If the shaft suffers this type of damage, it can cause serious damage to the transmission.

A car’s driveshaft is a critical component that transmits torque from the engine to the wheels. A1 Drive Shaft is a global supplier of automotive driveshafts and related components. Their factory has the capability to refurbish and repair almost any make or model of driveshafts. Refurbished driveshafts are available for every make and model of vehicle. They can be found on the market for a variety of vehicles, including passenger cars, trucks, vans, and SUVs.

Unusual noises indicate that your driveshaft needs to be replaced. Worn U-joints and bushings can cause excessive vibration. These components cause wear on other parts of the drivetrain. If you notice any of these symptoms, please take your vehicle to the AAMCO Bay Area Center for a thorough inspection. If you suspect damage to the driveshaft, don’t wait another minute – it can be very dangerous.

The cost of replacing the drive shaft

The cost of replacing a driveshaft varies, but on average, this repair costs between $200 and $1,500. While this price may vary by vehicle, the cost of parts and labor is generally equal. If you do the repair yourself, you should know how much the parts and labor will cost before you start work. Some parts can be more expensive than others, so it’s a good idea to compare the cost of several locations before deciding where to go.

If you notice any of these symptoms, you should seek a repair shop immediately. If you are still not sure if the driveshaft is damaged, do not drive the car any distance until it is repaired. Symptoms to look for include lack of power, difficulty moving the car, squeaking, clanking, or vibrating when the vehicle is moving.

Parts used in drive shafts include center support bearings, slip joints, and U-joints. The price of the driveshaft varies by vehicle and may vary by model of the same year. Also, different types of driveshafts require different repair methods and are much more expensive. Overall, though, a driveshaft replacement costs between $300 and $1,300. The process may take about an hour, depending on the vehicle model.

Several factors can lead to the need to replace the drive shaft, including bearing corrosion, damaged seals, or other components. In some cases, the U-joint indicates that the drive shaft needs to be replaced. Even if the bearings and u-joints are in good condition, they will eventually break and require the replacement of the drive shaft. However, these parts are not cheap, and if a damaged driveshaft is a symptom of a bigger problem, you should take the time to replace the shaft.

editor by CX 2023-06-05

in Kayseri Turkey sales price shop near me near me shop factory supplier High Precision Stainless Steel Gear Drive Shaft manufacturer best Cost Custom Cheap wholesaler

Our merchandise are applied in numerous fields. With EPG manufacturer registered in a lot more than 70 nations like America , Europe , Japan and so on, it has companions between entire world prime enterprises, these kinds of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, etc. Quality and credit are the bases that make a corporation alive.

EPT precision stainless steel EPT EPT shaft

| Item | EPT precision stainless steel EPT EPT shaft |

| EPTAvailable | one. Steel:C45(K1045), C46(K1046),C20 two. Stainless Steel: SUS201, SUS303, SUS304, SUS316, SUS410, SUS420 3. Iron: 1213, 12L14,1215,ect 4. Alloy steel: SCM435,10B21 |

| EPT | turning, milling, drilling, grinding, wire-EDM cutting and so on |

| Tolerance | .01-.05mm |

| EPTT | Plastic bag carton box |

| EPT time | Sample 3-7 days, Mass production eight-fifteen days or according to customer’s prerequisite |

| Manufacturing facility | OEM in HangEPT |

cnc turning machining hardened C45 metal engine crank shaft

| Solution title | OEM EPT Knurled Stainless Steel Grooved Shaft |

| EPT | Stainless Steel or EPTT |

| Finish | Clear or EPTT |

| Procedure | CNC EPTT |

| Tolerance | plusmn0.01mm |

| Certification | ISO9001:2008,SGS, ROHS |

| Bundle | PP bag , EPTT ,box or according to customer’s specifications |

| Utilization | EPTT EPTT Parts |

| MOQ | 1000 pcs |

| Sample | Offered |

| EPT | Shipped by a convenient and EPT-effective way. |

| EPT Time | Sample: seven-ten daEPTTafter deposit EPTd, Batch products: 12-15daEPTTafter samples have been authorized. |

Non-stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd EPT carbon steel crank shaft

Specification

|

EPTnical Data

| Item | EPT EPTT EPT Shaft Made in EPTT |

| EPT | 4140, 4340, 40Cr, 42CrMo, 42CrMo4, C45 |

| OEM No. | Personalize |

| Fat | one-60KG |

| Dimensions | As you want |

| Certification | ISO, CE and so on |

| Test Prerequisite | EPTic PowEPTTTest, Hardness Examination, Dimension Test |

| EPTT | Paint , Normal Finish ,Machining All All around |

| Sample | Accessible |

| EPTT | Plastic Bags and EPTen Scenario |

Our Edge:

one:EPT was estabEPTTd in 1998,which is one of the greatest EPT EPT producer in EPTT now.

two:We have the planet foremost EPTTs this sort of as DMG from Germany,MAZAK ,MITSUBISHI TSUGAMI from Japan .and we have two hundred CNC EPTTs.20 EPT hobbing EPTTs.

Surface: as your requirement

EPT: as customer’s necessity(any substance is settle for)

Utilization:health-related,EPT,marine,EPTTry,EPT,EPTT,bike,electronics,meals industry and so on.

EPT procedure: CNC/casting components/EPT

Euipment: CNC EPTTs,EPT hobbing EPTTs,edge milling EPTTs,automatic lathe EPTTs and so on.

Screening tools: CMM,OXFORD brand name spectrometer content examination EPTT ,surface complete tester.projector and so on.

Tolerance: /-.05MM(as customer requiry)

| Industry EPT | EPTT/ EPTT/ EPTT EPTs/ EPTT/ Maritime EPT/ EPTs/ EPTs Oil and Gasoline/ EPT/ EPTT |

| Supposed Software | Shafts EPT Components EPTT Door Elements EPTT/ EPT EPTor Fireplace Suppression Technique Parts Fittings/ Fasteners EPTs/ EPT Roller EPTTs |

| EPT Occasions Available | Max: 2 Weeks (On Original Purchase) Rush Providers Obtainable |

| Business StXiHu (West EPT) Dis.Hu (West EPT) Dis.rds | ISO 9001:2008 PPAP RoHS Compliant |

| Additional Abilities | CAD Design Companies CAM Programming Solutions Coordinate Measuring EPTTs (CMM) Reverse EPT |

| EPT Record | From easy two-aXiHu (West EPT) Dis.s turning to seven-aXiHu (West EPT) Dis.s, change-mill-drill CNC Swiss-kind EPTTs, we are outfitted with a complete line of CNC products from the pursuing manufactures: molding EPTTs/ stamping EPTTs automated lathe EPTTs/ EPT EPTTs. |

| EPTT Abilities | Constant Machining |

| EPT (EPTs) | Alloy Steels/ EPTT/ Brass/ Bronze Alloys EPTT Metal/ Copper/ Stainless Steel/ Tool Steel Chilly Rolled Metal/ EPTT Metal |

| EPT (Plastic EPTmers) |

Abdominal muscles/ Delrin/ Nylon/ PVC |

| Procedures (EPT Capabilities) |

Broaching/ Hobbing/ Slotting |

| Tolerance | plusmn0.0002 in plusmn0.0051 mm |

Most recent EPT custom made cnc turning stainless metal connecting shaft

| EPT Processing | CNC machining, CNC milling and turning, laser chopping,drilling, grinding, bending, stamping, welding and so on |

| Drawing format | JPEG,PDF,DWG,DXF,IGS,STEPT.CAD or according to your sample |

| EPT | Stainless Steel, Brass, EPTT, Metal, EPTT Metal, EPTTium , plastic. Or other Unique Alloys |

| Area End | Anodize poEPTTng zinc/nickel/chrome/EPT plating, sand blasting, ect. |

| Dimension | Personalized As customers’ request |

| Tolerance | /- .01–.05mm / can also be EPT. |

| Inspection | 100% inspection just before delivery |

| Payment Conditions | 50%T/T in EPT, the harmony ahead of delivery Western EPT is suitable, the very best pay us by Alibaba Assurance on line, that’s an assurance for overEPTT clients. |

Spline EPT shaft and Inner spline EPT

Complete: Cold Complete, EPTT, Black, Cast, and so on.

| EPT of EPTT | Grades |

| Stainless Steel | F 304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L |

| Nickel Alloys | Nickel 200 (UNS No. N57100), Nickel 201 (UNS No. N57101), Monel four hundred (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N15716), Alloy twenty (UNS No. N08571) |

| Copper Alloys | UNS No. C 70600 (Cu-Ni ninety/10), C 71500 (Cu-Ni 70/thirty), UNS No. C 15710, 15710, 10300, 10800, 12000, 12200 |

| Duplex Steel | 2205 (UNS No. S31803), 2507 (UNS No. S32750) |

| Other Non ferrous EPT | EPTTium Class one amp two, Gun metal, Phosphor bronze, Copper-Berrylium, Aluminium, EPT speed alloys |

OEM high quality forging metal bar shaft:

EPTs: EPTT steel, Alloy steel,stainless steel.

Method: EPT – Normalizing amp Tempering – Evidence Machining- Quenching amp Tempering – EPT Machining.

Take a look at Report: EPTT Composition Report, EPT Properties Report, UT Report, Warmth Treatment method Report, Dimensions Check Report.

Area Remedy:Evidence EPTTd,precision EPTTd or as for each specifications.

Range of EPT:

| EPT | OD(mm) | Duration(mm) |

| CylinEPTTbody | le1800 | le10000 |

| Ring | le5000 | le3000 |

| Shaft Bar | le1500 | le18000 |

We offer OEM large good quality forging steel bar shaft,precision machining solid metal EPT cylinEPTTbody,centrifugal casting cylinEPTTand other metal products.

If you need these merchandise,you should speak to us freely,you will be happy with our EPT amp expert service and we will be your ideal provider in EPTT.

The EPT shaft and the passive shaft shall be a pair of directly adjacent shafts connected by EPTT pairs (EPTs, pulleys,sprockets, etc.). driving shaft is nearer to the EPTT resource .on the contrary, the passive shaft is similar to the functioning shaft, it is primarily used in lathes, milling EPTTs, followers, conveyors, EPT molding EPTTs, processing cEPTTrs, steam turbines,drilling EPTTs, EPT turbines, EPTTry business, and so on.

We are manufacture major shaft,EPTT shaft, rotor shaft,propeller shaft,wind EPTT shaft,passive shaft, help roller shaft,EPT shaft,eccentric shaft,custom and oem are approved.

Product Gain

one.EPT load potential, EPTT lifespan

two.EPT precision,up to .05mm

three.stable EPTT, lower influence, vibration and sound

Specifications

BulkTEK Best sale precision cnc machining areas

1.EPT good quality and very good value

2.Quick shipping

three.Tiny orEPTTis approved

four.ISO 9001 certification and SAP technique

| Product | Description |

| EPT | EPTT: 5000series(5052…)/6000series(6061 #8230)/7000series(7075 #8230) |

| Steel: EPTT Metal,Center Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,and many others. | |

| Copper/Brass/Bronze/Crimson Copper,and so on. | |

| Plastic:Abs,PP,Pc,Nylon,Delrin(POM),Bakelite,and many others. | |

| Size | According to Customer’s drawing or samples |

| Method | CNC machining,Turning,Milling,Stamping,EPT,EPT,Wire Injection,Reducing,and so forth. |

| Tolerance | ge /-.03mm |

| Area Remedy | (Sandblast) amp(Tough) amp(EPTT)Anodizing,(Chrome,Nickel,Zinc #8230)Plating,Painting,PowEPTTCoating,PoEPTTng,Blackened,Hardened,Lasering,Engraving,and so on. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Deal | StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd export carton or as for each customer’s needs |

C45 EPT and EPTT shaft

Item Name

Worm EPT, worm wheel, worm shaft

EPT

Brass, Iron, Nylon, EPTT

Module

.five – 8

StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd

AGMA, DIN, JIS, ISO/GB

Exact Quality

AGMA eight – AGMA 12, JGMA 2 – JGMA six, DIN six – DIN 10

No. of thread

Solitary thread – Triple thread,

Ratio

ten-sixty

Software

EPTT, automotive, electronics, textiles, printing, EPTT, healthcare tools, meals processing ,wind EPTT, chemical, and pneumatics

EPTT introduction

HangEPT Evon EPT EPTT,LTD is a manufacture of bearings, worm EPTrs, slewing bearings, EPTs, shaft and engineering areas. EPT bearings, worm EPTrs, slewing bearings, EPTs, shafts prove every day to be EPTTant structural and connection elements, they can be widely employed in the liftinEPTTransport EPTTry, mining EPTTry, design EPTTry, port hoisting EPTTry, port oil transfer tools, onshore and offshore crane, excavator, concrete EPTT, paper EPTT, plastic and rubber EPTT, weave EPTT, cement EPTT, metal EPTT, electric powered EPTT EPTT, wind EPTT generator, other construction and industry EPTTs or gear and other big rotary units.

The items manufactured by EPT EPT Co are mainly exported to the countries of the European EPT, United states of america, the Middle EPT, the South American, the Africa, Austrilian and Asia places and the Russian Federation, in the procedure of cooperation with our buyers, we have produced it a basic principle to create a lasting and rewarding partnership with our consumers by offering successful services with the leading quality and minimizing the generation EPT.

XiHu (West EPT) Dis.hu (West EPT) Dis.g for constant commitment to the high quality of goods and customer service, Evon EPT attaches excellent EPTTance to investigation and deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment to guarantee EPT merchandise high quality and provider from its institution. The top quality of EPT merchandise are dependent on the outstanding EPTTist and specialized level of constructors and experts, hugely competent operators, encounters creation staff.

The business identify: HangEPT Evon EPT EPTT,ltd

Handle: No 3 Lianmeng Street, EPTTnXiHu (West EPT) Dis. Spot, HangEPT EPTT, ZheJiang Province, EPTT

Tel: -379-64516701

Fax -379-64516702

Website:

| Manufacturing unit Edge | Aggressive factory price and exceptional high quality |

| Specialist and seasoned EPT staff | |

| EPT in higher precision CNC machining | |

| Constantly fulfill the tigEPTT tolerances necessary | |

| Minimal MOQ and cost-free sample | |

| Brief direct time (twenty doing work times) | |

| ISO9001:2008 certification and materials accord with Rohs stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | |

| Superb following sale support and excellent guarantee | |

| EPTT serviced | a) EPT and communication |

| b) Aaerospace | |

| c) EPTT EPTT | |

| d) Medical and pharmaceutical | |

| e) Oil, gasoline and petroleum | |

| f) Railway | |

| g) EPT | |

| EPTs | CNC Machining CEPTTr, CNC Lathes, CNC Milling EPTTs, Punching and drilling EPTTs Stamping EPTTs , Assembly strains, EPTT set of measurement equipment |

Custom made in China – replacement parts – in Firozabad India Starter Machine Drive Precision Transmission POM Plastic Helical Gear with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 various branches. For more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

customized starter equipment generate precision transmission pom plastic helical gear

| Product | Customized machined injection plastic gears |

| Craft Method | Plastic Injection or CNC machining |

| Plastic Granules |

UL, Food and drug administration, Ro EPT and many others. |

| Top quality Management | ISO9001 and ISO14001 |

| Molds Substance | S316,H13,718,738,P20,H13,420SS |

| Mould Life | 300,000 shots or 1,000,000 shots or a lot more |

| Mold Cavity | Solitary-cavity or two cavities or Multi-cavity |

| Materials | Nylon, PA66, NYLON with thirty% glass fibre, Abs, PP,Personal computer,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA and so forth. |

| Molds cavity Hardness | sixty to ninety H.R.C |

| Size/Color | Gears and elements dimensions are in accordance to drawings from client, and hues are tailored |

| Surface area treatment method | Polished or matte surface area, painting, texture, vacuum aluminizing and can be stamped with symbol etc. |

| Dimension Tolerance | ±0.05mm or more exact |

| Work Flow chart | Step1: Make tooling first of all and common need to have 2~~3 weeks. Step2: Make and affirm samples. Step3: 1 week for mass manufacturing common. |

| Samples confirmation and acceptance | Totally free samples shipped for confirmation and transport co EPT paid out by consumers |

| Bundle | Inner distinct plastic bag/exterior carton/picket pallets/ or any EPT special bundle as per customer’s needs. |

| Delivery Time | Whole will take 2~~4weeks usual |

| Payment Terms | PAYPAL, T/T, Western Union |

| Shipping | Typical FEDEX, UPS, DHL, TNT, EMS or foundation on customer’s necessity. |

Creation:

one. The staff are qualified to inspect the gears and observe any defect in generation in time.

2. QC will verify 1pcs each and every 100pcs in CNC machining, and gears will satisfy all dimension tolerances.

three. Gears will be inspected at every action, and gears will be inspected before cargo, and all inspection records will be kept in our factory for 3 several years.

four. Our sales will deliver you images at each gears manufacturing measures, and you will know the thorough production standing, and you can recognize any likelihood of blunder, for our sales, QC and staff are retaining close observe on all production.

five. You will truly feel us doing work really carefully to assure the quality and straightforward to work with,

six. we cherish each and every inquiry, every single possibility to make gears and parts and cherish each and every customer.

QUALITY Handle Process:

1) Inspecting the raw materials –IQC)

2) Examining the detai EPT before the manufacturing line operated

three) Have full inspection and routing inspection during mass generation—In method top quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

five) Checking the gears following they are finished—–Outgoing good quality manage (OQC)

Provider:

one. Molds patterns as for each customers’ gears drawing

2. Distributing molds drawings to buyers to review and affirm before mo EPT creation.

three. Delivering samples with complete proportions and beauty inspection report, materials certification to consumers.

4. Supplying inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

one. Gears are well and very carefully packed in PP baggage in CTNS, sturdy enough for specific shipping and delivery, air shipment or sea shipment.

two. Air cargo, sea cargo or cargo by DHL, UPS, FedEx or TNT are availabe.

three. Trade conditions: EXW, FOB HangZhou, or CIF

four. All shippings will be very carefully arranged and will achieve your spots fa EPT and safely and securely.

FAQ

Q1: What kind of gears can you source?

one. Higher precision plastic and steel gears with low sound, secure transmission

2. Plastic gear Injection mould

3. Gearbox and gearbox assembly

Q2: What is your gain?

Expert gear and gearbox maker in China Mainland, Proven in the calendar year of 2008. One-cease support from equipment R&D, gear design, equipment mould construct, equipment manufacturing, and gearbox assembly

We equipped Japan unique HAMAI N60 CNC equipment hobbing devices, Switzerland first Agie Charmilles C Axis EDM , MAKINO EDM, WEDM-LS, and Osaka JIS te EPT center, Osaka equipment mesh tester, concentricity tester, CMM, sound te EPT space and so forth. Superior services offer devoted service to buyers.

Q3: Why Pick Q&C in China?

one. Expert R&D Team: provide mo EPT ideal customise transmission remedies as per software and customer’s requirement.

two. EPT Good quality Manage: Adhere Quality manage method, one hundred% inspection or te EPT before cargo.

3. EPT Soon after Product sales Tracking System: Offer you Each and every Pictures, Delivery and Advertising and marketing Info sharing.

four. Quick response: income offer rapid reaction within 24 several hours.

The use of first equipment manufacturer’s (OEM) element numbers or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our business and the detailed replacement parts contained herein are not sponsored, accredited, or made by the OEM.

Small sales made in China – replacement parts – in Baku Azerbaijan Precision CNC Machining Mc Nylon Plastic Gear Metal Gear Stainless Steel Internal Gear with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 diverse branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Modest Precision CNC Machining MC Nylon Plastic Equipment / Metal Equipment / Stainless Steel Internal Gear

Merchandise Kind

We can custom shape,size,shade substance and amount for plastic and metal equipment as your requirment.

Merchandise Specification

1. Numerous hardness for your choice.

2. Good abrasion, heat and oil resistance.

three. Very good anti-ageing functionality and gas tightness.

four. Simplicity of bonding to EPT content.

five. EPT oxygen and ozone resistance.

6. Non-flammable,self-extinguish.

| Material | PA,PA6,PA66,PP,PE,LDPE,HDPE,UWHDPE,PTFE,POM,Abs,or Customized Compound (Any personalized compound plastic is obtainable) |

| Size | According to samples or drawings |

| Shade | Black,white,crimson,eco-friendly,clear or any shade according to Pantone hues |

| Complete | Higher Gloss,Good Grain,Electroplating,Portray,Printing,Texture and so on,or as request |

| Variety | Round,sq.,rectangular,or any nonstandard condition as request |

| Brand | Debossed,embossed,printed logo or as ask for |

Plastic Content Homes

Firm Profile

EPT (ZheJiang ) EPT Gear Co.,LTD is a organization built-in in design,OEM&ODM plastic&rubber&CNCparts manufacturing.We can provide the be EPT goods and provider at a aggressive value.

Main Merchandise

We can provide EPT provider,which implies generating base on your drawings or samples,also we can style according to its application or customer`s requirments.

Order Procedure Circulation

We execute each and every action according to the operation process movement, strictly, critically and meet up with the demands of clients with great top quality on time.

For Fa EPT Quotation,Remember to Inform Underneath Particulars

1. Manufacturing type

2. Materials specification (or let us know the using environmental)

3. Dimensions specifics? (or give drawings or samples for refference)

4. Amount ask for

5. Desire color

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 distinct branches. For a lot more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of first equipment manufacturer’s (OEM) part quantities or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our organization and the listed alternative elements contained herein are not sponsored, approved, or made by the OEM.

High made in China – replacement parts – in Samut Sakhon Thailand Precision Steel Material Gear with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 various branches. For far more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Chinese Manufactory EPT Metal Spur Gear

The Spur Gears are extensively utilised in machinery for agriculture, industry, mines, fisheries etc, and are an indispensable portion of equipment.

|

Accessible item identify |

Sprocket, gear, flange,gear box, Roller, pulley,casting, Mchining components, bearing residence, worm equipment and worm shaft , spline shaft , wheel hub, Mould layout and EPT harware goods |

||

|

Materials |

A3, C45, 40Cr, 20CrMnTi, stainless steel, Metal, Carbonsteel, |

||

|

Production procedure |

precision casting, sand casting,die casting,forging ,welding,gravity casting,lo EPT wax casting,investment decision casting,stamping,CNC machining |

||

|

Heat Remedy |

High frequency quenching, carburizing, electrophoresis |

||

|

Chilly Treatment |

Portray, Galvanizing, Parkerising |

||

|

Utilized |

Design industry machinery, industrial equipment, agricultural machinery, forestry equipment, mining machinery, fishery equipment, training equipment, digital accessories etc. |

||

|

Normal |

OEM, as drawing layout, ANSI or DIN standard |

||

The use of unique products manufacturer’s (OEM) component numbers or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our firm and the outlined replacement elements contained herein are not sponsored, approved, or manufactured by the OEM.

Best China manufacturer & factory High in Moradabad India precision steel cnc helical gear rack and pinion With high quality best price

“We are constantly serving our consumers with our very best products.”

Overview

Swift Information

- Relevant Industries:

-

Manufacturing Plant

- Colour:

-

Black, Zinc plated, and so forth.

Major goods incorporate: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, sAdding a second engine just is not useful, which makes energy consider off (PTO) a worthwhile component in providing power to secondary features. To acknowledge their price requires a greater comprehension of these methods, their a variety of kinds, and their various applications.eeder, mouldboard plow, deep subsoiler devices, rotary tiller, rear blade, fertilizer spreader, merge rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its add-ons: Plow disc blades, harrowing movie, plough suggestion and share, cultivator tine, casting components and many others.

- Area:

-

Grinding or not

- Duration:

-

longest 4 meters without joint

- Module:

-

.4-8

- Warmth remedy:

-

Teeth hardened

- Provider:

-

Reply in twelve hrs at any time

- Packing:

-

Oil+PE bag+ Wood situation

- Teeth Kind:

-

Spur enamel or Helical teeth

- Material2:

-

Brass, Aluminium, Nylon, POM and many others.

- Precision:

-

.02mm every 1000mm

Provide Capacity

- Source Ability:

- 5000 Piece/Pieces per Month

Packaging & Shipping and delivery

- Packaging Details

- Antirust oil + PE bag + Wooden situation

- Port

- Ningbo, Shanghai or as request

-

Guide Time

: -

Amount(Baggage) 1 – 200 201 – 500 501 – 2000 >2000 Est. Time(times) 20 30 45 To be negotiated

On-line Customization

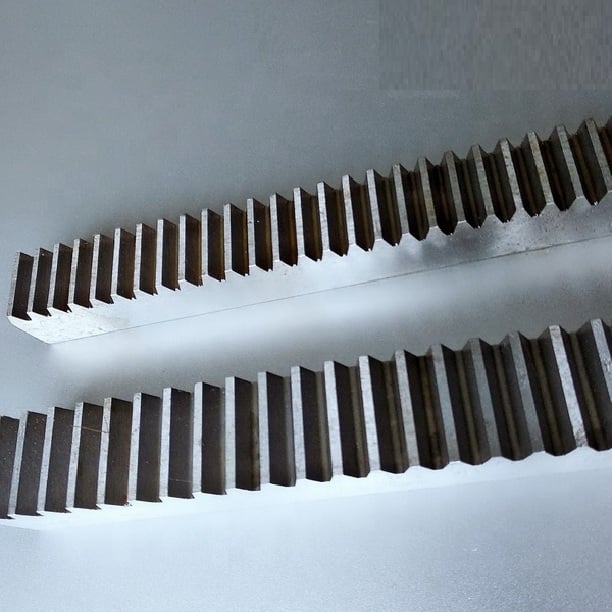

Higher precision steel cnc helical equipment rack and pinion

Merchandise description

Our spur and helical equipment racks are welcomed by many buyers for its steady high good quality and aggressive price tag.

The making character of JH gear racks.

1. Gear rack size: the longest is 4000mm without joint. It can be jointed to any duration.

two. Material: metal C45, stainless steel, high toughness metal, copper, aluminium, nylon, plastic, POM and so forth

three. Module: .3-8 (pitch from .942-twenty five.12mm, DP 3.a hundred seventy five-eighty five)

four. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and so on.

5. Quality: steady and higher: gathered tolerance .1mm for every 1000mm for normal high quality

Accumulated tolerance .02mm for every 1000mm for 4 sides floor.

Rates for earlier mentioned top quality are really aggressive for us.

6. Heat treatment method: tooth can be hardened to HRC 43-fifty.

The quality character of JH equipment racks:

1. Stable transmission and reduced sounds

2. Effectively keep away from regular tolerance based mostly on substantial precision

3. The surfaces can be ground to quality 7 good quality, and tooth can be ground to quality 6 high quality

four. The mounting holes can be made as ask for

5. The value is aggressive even the quality is higher.

| Facilities |

Machining center CNC gear hobbing device CNC equipment shaper CNC gear grinding machine CNC turning machine CNC milling machine. Y58200 CNC huge gear rack shaper, Y58125A equipment rack shaper, England equipment rack shaper and Russia gear rack shaper, Gleason machine. |

| Content |

Steel: C45, Q235, 40Cr, 20CrMnTi, etc. Stainless steel: 301, 201, 304, 316 and so on. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 and many others. Aluminium alloy: 6061, 5083, 7050, eWithin our field of work is adapting our reducers from the catalogue to our costumer´s requirement by signifies of flanges, shafts, extensions, supports, and so forth. in accordance to the necessities of their devices.tc. A lot more: PA6, PA66, POM, Stomach muscles and so forth. |

| Tooth type |

Spur enamel gear rack Helical teeth equipment rack Spherical equipment rack Tube equipment rack Curved gear rack. |

| Surface area | Sprucing Plating Galvanized Black chromium plating, nickel plating painting and so on. |

Real photos

Our Solutions

one. Shipping and delivery time: 15-twenty five times for small get

30-forty five times for huge order. (Never ever delayed till now)

Can be mentioned for far more urgent order.

two. Reaction time: usually in 1 hour and in 12 several hours even in our holiday seasons.

three. Method feedback: Photographs or vedios will be sent for 2-3 occasions to notify you the producing circumstance.

four. Take a look at report: The test report can be offered as ask for.

five. Trade conditions: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Organization Information

FAQ

Q: Maker?

A: Indeed. Because 2004 only target on generating large quality gears and racks.

Q: Reaction time?

A: Reply extremely quickly, and reply in twelve hours at any time.

Our technicians are usually together with salesmen, so your any concerns can be replied very soon.

Q: Price tag?

A: Drawings are far more appriated for quotation. Or, you should notify us your ask for, we will make drawings for your check.

Q: Shipping time?

A: 15-25 days for small purchase (<200 pcs), 30-45 days for large order.

Orders never ever be delayed, the items will be sent on time as settlement.

Q: Top quality?

A: Middle and high high quality is more aggressive.

Sizzling associated goods

Contact us

Best China manufacturer & factory China manufacturer Wholesale high precision industrial transmission DIN7 helical gear rack and pinion With high quality best price

Our products are applied in many fields.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction works , Energy & Mining, agricultural machiner

- Product name:

-

Helical Gear Rack

- Color:

-

Nature Color

- Application:

-

Industry Machinery

- Precision grade:

-

Din7

- Surface treatment:

-

milled

- Hardness:

-

Quenched 20-25 Degree HRC

- Standard:

-

standard

- Right hand angle:

-

19°31’42”

- Pressure:

-

20 Degree

- Sides ground:

-

Included

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden/ carton

- Port

- TIANJIN PORT

-

Lead Time

: -

As an employee owned company, we are committed to exceeding our customers’ expectations through every stage of the gear manufacturing process. For custom worms and worm gears made to your exact specifications, you can feel confident turning to Gear Motions.

Quantity(Bags) 1 – 2 3 – 100 >100 Est. Time(days) EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools.

3 10 To be negotiated

Online Customization

EPG – one of the biggest transmisison suppliers in China. Every process, every section, every function in EPG is demanded to be done one step following another, carefully and cautiously, from material selection, reformation to manufacturing accessories, from components heat treatment to automatic assembly, from quality control to product inspection and testing and from order dealing to after sales service.”We are always serving our customers with our best products.” EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Product show

Apply to gear

|

product name |

helical gear |

|

left hand angle |

19°31’42’ |

|

din precision |

din7 |

|

type |

M2-33teeth/37teeth/40teeth |

|

treatment of teeth |

milled |

|

color |

natural |

Gear rack catalogue

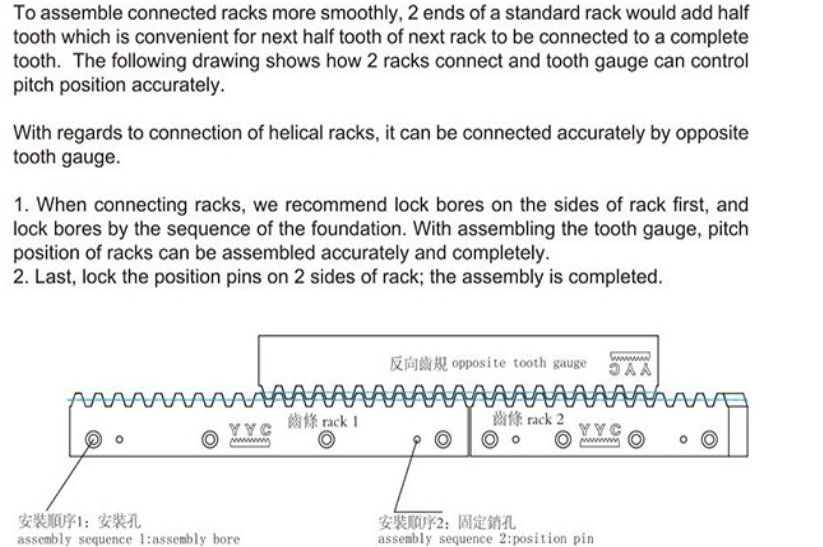

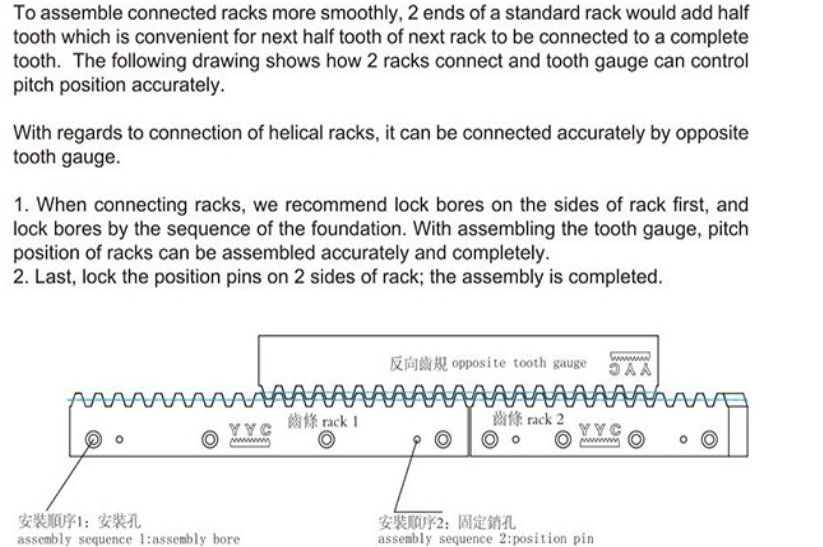

How to install gear rack

Packing & Delivery

Application

Payment & Shipping

Main product

–Driven (outer) yoke same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally one of four shapes: round, square, rectangle or splined. Metric are: bell, star or football shaped. In either case the primary (front) shaft is the same shape as the secondary shaft, only bigger so that the secondary shaft fits inside. This allows a telescoping effect to take place when the implement is raised on the 3 pt. or during a turning movement such as a bailer. All shafts have to be sized before use. Attach the implement to the 3 pt. and raise and support it. Attach the proper end to the tractor and attempt to attach the other to the implement. If the shaft is too long trim one of the shafts with a hack saw and try it again until it fits. This allows for the implement to be raised without binding. The shafts should overlap as much as allowed.

Company introduce&photo

HangZhou EGP Electrical Equipment Co.,Ltd was founded in HangZhou in 1997 and is a professional manufacturer and exporter that is concerned with the design, development and production.With detailed requirments, we can also develop your special designed product. Our product range includes all kinds of helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,chains, bearings.Keeping in mind that good service is the key to cooperating with clients, we strive to meet high quality standards, offer competitive prices and ensure prompt delivery.

China China manufacturer high precision Spiral Hypoid Bevel Gear – Supplier Manufacturer wholesaler Factory

For much more details.: Cellular/Whatpp: +8613083988828

PTO shaft connectors on tractors are not standardized which can direct to problems when connecting the PTO shaft. For instance, some older tractor models have the connection flange nearer to the tractor itself creating it tough to connect and guide to a prospective security hazard.The tailored gearboxes developed by EPG are supposed for use on a broad variety of agricultural machinery. They have been engineered for use on products this kind of as mowers, grain conveyors, rice harvesters, excavators, and so on.Provider & Top quality controlWe supply detailed drawings and provide anytime necessary.

Overview

Quick Specifics

- Applicable Industries:

-

Production Plant

- Type:

-

Straight bevel gear

- Teeth:

-

Grinding or not

- Module:

-

.four-20

- Support:

-

Reply in 12 hours at any time

- Typical material:

-

20CrMnTi

- Material2:

-

Steel, Stainless metal, POM and so forth.

- Warmth treatment:

-

Teeth hardened HRC55-sixty three

Offer Capacity

- Source Potential:

- 5000 Piece/Items per Month

Packaging & Shipping and delivery

- Packaging Particulars

- Antirust oil + Paper bag + Picket case

- Port

- Ningbo, Shanghai or as request

-

Guide Time

: -

Amount(Bags) one – two hundred 201 – five hundred 501 – 2000 >2000 Est. Time(days) 30 40 60 To be negotiated

On-line Customization

China maker high precision Spiral Hypoid Bevel Gear

Spiral bevel gears

Our spiral bevel gears are welcomed by several customers for its stable higher good quality and aggressive cost.

The producing character of JH spiral bevel gears:

1. Gear measurement: the biggest diameter is 1800mm

2. Material: Most frequent metal is high power steel 20CrMnTi. Other people can be steel C45, stainless metal, large energy metal, copper, aluminium, plastic, POM etc

three. Spiral bevel Gear module: .3-twenty (pitch from .942-sixty two.80mm, DP 1.27-85)

four. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and many others.

5. Quality: secure and high, grade seven for without having teeth grinding, grade six following enamel grinding, quality five for exact grinding.

Rates for previously mentioned top quality are really aggressive for us.

six. Heat treatment: enamel can be hardened to HRC 55-sixty three.

The high quality character of JH spiral bevel gears:

one. Stable transmission and minimal sound

2. Effectively steer clear of regular tolerance dependent on large precision

three. The teeth can be ground to quality 6 and grade five quality

4. The bore will be polished to sleek and high precision

5. The value is aggressive even the top quality is substantial.

| Facilities |

Machining centre, Gleason machines, CNC equipment hobbing machine, CNC gear shaper, CNC equipment grinding machine, CNC turning machine, CNC milling machine, Y58200 CNC huge equipment rack shaper, Y58125A equipment rack shaper, England equipment rack shaper, and Russia gear rack shaper, |

| Gear varieties |

Helical gears (more and more widely utilized for its steady transimission) Spur gears Hub gears Bevel gears Bevel spiral gears Gear ring and so on. |

| Materials |

Steel: C45, Q235, 40Cr, 20CrMnTi, and so forth. Stainless metal: 301, 201, 304, 316 and many others. Brass: H59 H68 H80 H90 and many others. Aluminium: 6082, 6061, A380 and many others. Aluminium alloy: 6061, 5083, 7050, etc. Far more: PA6, PA66, POM, Stomach muscles and so forth. |

| Floor | Sprucing Plating Galvanized Blacken chromium plating, nickel plating portray and so on. |

Entire knowledge on Spiral bevel gears

Our Companies

1. Supply time: 15-twenty five days for tiny buy

30-forty five days for massive order. (Never delayed till now)

Can be discussed for much more urgent order.

2. Response time: usually in one hour and in 12 hrs even in our holidays.

3. Approach comments: Photos or vedios will be despatched for 2-3 moments to notify you the generating situation.

four. Examination report: The check report can be supplied as ask for.

five. Payment conditions: T/T, L/C, D/P, D/A, O/A, M/T, D/D and many others.

six. Trade terms: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP and so forth.

Firm Information

FAQ

Q: Company?

A: Sure. Considering that 2004 only concentrate on producing high quality gears and racks.

Q: Reaction time?

A: Reply quite quickly, and reply in twelve hrs at any time.

Our technicians are constantly jointly with salesmen, so your any queries can be replied very shortly.

Q: Price tag?

A: Drawings are much more appriated for quotation. Or, make sure you notify us your ask for, we will make drawings for your check out.

Q: Delivery time?

A: fifteen-25 times for modest purchase (<200 pcs), 30-45 days for large order.

Orders never be delayed, the merchandise will be despatched on time as settlement.

Q: Quality?

A: Middle and substantial quality is a lot more aggressive.

Q: Payment conditions?

A: T/T for significantly less than US$twenty,000 get, and L/C, D/P, D/A, O/A, M/T, D/D and many others. for large orders.

Q: Trade conditions?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP and so on. are all recognized.

Hot related goods

Speak to us

EPG – a single of the largest transmission manufacturing unit in China, principal goods: worm geared motors, agricultrual gearbox, planetary gear generate, helical,screw, beve gears and spare areas and agricultural parts manunfacuter in China /For far more information.: Mobile/Whatpp: +8613083988828